Executive Summary

Drilled wells can serve as a low-cost water supply for single households, for small rural communities and for more urban areas. The working principle is rather simple: A hole is drilled into a groundwater body and infiltrating water is then abstracted with the help of a manual or motorised pump. Construction is quick and various simple drilling techniques are available suiting most geological conditions. Although drilled wells are less susceptible to contamination of groundwater compared to dug wells, adequate construction and well protection is vital to optimise a local water management system in the long run. Special attention has to be paid to the abstraction rate as environmental effects and saltwater intrusion (only in coastal areas) may occur. If the draft is too high, wells may even run dry.

| In | Out |

|---|---|

Freshwater, Drinking Water |

Introduction

Throughout the world, hundreds of thousands of hand- (or manually) drilled wells provide rural dwellers with water for agriculture, industry and domestic use. Hand drilling of water wells for domestic and productive use is very common throughout most of Bangladesh and along the Ganges plains of India. In parts of Latin America and Africa, hand-drilling technologies have been introduced more recently. In some cases, such as in Niger and Nigeria, hand drilling has become fairly well used (DANERT 2009). Despite the tremendous potential of hand drilling technologies to provide water at low cost, they are not well known by many WASH sector professionals, and in some cases are not considered to be acceptable (DANERT 2009). Hand drilling is also attractive as it can be undertaken by small, local enterprises.

Besides the manual construction, wells can also be drilled mechanically. Drilling equipment range from rather simple up to very sophisticated and powerful machines capable of drilling more than 200 metres in depth (SMET & WIJK 2002).

Particularly in regions with limited access to construction material, equipment, financial means and knowledge, machine drilling only plays a minor role as it neither shortens time for construction nor provides low-cost solutions.

How Does It Work?

The basic principle of drilled wells is simple: a hole is drilled into a groundwater body and infiltrating water is then abstracted with the help of a manual or motorised pump. Compared to dug wells, diameters of drilled wells are much smaller: In a rural context, wells are usually 50mm in diameter, while high abstraction urban supplies require holes with up to 300mm in diameter (DANERT 2009; SMET & WIJK 2002). In terms of length, manual drilled wells technically range up to 200 metres, although, a maximum length of 35 metres for hand-drilled wells is more common. For wells ranging deeper than 50 metres, manual drilling is generally no longer an option making mechanical drilling necessary.

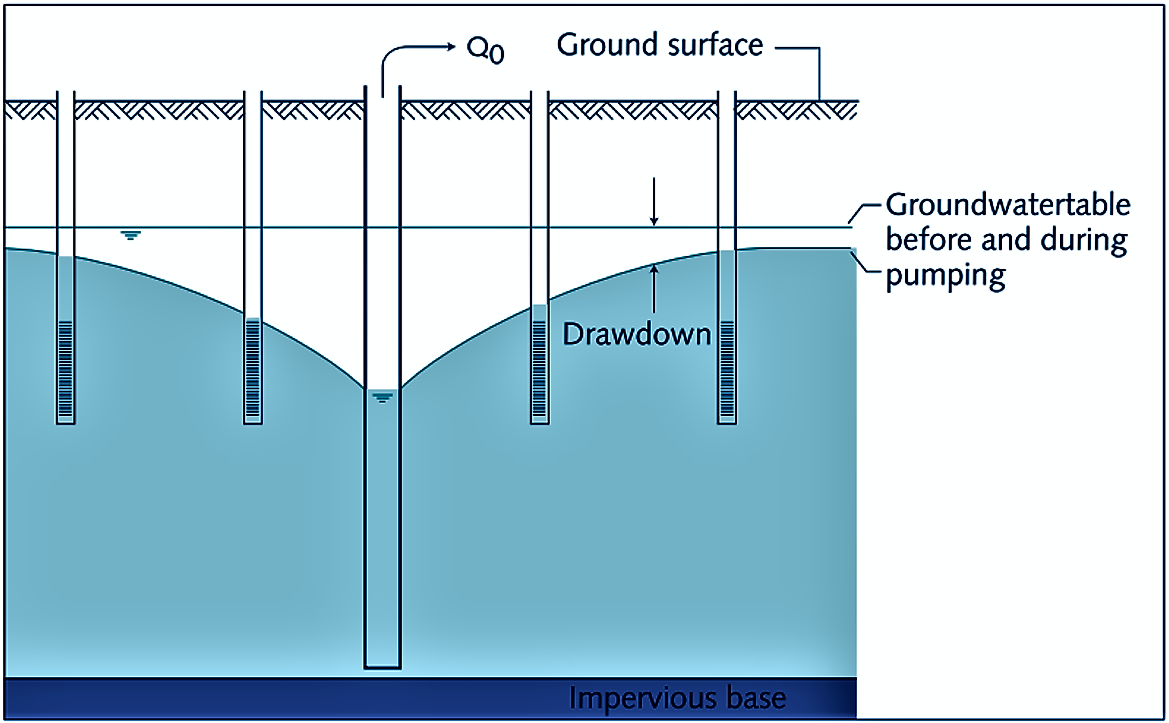

The performance of the well in terms of quantity depends on its depth and diameter, the recharge capacity of the aquifer and the development of the well. As groundwater is usually of drinking water quality, purification is often not required. Yet, drilled wells are susceptible for contamination unless properly operated, maintained and protected.

Also, strict attention needs to be paid to the abstraction rate. Overdraft can give rise to various effects on the environment:

- The water table can be lowered beyond the reach of existing wells

- Wetland can dry up

- The loss of hydraulic pressure can cause collapse of the ground and formation of craters making agricultural use impossible

- Seawater intrusion may occur if the well is located in coastal areas.

Design Principles

Initial Assessment

Before starting to design and develop any kind of water sources, an initial assessment should be conducted in order to effectively and efficiently manage and develop water resources. This assessment includes a water balance estimation (i.e. the collection of hydrological data, determination of the current status and trends of water supply, an input-output-analysis, and a water and material flow analysis) and water resources assessment (i.e. the evaluation and systematic study of water resources in relation to human impact, e.g. demand evaluation, trend estimation, analysis of water use and quality). When analysing the demand side, water allocation issues play a vital role. Eventually, this assessment can lead to a water resources development plan describing the status, the management and future development of water resources in a particular area or watershed.

