Executive Summary

Integrated fixed film activated sludge (IFAS) is a relatively new technology that describes any suspended growth system that incorporates an attached growth media within the suspended growth reactor (U.S. EPA 2010). Biofilm carriers are generally divided in ‘dispersed media’ or ‘fixed media’. This technique, used in highly developed wastewater treatment plants, can be used as an upgrade for existing facilities or can be constructed newly. The design needs expert knowledge and the system must be operated by skilled labourers.

| In | Out |

|---|---|

Blackwater, Faecal Sludge, Greywater, Brownwater, Non-biodegradable Wastewater, Energy |

Fertigation Water, Treated Water |

Introduction

(Adapted from BRENTWOOD 2009)

Integrated Fixed-film Activated Sludge (IFAS) Technology provides for additional biomass within a wastewater treatment facility in order to meet more stringent effluent parameters or increased loadings without the direct need for additional tankage. Industry practice for upgrading wastewater treatment plants usually focuses on increasing the bioreactor volume to provide the additional bacterial population required to meet the system’s kinetic needs. However, designers often encounter clarifier solids loading limitations that put an upper limit on the amount of biomass that can be carried in the suspended growth system. The advantage of biofilm processes compared to activated sludge processes is that the anaerobic, anoxic and aerobic zones can be combined in a single stage (see also rotating biological contactor, and anammox). IFAS systems allow for the additional bacterial population to exist on a fixed surface, thereby eliminating the need to increase the suspended growth population.

Basic Design Principles

Media Types

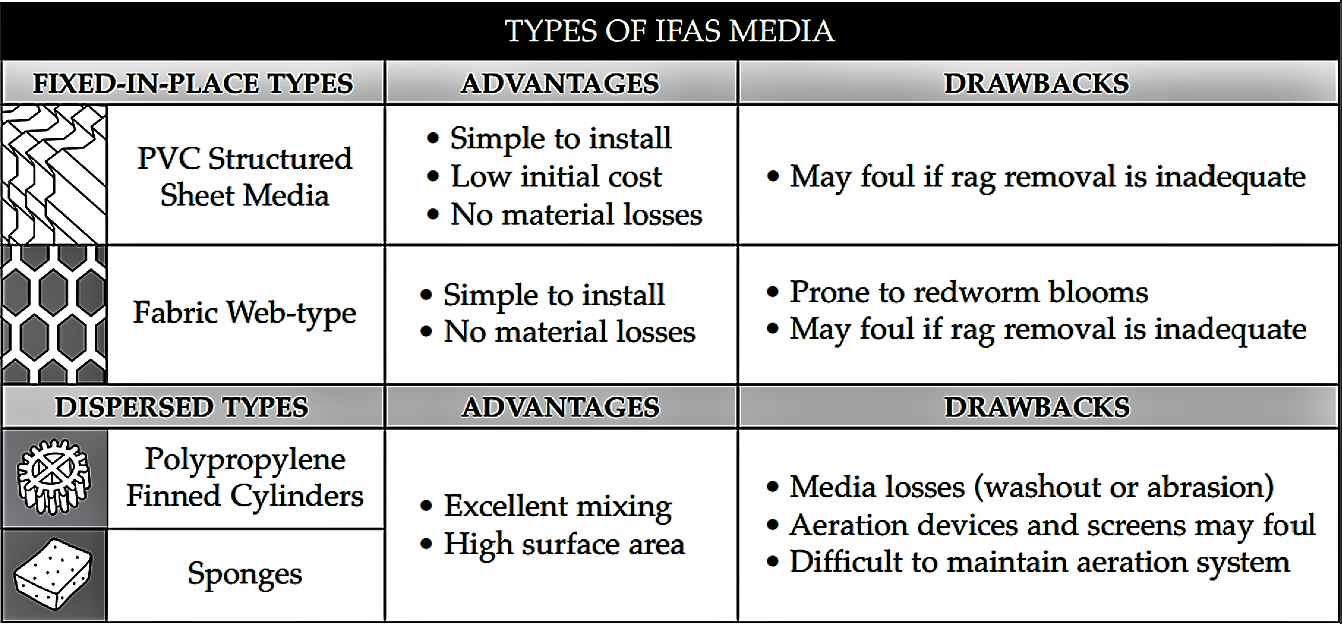

There are a number of different approaches to IFAS implementation but the various configurations fall into one of two basic types: “dispersed media” entrapped in the aeration basin, and “fixed media”, such as structured sheet media or knitted fabric media, fixed-in-place in the aeration basin (BRENTWOOD 2009).

