Executive Summary

Anammox stands for Anaerobic Ammonium Oxidation. The process was discovered in the early nineties and has great potential for the removal of ammonia nitrogen in wastewater. The responsible bacteria transform ammonium (NH4+) and nitrogen dioxide (NO2) into nitrogen gas (N2) and water (H2O). This saves costs as less energy for aeration and no organic carbon sources (e.g. methanol or recirculated sludge) are required. During the last 20 years, many research projects were conducted on the Anammox process. In 2007, the first large-scale Anammox reactor was built in Rotterdam. It displays the vast possibilities of this new process.

| In | Out |

|---|---|

Blackwater, Brownwater, Urine or Yellowwater |

Treated Water |

The Process

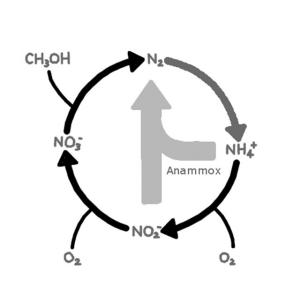

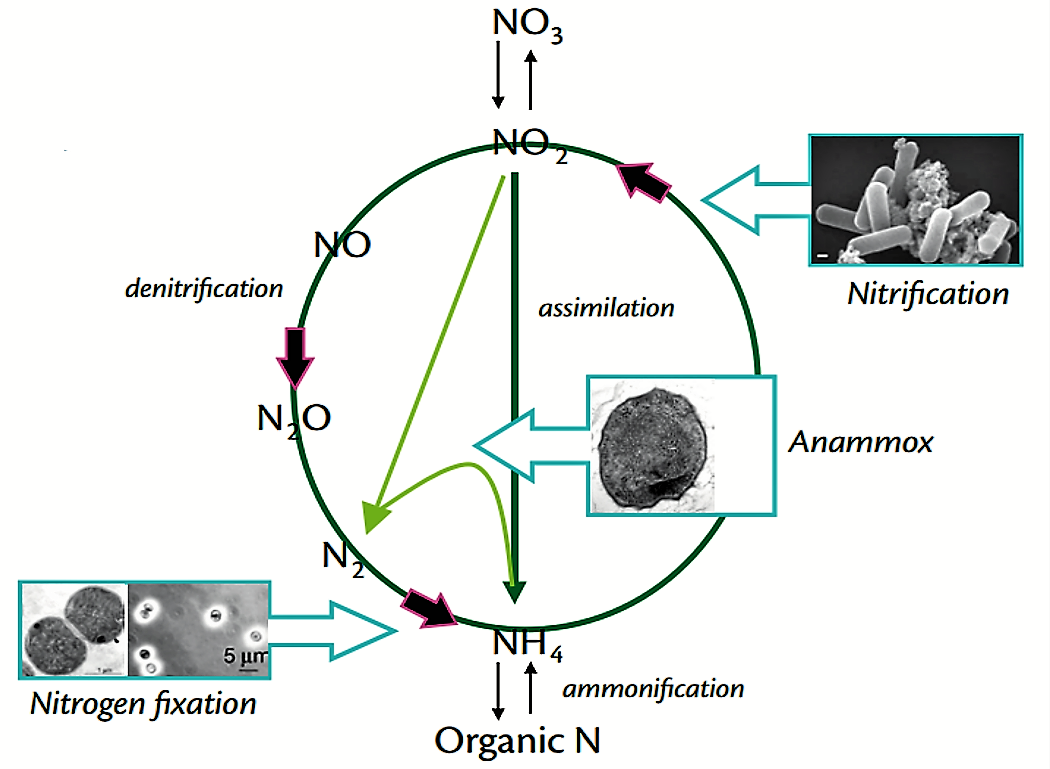

Anammox, a process of Anaerobic Ammonium Oxidation, is an innovative technological advancement in the removal of ammonia nitrogen in wastewater. This quite new process combines ammonia and nitrite directly into dinitrogen gas (SHIVARAMAN and SHIVARAMAN 2003) instead of passing through a two-stage process of aerobic nitrification and anaerobic denitrification. It was discovered about 15 years ago and has resulted in new opportunities for research and development of sustainable nitrogen removal systems. Compared to conventional nitrification/denitrification in activated sludge systems, Anammox eliminates the necessity of an organic carbon source for nitrification, reduces energy demand for aeration and has a smaller production of excess sludge and lower CO2 emissions (BERTINO 2010). The Anammox reaction can be represented as NH4- + NO2- = N2 + 2H2O. This reaction is carried out by Anammox bacteria (Candidatus Brocadia anammoxidans) belonging to the group of planctomycete (SHIVARAMAN and SHIVARAMAN 2003).