Identification of Location

As a first step of constructing a well, its location has to be evaluated. Proper siting of a well is crucial for its success and long-term sustainability. It is not only determined by physical factors (e.g. the prevailing geology, hydrology, proximity to the actual site of usage) but equally by ‘soft’ factors (e.g. acceptance by the community, capacities for O&M of the well including the pump, the type of water use, local habits, etc.). For this purpose several approaches exist ranging form simple to high-tech solutions. Villagers and members of the neighbouring communities can be a good source of information on the presence of shallow groundwater. Also, certain types of vegetation (e.g. banana plants, bulrushes, sugar cane, date palms) can indicate presence of groundwater (COLLINS 2000). Often, existing wells in close proximity indicate the presence of groundwater. If technical equipment is available, test borings can give detailed information on the groundwater level. For more detailed information see: CARTER et al. 2010.

Well Drilling Techniques

In order to access the groundwater, a hole has to be drilled and a permanent casing installed. The drilling must:

- Break or cut the formation,

- Remove the cut material from the hole, and, if necessary,

- Provide support to the walls of the hole, to prevent collapse during drilling (WAL 2010).

- Run pumping tests and develop the well.

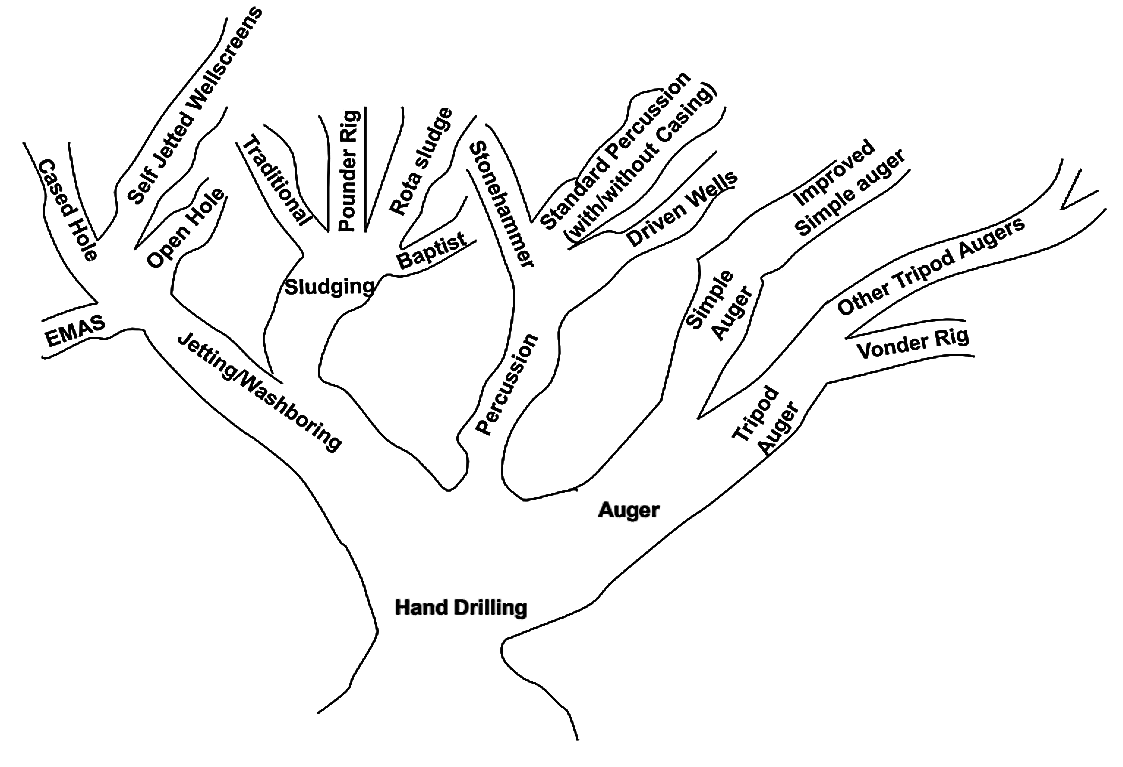

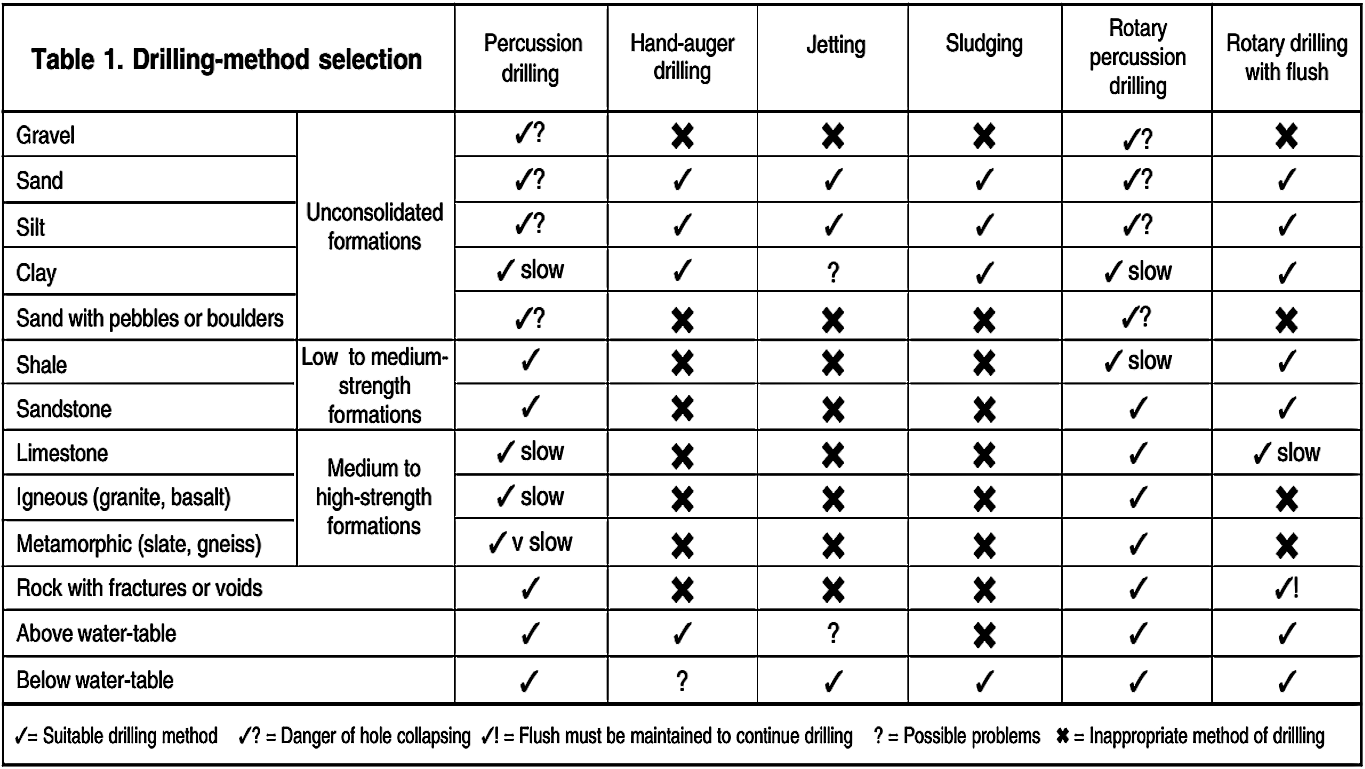

Therefore, a vast number of different techniques exist. Generally, four distinct types of manual drilling are distinguished: augering, percussion, sludging and jetting. (Cf. WAL 2010). Increasingly, more than one or two techniques are used in combination (DANERT 2009). Nevertheless, it is important to recognise that a well drilled to the same depth, in the same aquifer and properly developed will be equally productive regardless of the method of drilling (UNICEF 2010: Financing).

The choice of the optimal drilling technique mostly depends on geological and hydrological conditions but also on experience and endowments of local communities or drilling contractors.

Drilling Techniques in Detail

Adopted from WAL (2010)

1. Augering