The Process

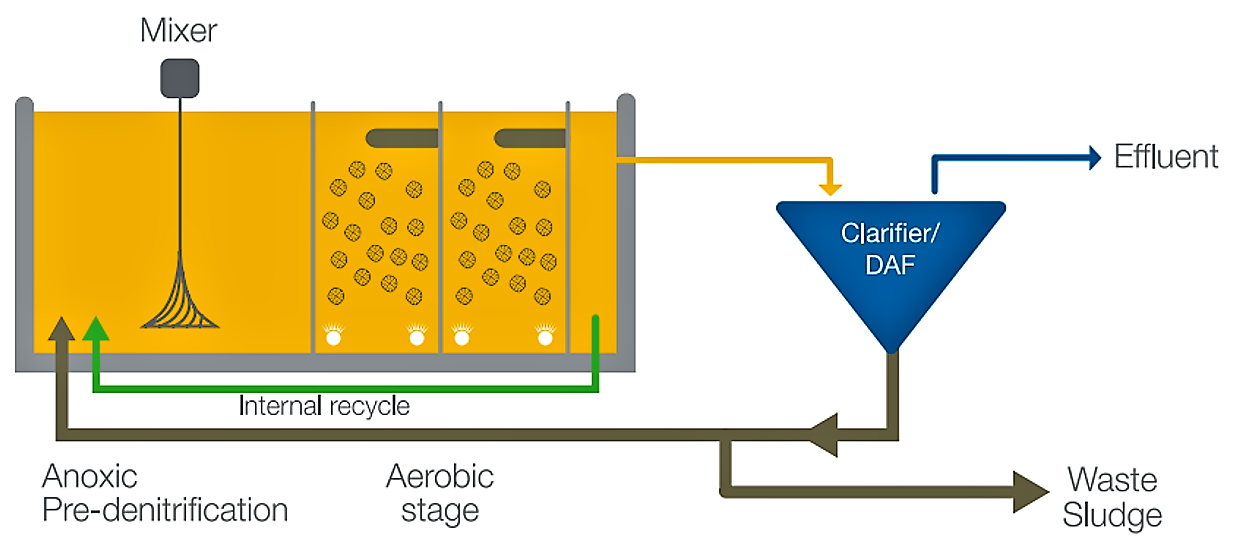

(Adapted from AQWISE 2010)

The Integrated Fixed-film Activated Sludge (IFAS) process combines the advantages of conventional activated sludge with those of biofilm systems by combining the two technologies in a single reactor (see also rotating biological contactor, anammox or trickling filters). Typically, an IFAS configuration will be similar to an activated sludge plant, with biomass carriers (described above) introduced into carefully selected zones within the activated sludge process. This allows two distinct biological populations to act synergistically, with the Mixed Liquor Suspended Solids (MLSS) degrading most of the organic load (BOD), and the biofilm creating a strongly nitrifying population for oxidation of the nitrogenous load (NH4+).

Cost Considerations

(Adapted from BRENTWOOD 2009)

IFAS vs. Conventional Activated Sludge

- For new installations, IFAS systems will generally require less volume and therefore have less capital cost than a conventional AS system.

- For retrofits of existing activated sludge (AS) systems to address increased capacity or improved biological nutrient removal (BNR), IFAS systems represent a cost-avoidance associated with the additional volume of that would otherwise be required for additional AS capacity.

- IFAS systems require little or no additional operational costs or operating staff over conventional AS. However, the need for oxygen supply remains.

Cost Comparison of Various IFAS Systems

- Dispersed systems require expenditures for additional components, such as media-retaining sieves, air knives, and/or pumps for sponge regeneration.

- Rather than solely using the media-specific surface areas a means of comparing various IFAS approaches, a true capital cost comparison of different IFAS media systems should look at the cost of removing a given NH3-N load.

- Based on the best available systems today, the treatment cost per pound of NH3-N removed per day in a fixed media IFAS system is approximately 1/3 less than the treatment cost per lb.of NH3-N removed per day in a dispersed media IFAS system.

Health Aspects

Operation and maintenance of fixed film systems is normally carried out by skilled labourers. The effluent water from the IFAS system should be clarified (see graph above) before it is discharged. Waste sludge still contains hazardous substances (e.g. heavy metals or pathogens). It should be further treated (e.g. anaerobic digestion or composting) or dewatered (e.g. mechanical dewatering or drying beds) and discharged correctly.