Anammox Treatment Processes

Two Reactor Nitritation-Anammox Process

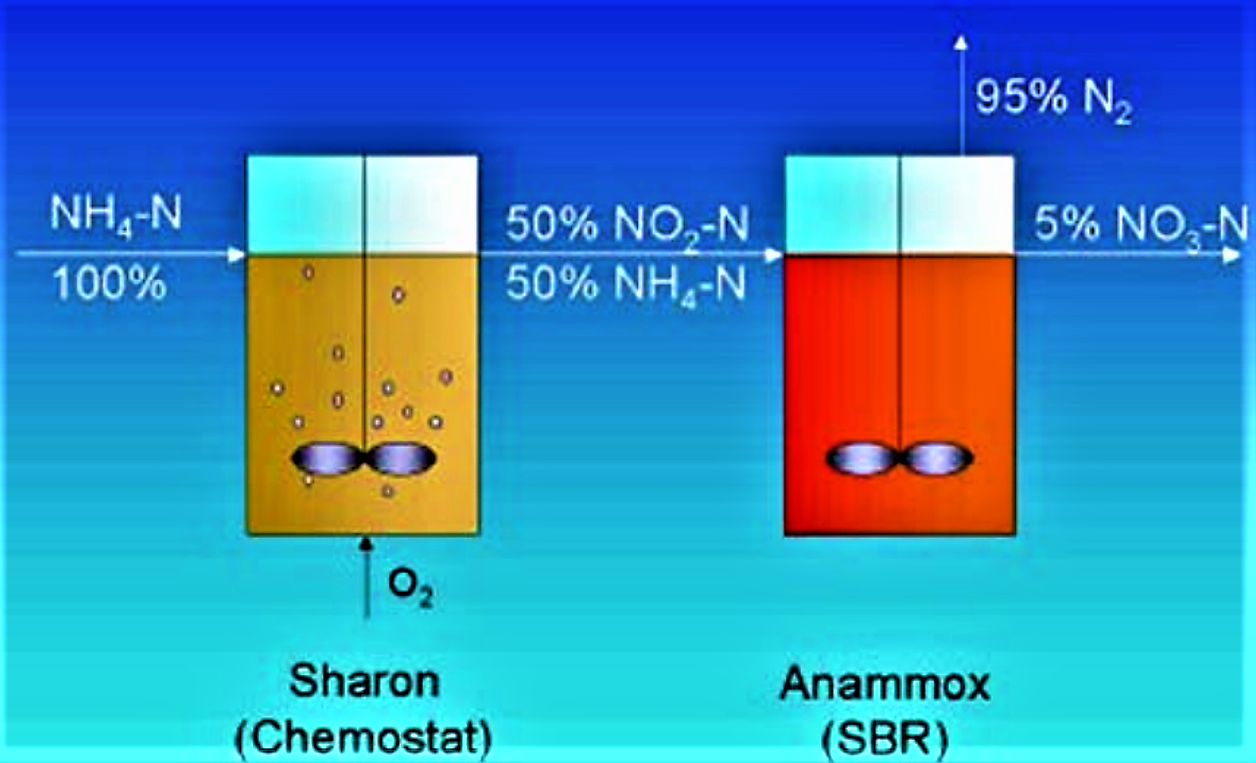

Different setups have been developed to apply Anammox in wastewater treatment. In the “two reactor nitritation-Anammox process“, ammonium is first partially oxidised to nitrite in an aerated reactor (partial nitritation). In a second stage the nitrite is reduced to elemental nitrogen using the remaining ammonium in the Anammox reactor. So far, it has only been used for ammonium rich effluents (FUX 2003; BERTINO 2010). There are alternative names for these two-stage processes, e.g. SHARON-Anammox process (XING and CLARK n.y.).

One Reactor Nitritation-Anammox Process

The one-step reactor process also has several names (see XING and CLARK n.y.). A common name is the CANON Process for ‘Completely Autotrophic Nitrogen removal Over Nitrite’ where aerobic ammonium oxidising bacteria (nitrifiers) and Anammox bacteria simultaneously perform a two-step reaction under oxygen-limited conditions in one reactor. However, this process is limited to the laboratory and pilot-plant scale due to the complex controlling conditions and the slow growth of Anammox bacteria (HUMBERT 2011).