The hand auger consists of extendable steel rods, rotated by a handle. A number of different steel augers (drill bits) can be attached at the end of the drill rods. The augers are rotated into the ground until they are filled, then lifted out of the borehole to be emptied.

Above the water table, the borehole generally stays open without the need for support. Below the water table a temporary casing may be used to prevent borehole collapsing.

Drilling continues inside the temporary casing using a bailer until the desired depth is reached. The permanent well casing is then installed and the temporary casing must be removed. Augers can be used up to a depth of about 15-25 meters, depending on the geology. Diameters range from 50 to 200mm.

| Advantage | Easy to use above groundwater table. Cheap equipment. |

| Disadvantage | It may be difficult to remove the temporary casing. |

| Geological application | Sand, silt & soft clay. |

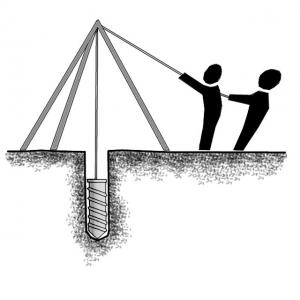

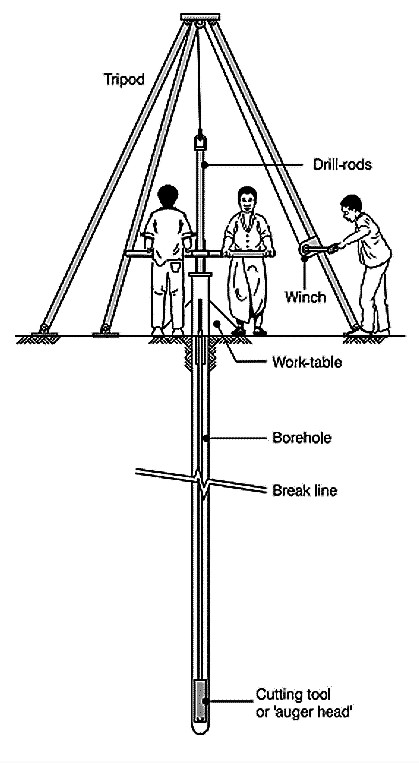

2. Percussion

Manual percussion uses a heavy cutting or hammering bit attached to a rope or cable and is lowered into the open bore hole or inside a temporary casing.

Usually, a tripod is used to support the tools. By moving the rope or cable up and down, the cutting or hammering bit loosens the soil or consolidated rock in the borehole, which is then extracted by using a bailer.

Just as with hand augering, a temporary casing of steel or plastic may be used to prevent the hole from collapsing.

When the permanent well screen and casing are installed, this temporary casing has to be removed. Manual percussion drilling is generally used up to depths of 25 meters.

| Advantage | Drills hard formations. |

| Disadvantage | The equipment can be heavy and expensive. The method is slow compared to others. |

| Geological application | Sand, silt, stiff clays, sandstone, laterite, gravel and small stones. |

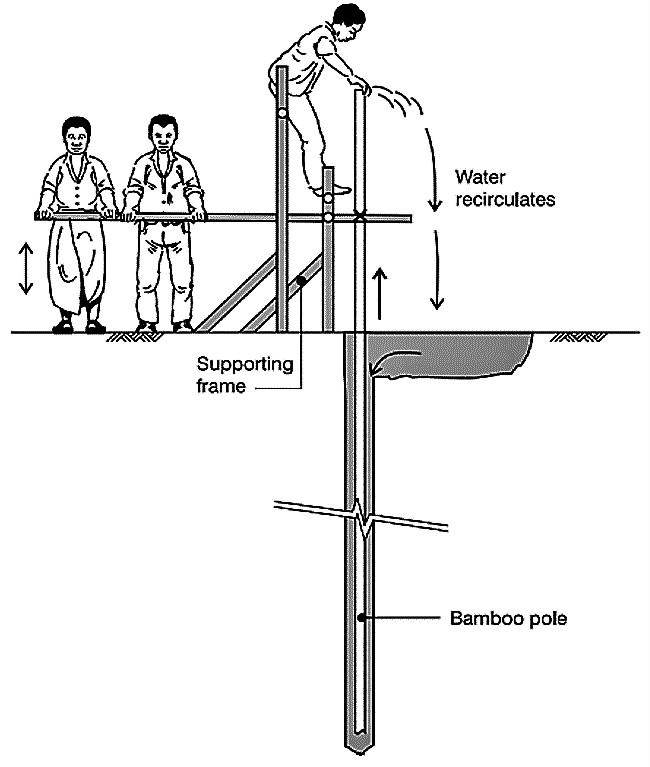

3. Sludging

Sludging uses water circulation to bring the drilled soil up to the surface. The drill pipes are moved up and down. On the down stroke, the impact of the drill bit loosens the soil and on the up stroke, the top of the pipe is closed by hand (or valve), drawing up the water through the pipe and transporting the cuttings to the surface.