Operation and Maintenance

All IFAS systems, whether based on dispersed or fixed media, require adequate preliminary treatment design and operation. Primary clarification or fine screening will prevent ragging and material build-up on the media in the aeration basin and clogging of the dispersed media and retaining screens (BRENTWOOD 2009). All operational activities must be carried out by skilled labourers.

| Working Principle | It is a similar process to activated sludge, but the fixed biomass combines aerobic, anaerobic and anoxic zones and increases the Sludge Retention Time, promoting better nitrification compared to simple suspended growth systems. |

| Capacity/Adequacy | These high-tech systems are mostly used for upgrading existing treatment plants to enable extensive nitrogen removal. |

| Performance | The added biomass improves the performance of nitrifying plants, or even allows non-nitrifying plants to nitrify. |

| Costs | Very high construction and maintenance costs; operation very expensive due to requirement of permanent professional operation, high electricity consumption and costly mechanical parts. |

| Self-help Compatibility | Very low and system parts are not locally available |

| O&M | Fixed-film activated sludge units require professional operation and maintenance providers. |

| Reliability | Reliable technique if designed and operated correctly. It is resistant to organic and hydraulic shock loads but fails in case of power failures. |

| Main strength | High removal efficiency for large range of wastewaters. Can be adapted as an upgrade for existing treatment plants. |

| Main weakness | Highly mechanised system requiring expert design, operation and maintenance as well as mechanical spare parts. Large energy requirements (e.g. for aeration) and carrier type for biofilm is necessary. |

IFAS technology has been incorporated into municipal/industrial wastewater facilities for both new construction and upgraded plants in many variations of suspended growth systems. When included in new plant design, reduced tank volumes result. New tanks must be designed to incorporate fixed or dispersed media and additional auxiliary screens should be added if a dispersed IFAS media reactor is chosen (adapted from BRENTWOOD 2009).

Similarly, in retrofit applications, increased treatment capacity may be realised, along with the other benefits of fixed film type processes. The existing aeration capacity needs to be evaluated to determine whether it is adequate for the increased BOD removal and biomass respiration expected with the higher level of treatment performance associated with IFAS. Media installation needs to be planned carefully to ensure that the existing basins can accommodate the fixed media modules or dispersed media systems (adapted from BRENTWOOD 2009).

Integrated Water & Wastewater Treatment Solutions

This brochure gives you an overview about several wastewater treatment solutions.

AQWISE (2010): Integrated Water & Wastewater Treatment Solutions. Herzliya: Aqwise - Wise Water Technologies Ltd URL [Accessed: 03.06.2019]Integrated Fixed Film/ Activated Sludge (IFAS) Technology

This well assorted document gives you a great overview about the Integrated Fixed Film/ Activated Sludge (IFAS) Technology.

BRENTWOOD (2009): Integrated Fixed Film/ Activated Sludge (IFAS) Technology. Reading: Brentwood Industries, Inc. [Accessed: 16.04.2019] PDFSludge Volume Index

Nutrient Control Design Manual

The purpose of this manual is to provide updated, state‐of‐the‐technology design guidance on nitrogen and phosphorus control at municipal Wastewater Treatment Plants (WWTPs). This manual contains extensive information on the principles of biological nutrient removal and chemical phosphorus removal to serve as the basis for design. A detailed description of technologies, both conventional and emerging, serves as a resource for preliminary technology selection.

U.S. EPA (2010): Nutrient Control Design Manual. Washington, DC: United States Environmental Protection Agency URL [Accessed: 03.06.2019]Integrated Water & Wastewater Treatment Solutions

This brochure gives you an overview about several wastewater treatment solutions.

AQWISE (2010): Integrated Water & Wastewater Treatment Solutions. Herzliya: Aqwise - Wise Water Technologies Ltd URL [Accessed: 03.06.2019]Integrated Fixed Film/ Activated Sludge (IFAS) Technology

This well assorted document gives you a great overview about the Integrated Fixed Film/ Activated Sludge (IFAS) Technology.

BRENTWOOD (2009): Integrated Fixed Film/ Activated Sludge (IFAS) Technology. Reading: Brentwood Industries, Inc. [Accessed: 16.04.2019] PDFNutrient Control Design Manual

The purpose of this manual is to provide updated, state‐of‐the‐technology design guidance on nitrogen and phosphorus control at municipal Wastewater Treatment Plants (WWTPs). This manual contains extensive information on the principles of biological nutrient removal and chemical phosphorus removal to serve as the basis for design. A detailed description of technologies, both conventional and emerging, serves as a resource for preliminary technology selection.