One Reactor Denitrification-Anammox Process

This process is called DEAMOX and stands for Denitrifying Ammonium Oxidation. It is the coupling of denitrification and Anammox processes. Research is still ongoing. It can be applied to the treatment of wastewater with high nitrogen concentrations and high organic carbon levels, e.g. landfill leachate and wastewater from digested animal waste (e.g. large anaerobic digestion reactor).

Cost Considerations

The Anammox process requires much less oxygen than conventional nitrification/denitrification processes resulting in important energy savings. Because autotrophic bacteria carry out Anammox, there is no need for organic carbon sources, which saves on chemical dosage costs. The biomass yield of Anammox is very low, which saves on sludge treatment costs. However, the long start-up time and the high sensitivity of the bacteria to oxygen concentration and nitrite accumulation limit the application of the Anammox process (LI et al. 2008).

Operation and Maintenance

As it is still a new technology, operation of an Anammox reactor requires a lot of knowledge. It is a high-tech system, which needs to be monitored (temperature, load, chemical compounds of wastewater, etc.). The problems that can occur are manifold and experts must be available for maintenance. During the start-up of the first full-scale Anammox reactor in Rotterdam, the team gained a lot of experience. Read more about it in VAN DER STAR et al. (2007) .

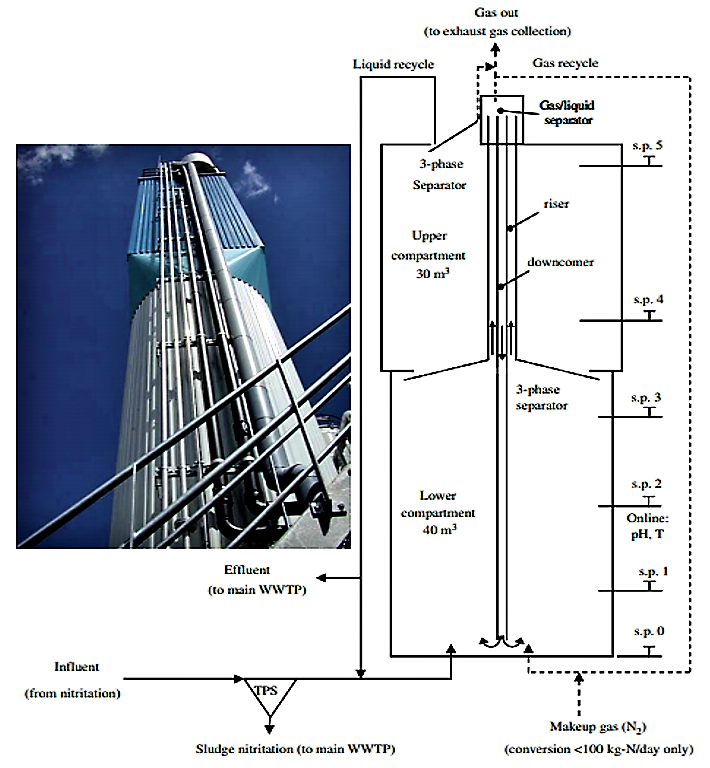

Example of Application: First Full-Scale Anammox Reactor in Rotterdam (Netherlands)

Adapted from VAN DER STAR 2007

The full-scale Anammox reactor is a 70m3 reactor designed by Paques BV (www.paques.nl). The reactor combines a high loading rate with efficient biomass retention, characteristics the Anammox process has in common with anaerobic wastewater treatment. In the lower compartment (approx. 40m3) influent is mixed with downward gas flow and gas recycled from the top of the reactor. On top of the lower compartment, gas is collected for the riser of the gas lift. The liquid moves from the lower compartment to the less mixed and thus stratified upper compartment, serving mainly for biomass retention and effluent polishing. The feed is introduced from the bottom of the reactor and is mixed with an additional recirculation flow from the effluent of the reactor when loads are lower than ca. 8m3/h or 150 kg-N/d. This allows adequate up flow velocity and shear stress to favour granule formation. The design load is 500 kg-N/d (7.1 kg-N/m3/d) but the practical maximum load is determined by the amount of nitrogen in the sludge digestate (700 kg-N/d on average).