On the next down stroke, the hand (valve) opens the top of the pipe and the water squirts into a pit, in front of the well. In this pit, the cuttings separate from the water and settle out, while the water overflows from the pit back into the well. The borehole stays open by water pressure.

Thickeners (additives) can be added to the water to prevent hole collapse and reduce loss of working water. Sludging can be used up to depths of about 35 meters.

| Advantage | Easy to use and temporary casing is not needed. |

| Disadvantage | Working water has to be maintained during the drilling process. The level of the water table is not known during drilling. |

| Geological application | Sand, silt, clay, stiff clay and softer- consolidated rock formations (weathered laterite). |

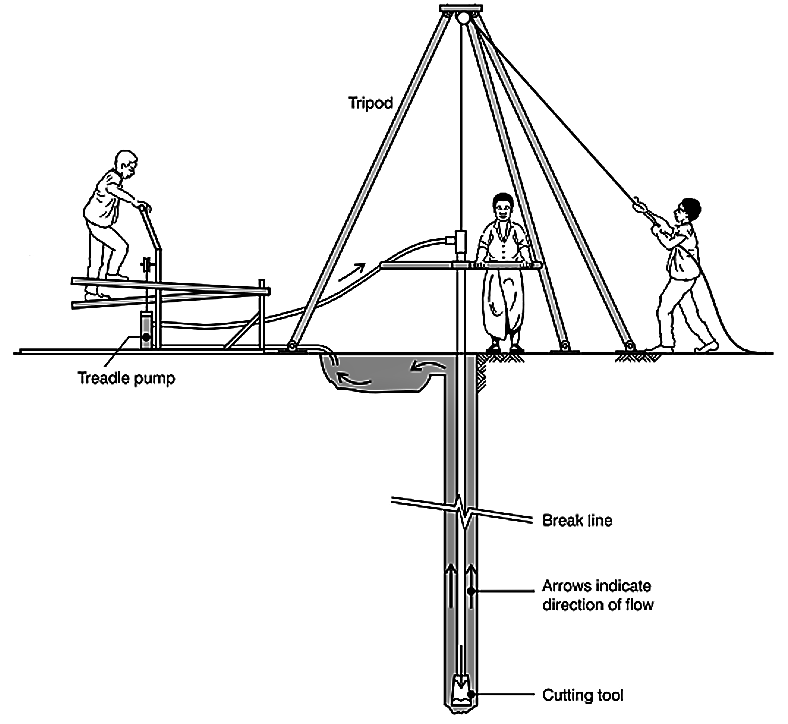

4. Jetting

Jetting is based on water circulation and water pressure. As opposed to sludging, water is pumped down the drilling pipes. The large volume of water has an erosive effect at the bottom and the ‘slurry’ (water and cuttings) are transported up between the drill pipe and the borehole wall.

A manual or motorised pump is used to achieve an adequate water flow.

The drill pipe may simply have an open end, or a drill bit can be added and partial or full rotation of the drill pipe can be used. Thickeners (additives) can be added to the water in order to prevent hole collapse and reduce loss of working water. Jetting (with rotation) is generally used up to depths of 35 meters.

| Advantage | Very quick in sand. |

| Disadvantage | A lot of working is needed at once. The level of the water table is not known during drilling. |

| Geological application | Limited to sand and thin layers of soft clay. |

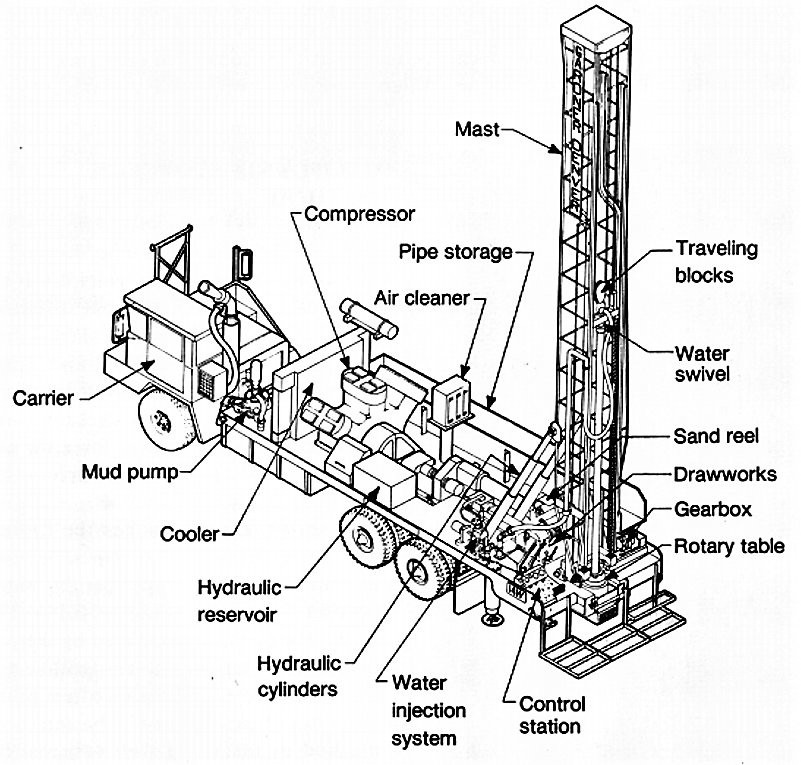

5. Mechanical Drilling

Drilling methods using machine-mounted rigs are essentially of two types, the percussion method or one of several rotary methods. Both methods have particular advantages, limitations, performance and suitability (WURZEL 2001). See WURZEL (2001) for detailed information.