U.S. EPA (2010): Nutrient Control Design Manual. Washington, DC: United States Environmental Protection Agency URL [Accessed: 03.06.2019]Activated Sludge and Aerobic Biofilm Reactors

Activated Sludge and Aerobic Biofilm Reactors is the fifth volume in the series Biological Wastewater Treatment. The first part of the book is devoted to the activated sludge process, covering the removal of organic matter, nitrogen and phosphorus. A detailed analysis of the biological reactor (aeration tank) and the final sedimentation tanks is provided. The second part of the book covers aerobic biofilm reactors, especially trickling filters, rotating biological contractors and submerged aerated biofilters. For all the systems, the book presents in a clear and informative way the main concepts, working principles, expected removal efficiencies, design criteria, design examples, construction aspects and operational guidelines.

SPERLING, M. von (2007): Activated Sludge and Aerobic Biofilm Reactors. (= Biological Wastewater Treatment Series , 5 ). London: International Water Association (IWA) Publishing URL [Accessed: 03.06.2019]Biological Wastewater Treatment in Warm Climate Regions Volume 2

Biological Wastewater Treatment in Warm Climate Regions gives a state-of-the-art presentation of the science and technology of biological wastewater treatment, particularly domestic sewage. The book covers the main treatment processes used worldwide with wastewater treatment in warm climate regions given a particular emphasis where simple, affordable and sustainable solutions are required. The 55 chapters are divided into 7 parts over two volumes: Volume One (also available in the SSWM library): Introduction to wastewater characteristics, treatment and disposal; Basic principles of wastewater treatment; Stabilisation ponds; Anaerobic reactors; Volume Two: Activated sludge; Aerobic biofilm reactors; Sludge treatment and disposal.

SPERLING, M. von LEMOS CHERNICHARO, C.A. de (2005): Biological Wastewater Treatment in Warm Climate Regions Volume 2. London: International Water Association (IWA) Publishing URL [Accessed: 26.05.2019]Integrated Fixed Film Activated Sludge (IFAS) System for Additional Nitrification at the Coldwater WWTP

Check out this pdf-presentation about an IFAS project, how it was designed, constructed and its performance.

FLAMMING, J. (n.y): Integrated Fixed Film Activated Sludge (IFAS) System for Additional Nitrification at the Coldwater WWTP. (= PDF Presentation ). Grand Rapids: Fishbeck, Thompson, Carr & Huber, Inc. (FTC&H) URL [Accessed: 03.06.2019]Simultaneous Nitrification and Denitrification in Biofilms of an Engineered Integrated Fixed-Film Activated Sludge (IFAS) System

The Florida coastal community of Green Cove Springs is experiencing sudden growth pressures from the expanding suburbs of the city of Jacksonsville. An engineering firm (Camp Dresser & McKee) was retained to plan a treatment upgrade of the Harbor Road Wastewater Treatment Plant. The objective was to meet a consent order from the Florida Department of Environmental Protection to meet an unionised ammonia limit of 0.02 mg/L for river discharge.

KRICHTEN, D. MCDOWELL, C. (n.y): Simultaneous Nitrification and Denitrification in Biofilms of an Engineered Integrated Fixed-Film Activated Sludge (IFAS) System. Reading: Brentwood Industries, Inc. [Accessed: 16.04.2012] PDFTwo Year Case Study of Integrated Fixed Film Activated Sludge (IFAS) at Broomfield, CO WWTP

The City & County of Broomfield wastewater treatment plant secondary treatment processes were upgraded to a new biological nutrient removal process described as Integrated Fixed Film Activated Sludge (IFAS) back in 2003 using a moving bed plastic carrier element to help grow the biomass. This allows the existing aerobic reactors to maintain nitrification during year round operation while still operating near conventional activated sludge solids retention times (SRT) one would find in just carbonaceous treatment plants. The upgraded IFAS system includes anaerobic and anoxic reactors to help meet new effluent Total Nitrogen and Total Phosphorus limits.

RUTT, K. SEDA, J. JOHNSON, C.H. (2006): Two Year Case Study of Integrated Fixed Film Activated Sludge (IFAS) at Broomfield, CO WWTP. Alexandria: WEFTEC URL [Accessed: 16.04.2012]Aqwise - Extending Nature´s Capacity

Aqwise- Wise Water Technologies Ltd. is a world leader in the development and implementation of innovative wastewater treatment solutions for the industrial and municipal markets. You can find information about Integrated fixed film/ activated sludge (AS), moving bed bio-reactor (MBBR), MBBR + AS and compact units.