At a Glance

| Working Principle | Anammox (Anaerobic Ammonium Oxidation) Bacteria combine ammonia and nitrite directly into dinitrogen gas. This allows a new and very efficient treatment possibility of wastewater. |

| Capacity/Adequacy | Large-scale treatment with the Anammox process is very complex in design, operation and maintenance. If the process works properly it is a great possibility to treat municipal wastewater very efficient. |

| Performance | High |

| Costs | Compared to a common nitrification/ denitrification system (e.g. activated sludge), costs are lower because no external organic source is needed and aeration requirements are much lower. |

| Self-help Compatibility | Low |

| O&M | Parameters need to be monitored frequently. |

| Reliability | High as soon as the Anammox reactor is well adjusted. |

| Main strength | Very efficient treatment and low energy use. |

| Main weakness | New technology, i.e. not a lot of knowledge available. |

The discovery of the Anammox process offers new possibilities in the wastewater treatment sector. In general, this process has the potential to replace the conventional nitrification/ denitrification steps in large-scale treatment plants.

Study on One-Stage Partial Nitritation-Anammox Process in Moving Bed Biofilm Reactors: A Sustainable Nitrogen Removal

This thesis investigates the partial nitritation/Anammox in one-stage system und oxygen limited condition (also called CANON or Deaomonification) and with the Moving Bed Biofilm Reactor (MBBR) technology. Anammox process coupled with partial nitritation can be particularly suitable to treat ammonium-rich wastewater with low content of biodegradable organic matter, such as the reject water from the dewatering of digest sludge, which is usually recirculated back to the mainstream of wastewater treatment plants, accounting for the 15-20% of total nitrogen load.

BERTINO, A. (2010): Study on One-Stage Partial Nitritation-Anammox Process in Moving Bed Biofilm Reactors: A Sustainable Nitrogen Removal. Master Thesis. Stockholm: Royal Institute of Technology (KTH) URL [Accessed: 04.11.2011]The Anammox Process for Nitrogen Removal from Waste Water

As a country bordering the Rhine, Switzerland shares in the responsibility to reduce nitrogen export to the North Sea. In wastewater treatment plants, this is currently accomplished through a costly expansion of the main activated sludge system. During the 1990s, however, there were several reports of nitrogen being eliminated rather unexpectedly under certain operating conditions. It was found that this is due to a recently discovered group of bacteria, which were also found in Swiss wastewater treatment plants. Based on this discovery, process engineers have developed a new process that reliable removes nitrogen.

FUX, C. ; EGLI, K. ; MEER, J.R. ; SIEGRIST, H. (2003): The Anammox Process for Nitrogen Removal from Waste Water. PDFDiscovery of Anammox Bacteria in Terrestrial Ecosystems

Except for this study, the Anammox (anaerobic ammonium oxidation) process has been only researched in wastewater treatment plants and aquatic environments, including sediments. Nothing is known so far about the distribution, diversity, abundance and activity of Anammox bacteria in terrestrial ecosystems. This study provides molecular evidence for the presence of Anammox bacteria in wetlands, sediments of marshes, a Reductisol profile, lake shores, a permafrost soil and a porous aquifer.

HUMBERT, S. (2011): Discovery of Anammox Bacteria in Terrestrial Ecosystems. (= PhD Thesis ). Neuchâtel: Université de Neuchâtel URL [Accessed: 04.11.2011]Recent Patents on Anammox Process

Anaerobic ammonium oxidation processes with nitrite to N2 (anammox) has become a main focus and been widely introduced as a cost-effective biological nitrogen removal way in wastewater treatment. This paper reviews various patents, which were well developed to achieve this process, such as SHARON-Anammox, CANON, and OLAND.

LI, A. ; SUN, G. ; XU, M. (2008): Recent Patents on Anammox Process. In: Recent Patents on Engineering 2008: Volume 2 , 189-194. URL [Accessed: 03.06.2019]Ammonium-oxidising bacterium

Anammox – A Novel Microbial Process for Ammonium Removal

This article gives an overview of the Anammox process and how it was discovered.

SHIVARAMAN, N. ; SHIVARAMAN, G. (2003): Anammox – A Novel Microbial Process for Ammonium Removal. In: Current Science: Volume 84 , 1507-1508. URL [Accessed: 03.06.2019]Startup of Reactors for Anoxic Ammonium Oxidation: Experiences from the First Full-Scale Anammox Reactor in Rotterdam

The first full-scale Anammox reactor in the world was started in Rotterdam (NL). The reactor was scaled-up directly from laboratory-scale to full-scale and treats up to 750 kg-N/d. With the experience of this first full-scale commercial Anammox reactor in operation, a consistent and descriptive nomenclature is suggested for reactors in which the Anammox process is employed.