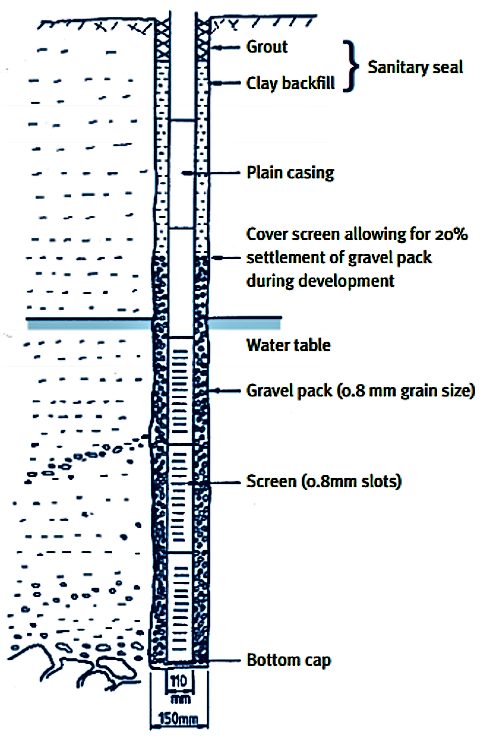

Completion of the Well

Having drilled the hole, several elements have to be installed before the well can be set into operation:

- The pump;

- The head works (apron) protects the opening at the surface from contaminants or particles entering the well;

- The sanitary seal is an impervious layer, preferably made out of concrete, preventing contamination of the well by holding back seepage through the gravel pack along the borehole;

- The well casing prevents the well from collapse and seepage of contaminants. Traditionally, steel pipes were used for lining but PVC pipe recently have replaced their use, as they are less expensive and easier to handle;

- The well screen holds back sediments while allowing water to infiltrate the well. The screen slots need to be smaller than the grain size of the surrounding soil. PVC pipes can easily be slit with special slitting saws to create thousands of fine cuts;

- The gravel pack, composed of graded gravel and sand, fills up the space between the screen and the borehole. It is only required if the surrounding soil has a grain size smaller than the slot size of the screen (WATERAID 2008; BALL 2001; WAL 2010).

Well Development and Testing

All drilling methods alter the hydraulic characteristics of formation materials in the vicinity of the borehole. Development procedures are designed to restore or improve these characteristics to maximise the performance (SMET & WIJK 2002). This is achieved by removing the fines and by consolidation of the gravel pack (WAL 2010). Over-pumping (that is, pumping at above the design-rate) can improve the efficiency of the packing by drawing further fine particles into it. Where the surrounding ground has many fine particles, the flow of water can be accelerated by back-flushing at a higher rate (WATERAID 2008) (see well rehabilitation).

Once a well has been developed and is free of any fines, the well should be test-pumped. Test pumping gives useful information about the performance of the well and indicates whether the well yield will be sufficient for its intended purpose (WAL 2010). It also indicates the maximum yield that can be drawn without risking overexploitation of the well. After having tested the water quality (see also water quality testing, the well can be set into operation.

Costs

Hand-drilled wells cost from US$ 20 to US$ 3,000, depending on the location, technology used, geology and hydrogeology. Given that conventionally drilled wells (i.e. mechanically drilled wells) in Sub-Saharan Africa can cost from US$ 2,000 to US$20,000, manual drilling, where feasible, could provide considerable savings for the provision of rural water supplies (DANERT 2009: HDD). Total costs mainly consist of costs for data, capital equipment, vehicles, fuel, materials, consumables and labour. A method to estimate well construction costs in your particular situation in more detail is provided by DANERT et al. (2010): Costing and Pricing.

Costs for operating and maintaining the drilled well are usually minor, unless well development or well rehabilitations become necessary due to an emergency, a contamination of the well or a reduction of the well yield. Operation and maintenance costs for manual pumping or mechanised pumping are generally dominant.

O&M

Operation of drilled wells comprises the pumping and cleaning of the surrounding area. Community members can easily operate a well on their own. Maintenance of a drilled well, however, includes maintaining the motor or electrical pump or manual pump as well, which needs more skills and experience. If the pump does not work, water abstraction is impossible. As for all groundwater sources, protection is vital to maintain water quality and hence an integral part of any maintenance plan.

Health Aspects

In general, drilled wells are less susceptible to contamination compared to dug wells. Still, particularly in areas with rapid development, the risk of introducing contaminants to the groundwater body via the hole itself is considerably high. The protection of the well, e.g. by installing an adequate sanitary seal (i.e. an apron) of suitable material between the permanent casing and the surrounding soil, is vital for a safe water supply in the long-term (SMET & WIJK 2002). Additional protection measures, such as a roof and a fence are easy to install but very effective in maintaining the water quality appropriate. If arsenic-bearing rock formations are present, dissolving processes can lead to natural contamination with arsenic when water is exposed to oxygen at the surface making arsenic removal technologies necessary.

| Working Principle | A hole is drilled into a groundwater body and infiltrating water is then abstracted with the help of a pump. |

| Capacity/Adequacy | Depending on the size (depth & diameter) and the hydrological conditions, drilled wells suit water supplies ranging from household use, small rural communities to urban areas with centralised supply systems. |

| Performance | Strongly depends on depth and diameter, the recharge capacity of the aquifer and the development of the well. |

| Costs | Rather low compared to machine-drilled wells. US$ 20 – 3000, depending on local conditions (DANERT 2009). |

| Self-help Compatibility | Experienced contractor needed for construction. Maintenance of the (necessary) pump needs trained repairers and equipment. |

| O&M | Simple operation. Although, maintenance of the (necessary) pump needs trained repairers and equipment. |

| Reliability | Very high if the well is not overused |

| Main strength | Fast construction, low susceptibility to contamination |

| Main weakness | Water-lifting device (i.e. pump) necessary |

Drilled wells can serve as water supply for single households, for small rural communities and for more urban areas, depending on the size of the well (depth & diameter) and the hydrological conditions. Manual (hand) drilling is a practical and low-cost solution for wells less than 40 meters deep in alluvial soils or soft rock formations (UNICEF 2010). Various simple manual drilling techniques are available suiting most geological conditions. Nevertheless, experienced drilling teams and some equipment is needed for construction.

It should be kept in mind that with the construction water provision is not guaranteed yet, as water still needs to be lifted out of the ground with the help of a manual or motorised pump and distributed. Proper maintenance of these devices has to be guaranteed (DANERT 2009).

Drilled wells are less susceptible to contamination of groundwater compared to dug wells. But still, well protection is vital to optimise your local water management system in the long-term. If abstraction is not overused, no major effects on the environment are to be expected. However, special attention has to be paid to abstraction rates if the well is located in coastal areas as saltwater might intrude the well if the draft is too high.

Drilled Wells

This manual explains in practical terms the basic drilling techniques. It describes the use of fluid circulation in soft ground formations, and com- pressed air and hammers for hard rock. It discusses well design, types of pump and their installation, screen selection, and testing.

BALL, P. (2001): Drilled Wells. (= Series of Manuals on Drinking Water Supply , 6 ). St. Gallen: Swiss Centre for Development Cooperation in Technology and Management (SKAT) URL [Accessed: 11.03.2019] PDFSiting of Drilled Water Wells

This field note has been written for managers of water supply programmes and projects. It provides a step-by-step guide on the siting of drilled water wells. As a first step, the essential requirements for a simple groundwater model are set out, including some basic explanations to help the reader establish a sound understanding of hydrogeology.

CARTER, R. CHILTON, J. DANERT, K. OLSCHEWSKI, A. (2010): Siting of Drilled Water Wells. A Guide for Project Managers. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFHand-dug Shallow Wells

This highly recommended publication comprises everything regarding the establishment of a water supply system based on (shallow) hand-dug wells for communities in the South. It elaborates on the underlying hydrogeological principles, preparatory investigations, design, construction, operation and maintenance, and it discusses the most common mistakes made in design and construction.

COLLINS, S. (2000): Hand-dug Shallow Wells. (= Series of Manuals on Drinking Water Supply , 5 ). St. Gallen: Swiss Centre for Development Cooperation in Technology and Management (SKAT) URL [Accessed: 08.03.2019] PDFHand Drilling Directory

This document provides a short summary of each of the hand drilling techniques being utilised today; a country-by-country overview of the extent of hand drilling taking place in select countries; an annotated list of organisations involved in promoting and supporting hand drilling and an extensive list of literature, from published articles to training materials and online videos.

DANERT, K. (2009): Hand Drilling Directory. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFCode of Practice for Cost Effective Boreholes

The Code of Practice sets out nine principles that relate directly to the practicalities of borehole construction. They should be adhered to in order to provide cost-effective boreholes.

DANERT, K. ARMSTRONG, T. ADEKILE, D. DUFFAU, B. OUEDRAOGO, I. KWEI, C. (2010): Code of Practice for Cost Effective Boreholes. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFCosting and Pricing. A Guide for Water Well Drilling Enterprises

This field note is written for water well drilling enterprises as well as other agencies, which manage, or are involved in drilling projects. Using a step-by-step approach it gives clear guidance on how to cost and price the construction of drilled water wells. It also provides tips on business management with an emphasis of the realities faced in many countries in Sub-Saharan Africa.

DANERT, K. LUUTU, A. CARTER, R. OLSCHWESKI, A. (2010): Costing and Pricing. A Guide for Water Well Drilling Enterprises. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFHand drilling (percussion drilling) in Niger

Small Community Water Supplies: Technology, People and Partnership: Groundwater Withdrawal - Chapter 10

This book provides a general introduction to a wide range of technologies. Among the topics covered are: planning and management of small water supplies, community water supplies in Central and Eastern European countries, water quality and quantity, integrated water resources management, artificial recharge, rainwater harvesting, spring water tapping, groundwater withdrawal, water lifting, surface water intake, water treatment, aeration, coagulation and flocculation, sedimentation, multi-stage filtration, desalination technology, disinfection, household level water treatment, technologies for arsenic and iron removal from ground water, and emergency and disaster water supply. Chapter 10: Groundwater Withdrawal

SMET, J. ; WIJK, C. van (2002): Small Community Water Supplies: Technology, People and Partnership: Groundwater Withdrawal - Chapter 10. The Hague: International Water and Sanitation Centre (IRC) URL [Accessed: 08.03.2019] PDFFinancing Options for Low-cost Well Drillers & Communities for Rural Water Supply

The purpose of this manual is to provide straightforward financing guidance to “low cost well drilling enterprises” involved in water well drilling operations, as well as to village and community groups, individual, and NGOs (“community customers”) intending to borrow the necessary capital to hire services from such well drilling enterprises.

UNICEF (2010): Financing Options for Low-cost Well Drillers & Communities for Rural Water Supply. New York: UNICEF URL [Accessed: 21.03.2012] PDFUnderstanding Groundwater & Wells in Manual Drilling. Instruction Handbook for Manual Drilling Teams on Hydro-geology for Well Drilling, Well Installation and Well Development

The manual ‘Understanding Groundwater & Wells in manual drilling’ complements the 4 technical training handbooks and highlights those essential subjects which are relevant to manual drilling, geo-hydrology, hygiene, well installation and well development in practice, in simple and understandable language.

WAL, A. van der (2010): Understanding Groundwater & Wells in Manual Drilling. Instruction Handbook for Manual Drilling Teams on Hydro-geology for Well Drilling, Well Installation and Well Development. Papendrecht: PRACTICA Foundation URL [Accessed: 21.03.2012] PDFTechnology Notes

These technology notes have been prepared following many general enquiries for technical information having been received by WaterAid over the years. Their purpose is to give an outline of the technologies used by WaterAid on long-term development projects in Africa and Asia, and to show alternatives, which might be appropriate in different circumstances. It may be possible to determine from the notes the technology, which would be appropriate in a particular location.

WATERAID (2008): Technology Notes. London: WaterAid URL [Accessed: 04.01.2011] PDFDrilling Boreholes for Handpumps

This booklet seeks to suggest ways in which funds can be better used for making safe water available to the poor by illustrating how drilling costs can be reduced without compromising water quality, water quantity, or the productive life of the borehole.

WURZEL, P. (2001): Drilling Boreholes for Handpumps. (= Working Papers on Water Supply and Environmental Sanitation , 2 ). St. Gallen: Swiss Centre for Development Cooperation in Technology and Management (SKAT) URL [Accessed: 11.03.2019] PDFDrilled Wells

This manual explains in practical terms the basic drilling techniques. It describes the use of fluid circulation in soft ground formations, and com- pressed air and hammers for hard rock. It discusses well design, types of pump and their installation, screen selection, and testing.

BALL, P. (2001): Drilled Wells. (= Series of Manuals on Drinking Water Supply , 6 ). St. Gallen: Swiss Centre for Development Cooperation in Technology and Management (SKAT) URL [Accessed: 11.03.2019] PDFSiting of Drilled Water Wells

This field note has been written for managers of water supply programmes and projects. It provides a step-by-step guide on the siting of drilled water wells. As a first step, the essential requirements for a simple groundwater model are set out, including some basic explanations to help the reader establish a sound understanding of hydrogeology.