STAR, W.R.L. van der ; ABMA, W.R. ; BLOMMERS, D. ; MULDER, J.W. ; TOKUTOMI, T. ; STROUS, M. ; PICIOREANU, C. ; LOOSDRECHT, M.C.M. van (2007): Startup of Reactors for Anoxic Ammonium Oxidation: Experiences from the First Full-Scale Anammox Reactor in Rotterdam. In: Water Research: Volume 41 , 4149-4163. URL [Accessed: 04.11.2011]What’s New in the Nitrogen Cycle?

This article focuses on a few of the most exciting, very recent developments in the nitrogen cycle, summarises the changes and points out some questions to guide future research. The main processes of interest are anaerobic ammonium oxidation (Anammox), aerobic nitrification by archaea, nitrogen fixation by unicellular marine cyanobacteria, and the issue of the balance and coupling between internal input and removal pathways.

WARD, B.B. ; CAPONE, D.G. ; ZEHR, J.P. (2011): What’s New in the Nitrogen Cycle?. In: Oceanography: Volume 20 , 101-109. URL [Accessed: 03.06.2019]Anaerobic Ammonium Oxidation in Waste Water - An Isotope Hydrological Perspective

The introduction of oxygen into wastewater for nitrification requires a large amount of energy. Furthermore, the carbon source is often limited in wastewater, so purchasing of carbon source (typically methanol) is necessary too. A newly discovered anaerobic ammonium oxidation (Anammox) may circumvent the limitations and open up a new possibility for nitrogen removal from wastewater. The alternative approach is a microbiological involved activity, which requires less energy and enables more efficiency on N removal.

XING, Y. CLARK, I.D. (n.y): Anaerobic Ammonium Oxidation in Waste Water - An Isotope Hydrological Perspective. Ottawa: University of Ottawa URL [Accessed: 03.06.2019]Study on One-Stage Partial Nitritation-Anammox Process in Moving Bed Biofilm Reactors: A Sustainable Nitrogen Removal

This thesis investigates the partial nitritation/Anammox in one-stage system und oxygen limited condition (also called CANON or Deaomonification) and with the Moving Bed Biofilm Reactor (MBBR) technology. Anammox process coupled with partial nitritation can be particularly suitable to treat ammonium-rich wastewater with low content of biodegradable organic matter, such as the reject water from the dewatering of digest sludge, which is usually recirculated back to the mainstream of wastewater treatment plants, accounting for the 15-20% of total nitrogen load.

BERTINO, A. (2010): Study on One-Stage Partial Nitritation-Anammox Process in Moving Bed Biofilm Reactors: A Sustainable Nitrogen Removal. Master Thesis. Stockholm: Royal Institute of Technology (KTH) URL [Accessed: 04.11.2011]The Anammox Process for Nitrogen Removal from Waste Water

As a country bordering the Rhine, Switzerland shares in the responsibility to reduce nitrogen export to the North Sea. In wastewater treatment plants, this is currently accomplished through a costly expansion of the main activated sludge system. During the 1990s, however, there were several reports of nitrogen being eliminated rather unexpectedly under certain operating conditions. It was found that this is due to a recently discovered group of bacteria, which were also found in Swiss wastewater treatment plants. Based on this discovery, process engineers have developed a new process that reliable removes nitrogen.

FUX, C. ; EGLI, K. ; MEER, J.R. ; SIEGRIST, H. (2003): The Anammox Process for Nitrogen Removal from Waste Water. PDFDiscovery of Anammox Bacteria in Terrestrial Ecosystems

Except for this study, the Anammox (anaerobic ammonium oxidation) process has been only researched in wastewater treatment plants and aquatic environments, including sediments. Nothing is known so far about the distribution, diversity, abundance and activity of Anammox bacteria in terrestrial ecosystems. This study provides molecular evidence for the presence of Anammox bacteria in wetlands, sediments of marshes, a Reductisol profile, lake shores, a permafrost soil and a porous aquifer.

HUMBERT, S. (2011): Discovery of Anammox Bacteria in Terrestrial Ecosystems. (= PhD Thesis ). Neuchâtel: Université de Neuchâtel URL [Accessed: 04.11.2011]The Discovery of the Anammox Process and Beyond

The Anammox reaction was discovered and validated to be mediated by microbes in the early nineties. In 1999, the responsible bacteria were positively identified. These slowly growing microorganisms belong to the order Brocadiales and are affiliated to the Planctomycetes. Cultivation of these bacteria at sufficient biomass density and rate, as well as the lack of pure cultures, has challenged the study of these extraordinary organisms. Membrane reactors have made the cultivation of up to 95% enriched cell suspensions of Anammox bacteria possible.