CARTER, R. CHILTON, J. DANERT, K. OLSCHEWSKI, A. (2010): Siting of Drilled Water Wells. A Guide for Project Managers. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFHand Drilling Directory

This document provides a short summary of each of the hand drilling techniques being utilised today; a country-by-country overview of the extent of hand drilling taking place in select countries; an annotated list of organisations involved in promoting and supporting hand drilling and an extensive list of literature, from published articles to training materials and online videos.

DANERT, K. (2009): Hand Drilling Directory. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFCode of Practice for Cost Effective Boreholes

The Code of Practice sets out nine principles that relate directly to the practicalities of borehole construction. They should be adhered to in order to provide cost-effective boreholes.

DANERT, K. ARMSTRONG, T. ADEKILE, D. DUFFAU, B. OUEDRAOGO, I. KWEI, C. (2010): Code of Practice for Cost Effective Boreholes. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFCosting and Pricing. A Guide for Water Well Drilling Enterprises

This field note is written for water well drilling enterprises as well as other agencies, which manage, or are involved in drilling projects. Using a step-by-step approach it gives clear guidance on how to cost and price the construction of drilled water wells. It also provides tips on business management with an emphasis of the realities faced in many countries in Sub-Saharan Africa.

DANERT, K. LUUTU, A. CARTER, R. OLSCHWESKI, A. (2010): Costing and Pricing. A Guide for Water Well Drilling Enterprises. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFSmall Community Water Supplies: Technology, People and Partnership: Groundwater Withdrawal - Chapter 10

This book provides a general introduction to a wide range of technologies. Among the topics covered are: planning and management of small water supplies, community water supplies in Central and Eastern European countries, water quality and quantity, integrated water resources management, artificial recharge, rainwater harvesting, spring water tapping, groundwater withdrawal, water lifting, surface water intake, water treatment, aeration, coagulation and flocculation, sedimentation, multi-stage filtration, desalination technology, disinfection, household level water treatment, technologies for arsenic and iron removal from ground water, and emergency and disaster water supply. Chapter 10: Groundwater Withdrawal

SMET, J. ; WIJK, C. van (2002): Small Community Water Supplies: Technology, People and Partnership: Groundwater Withdrawal - Chapter 10. The Hague: International Water and Sanitation Centre (IRC) URL [Accessed: 08.03.2019] PDFFinancing Options for Low-cost Well Drillers & Communities for Rural Water Supply

The purpose of this manual is to provide straightforward financing guidance to “low cost well drilling enterprises” involved in water well drilling operations, as well as to village and community groups, individual, and NGOs (“community customers”) intending to borrow the necessary capital to hire services from such well drilling enterprises.

UNICEF (2010): Financing Options for Low-cost Well Drillers & Communities for Rural Water Supply. New York: UNICEF URL [Accessed: 21.03.2012] PDFImproving Skills of Manual Drilling Enterprises. Business Management

This manual has been devised as a training guide for small businesses specialised in manual drilling and related businesses such as those specialising in pump making and pump repair.

UNICEF (2010): Improving Skills of Manual Drilling Enterprises. Business Management. New York: UNICEF URL [Accessed: 21.03.2012] PDFProfessionalizing the Manual Drilling Sector in Africa. A Guide to Building Capacity to Increase Access to Safe Water in Rural Areas

The purpose of this manual is to assist UNICEF Country Offices and others interested in promoting the emergence of a professional manual drilling sector in their country of operation. The manual provides a step-by step methodology, based on experiences in Niger, Chad and Senegal, for the promotion of a local professional manual drilling sector.

UNICEF (2010): Professionalizing the Manual Drilling Sector in Africa. A Guide to Building Capacity to Increase Access to Safe Water in Rural Areas. New York: UNICEF URL [Accessed: 21.03.2012] PDFUnderstanding Groundwater & Wells in Manual Drilling. Instruction Handbook for Manual Drilling Teams on Hydro-geology for Well Drilling, Well Installation and Well Development

The manual ‘Understanding Groundwater & Wells in manual drilling’ complements the 4 technical training handbooks and highlights those essential subjects which are relevant to manual drilling, geo-hydrology, hygiene, well installation and well development in practice, in simple and understandable language.

WAL, A. van der (2010): Understanding Groundwater & Wells in Manual Drilling. Instruction Handbook for Manual Drilling Teams on Hydro-geology for Well Drilling, Well Installation and Well Development. Papendrecht: PRACTICA Foundation URL [Accessed: 21.03.2012] PDFDrilling Boreholes for Handpumps

This booklet seeks to suggest ways in which funds can be better used for making safe water available to the poor by illustrating how drilling costs can be reduced without compromising water quality, water quantity, or the productive life of the borehole.

WURZEL, P. (2001): Drilling Boreholes for Handpumps. (= Working Papers on Water Supply and Environmental Sanitation , 2 ). St. Gallen: Swiss Centre for Development Cooperation in Technology and Management (SKAT) URL [Accessed: 11.03.2019] PDFCleaning and Rehabilitating Boreholes

This technical note sets out the actions required to repair and rehabilitate a borehole after any disaster.

GODFREY, S. REED, B. (2013): Cleaning and Rehabilitating Boreholes. (= Technical Notes on Drinking-Water, Sanitation and Hygiene in Emergencies , 2 ). Geneva: World Health Organization (WHO) URL [Accessed: 26.08.2013] PDFThe Drilling Environment and Establishing a Drillers Association in Nigeria. Summary Report

RWSN, with support of the Water and Sanitation Programme of the World Bank (WSP-AF) is supporting the formation of a Nigerian Drillers Association. This report provides an overview of the Nigerian drilling environment and sets out the first stage of the process of establishing the association.

ADEKILE, D. (2007): The Drilling Environment and Establishing a Drillers Association in Nigeria. Summary Report. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFRationalization of Drilling Operations in Tanzania. Review of the Borehole Drilling Sector in Tanzania

This study reviews the situation in the drilling sector in Tanzania, assesses options, and identifies support areas.

BAUMANN, E. BALL, P. BEYENE, A. (2005): Rationalization of Drilling Operations in Tanzania. Review of the Borehole Drilling Sector in Tanzania. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFTen-step Guide Towards Cost-effective Boreholes. Case Study of drilling costs in Ethiopia

Increasing access to groundwater is a high priority in Sub-Saharan Africa. One key to this is to reduce the costs of conventional drilling and borehole construction. This field note, describing a recent study in Ethiopia, sets out how this may be done.