KUENEN, J.G. KARTAL, B. JETTEN, M.S.M. (n.y): The Discovery of the Anammox Process and Beyond. Pasadena: The Agouron Institute URL [Accessed: 03.06.2019]Recent Patents on Anammox Process

Anaerobic ammonium oxidation processes with nitrite to N2 (anammox) has become a main focus and been widely introduced as a cost-effective biological nitrogen removal way in wastewater treatment. This paper reviews various patents, which were well developed to achieve this process, such as SHARON-Anammox, CANON, and OLAND.

LI, A. ; SUN, G. ; XU, M. (2008): Recent Patents on Anammox Process. In: Recent Patents on Engineering 2008: Volume 2 , 189-194. URL [Accessed: 03.06.2019]Anammox – A Novel Microbial Process for Ammonium Removal

This article gives an overview of the Anammox process and how it was discovered.

SHIVARAMAN, N. ; SHIVARAMAN, G. (2003): Anammox – A Novel Microbial Process for Ammonium Removal. In: Current Science: Volume 84 , 1507-1508. URL [Accessed: 03.06.2019]What’s New in the Nitrogen Cycle?

This article focuses on a few of the most exciting, very recent developments in the nitrogen cycle, summarises the changes and points out some questions to guide future research. The main processes of interest are anaerobic ammonium oxidation (Anammox), aerobic nitrification by archaea, nitrogen fixation by unicellular marine cyanobacteria, and the issue of the balance and coupling between internal input and removal pathways.

WARD, B.B. ; CAPONE, D.G. ; ZEHR, J.P. (2011): What’s New in the Nitrogen Cycle?. In: Oceanography: Volume 20 , 101-109. URL [Accessed: 03.06.2019]Anaerobic Ammonium Oxidation in Waste Water - An Isotope Hydrological Perspective

The introduction of oxygen into wastewater for nitrification requires a large amount of energy. Furthermore, the carbon source is often limited in wastewater, so purchasing of carbon source (typically methanol) is necessary too. A newly discovered anaerobic ammonium oxidation (Anammox) may circumvent the limitations and open up a new possibility for nitrogen removal from wastewater. The alternative approach is a microbiological involved activity, which requires less energy and enables more efficiency on N removal.

XING, Y. CLARK, I.D. (n.y): Anaerobic Ammonium Oxidation in Waste Water - An Isotope Hydrological Perspective. Ottawa: University of Ottawa URL [Accessed: 03.06.2019]Reducing Wastewater Treatment Costs and Energy Consumption

While Switzerland's wastewater treatment plants are of a high technical standard, the elimination of nutrients remains costly and energy-intensive. Eawag has now further developed a biological process, which simplifies the removal of nitrogen from sludge digester liquid, reducing costs by 50% for this treatment step.

EAWAG (2010): Reducing Wastewater Treatment Costs and Energy Consumption. Duebendorf: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) URL [Accessed: 03.06.2019]Anammox case study STW Rotterdam

This short factsheet describes how an Anammox reactor replaces an existing, but old treatment system in the sludge treatment facility in Rotterdam.

PAQUE (n.y): Anammox case study STW Rotterdam. Balk: Paques BV URL [Accessed: 04.11.2011]Startup of Reactors for Anoxic Ammonium Oxidation: Experiences from the First Full-Scale Anammox Reactor in Rotterdam

The first full-scale Anammox reactor in the world was started in Rotterdam (NL). The reactor was scaled-up directly from laboratory-scale to full-scale and treats up to 750 kg-N/d. With the experience of this first full-scale commercial Anammox reactor in operation, a consistent and descriptive nomenclature is suggested for reactors in which the Anammox process is employed.

STAR, W.R.L. van der ; ABMA, W.R. ; BLOMMERS, D. ; MULDER, J.W. ; TOKUTOMI, T. ; STROUS, M. ; PICIOREANU, C. ; LOOSDRECHT, M.C.M. van (2007): Startup of Reactors for Anoxic Ammonium Oxidation: Experiences from the First Full-Scale Anammox Reactor in Rotterdam. In: Water Research: Volume 41 , 4149-4163. URL [Accessed: 04.11.2011]