CARTER, R. (2006): Ten-step Guide Towards Cost-effective Boreholes. Case Study of drilling costs in Ethiopia. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFA Brief History of Hand Drilled Wells in Niger. Only the Beginning

This field note describes the history of hand drilling and water-lifting techniques introduced in Niger over 30 years ago and now firmly in the hands of local enterprises, farmers and household water users. Recommendations for the way forward are included.

DANERT, K. (2006): A Brief History of Hand Drilled Wells in Niger. Only the Beginning. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 21.03.2012] PDFBurkina Faso: Summary of Findings of 2009 Study and Draft National Code of Conduct. Code of Practice for Cost-Effective Boreholes

This report provides a summary of the study on how to optimise the costs of boreholes construction in Zambia, Ghana and Burkina Faso.

DUFFAU, B. OUEDRAOGO, I. (2009): Burkina Faso: Summary of Findings of 2009 Study and Draft National Code of Conduct. Code of Practice for Cost-Effective Boreholes. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFThe Impact of Manual drilling for the Construction of Sustainable Water-Points in Chad. Case Study

This case study examines the impact of professional manual drilling operations on the problem of increasing the rate of delivery of improved water supply in Chad.

UNICEF (2009): The Impact of Manual drilling for the Construction of Sustainable Water-Points in Chad. Case Study. New York: UNICEF URL [Accessed: 21.03.2012] PDFImproving Cost Effectiveness of Drilling Programmes in Mozambique and Zambia

The Rural Water Supply Network (RWSN), in collaboration with UNICEF, recently published a Code of Practice for Cost Effective Boreholes. This document outlines principles that provide a basis for the realisation of economical and sustainable access to safe water through the construction of boreholes in Sub-Saharan Africa. Evaluation of these principles in specific countries underlined the importance of improved contractual procedures and technical specifications for significant reductions in drilling costs.

UNICEF (2011): Improving Cost Effectiveness of Drilling Programmes in Mozambique and Zambia. New York: UNICEF PDFSelf-Supply as a Complementary Water Services Delivery Model in Ethiopia

Self-supply, where households invest to develop their own easily-accessible water supplies, is identified as an alternative service delivery model that is potentially complementary to more highly subsidised community-level provision. The approach is widespread in Ethiopia with family wells bringing additional benefits that are in line with wider government objectives, such as supporting small-scale irrigation. However, two recent studies show the current performance of traditional or family wells to be far below potential with most sources providing unsafe water in the absence of adequate protection.

BUTTERWORTH, J. ; SUTTON, S. ; MEKONTA, L. (2013): Self-Supply as a Complementary Water Services Delivery Model in Ethiopia. In: Water Alternatives: Volume 6 , 405-423. URL [Accessed: 08.03.2019] PDFCode of Practice for Cost Effective Boreholes

The Code of Practice sets out nine principles that relate directly to the practicalities of borehole construction. They should be adhered to in order to provide cost-effective boreholes.

DANERT, K. ARMSTRONG, T. ADEKILE, D. DUFFAU, B. OUEDRAOGO, I. KWEI, C. (2010): Code of Practice for Cost Effective Boreholes. St. Gallen: Rural Water Supply Network (RWSN) URL [Accessed: 11.03.2019] PDFTechnical Review. Borehole Drilling and Rehabilitation under Field Conditions

This technical review presents and synthesises an impressive amount of practical experience in the field of borehole drilling and rehabilitation.

ICRC (2010): Technical Review. Borehole Drilling and Rehabilitation under Field Conditions. Geneva: International Committee of the Red Cross (ICRC) URL [Accessed: 21.03.2012] PDFTechnical Review. Practical Guidelines for Test Pumping in Water Wells

The practical guidelines for test pumping presented in this publication reflect years of hands-on experience in borehole exploitation in both rural and urban settings, from Africa to the Middle East and Asia.

ICRC (2011): Technical Review. Practical Guidelines for Test Pumping in Water Wells. Geneva: International Committee of the Red Cross (ICRC) URL [Accessed: 21.03.2012] PDFManual Drilling Series: Augering. Technical Training Handbook on Affordable Manual Well Drilling

This handbook describes the hand auger technique. This cheap and effective technique is very suitable for sinking shallow wells in soft soils and is excellent for soil surveys. Many drilling teams have this technique in their toolkit to complement other drilling techniques.

LABAS, J. VUIK, R. (2010): Manual Drilling Series: Augering. Technical Training Handbook on Affordable Manual Well Drilling. Papendrecht: PRACTICA Foundation URL [Accessed: 21.03.2012]Manual Drilling Series: Jetting. Technical Training Handbook on Affordable Manual Well Drilling

This handbook describes the various jetting techniques in detail that can be used to drill wells in loose and soft soil formations. With this technique, wells are drilled in a few hours rather than days.

VUIK, R. (2010): Manual Drilling Series: Jetting. Technical Training Handbook on Affordable Manual Well Drilling. Papendrecht: PRACTICA Foundation URL [Accessed: 21.03.2012] PDFManual Drilling Series: Percussion. Technical Training Handbook on Affordable Manual Well Drilling

This handbook describes the percussion technique in detail. Although the technique is slower than other drilling techniques, it is the only manual drilling technique that is able to drill through consolidated rock layers.

VUIK, R. KONING, D. de WAL, A. van der (2010): Manual Drilling Series: Percussion. Technical Training Handbook on Affordable Manual Well Drilling. Papendrecht: PRACTICA Foundation URL [Accessed: 21.03.2012] PDFDrainage from Water Points

This poster is part of the series of Water, Sanitation and Hygiene posters designed by the Water, Engineering and Development Center of Loughborough University.

SKINNER, B.H. CHATTERTON, K. SHAW, R. (2013): Drainage from Water Points. Poster. (= WEDC Posters , 7 ). London: Water, Engineering and Development Center (WEDC) URL [Accessed: 28.08.2013] PDFA Water Handbook

The Water Handbook is the result of wide collaboration within UNICEF. It provides a broad overview of state-of-the-art programming for water management, protection and supply.

UNICEF (1999): A Water Handbook. (= Water, Environment and Sanitation Technical Guidelines , 2 ). New York: United Nations Children’s Fund (UNICEF) URL [Accessed: 08.03.2019] PDFManual Drilling

The Rural Water Supply Network is a global knowledge network for rural water supply technologies and approaches. The website provides many excellent publications on various topics on rural development, particularly on hand drilled wells. This section presents an overview of the scale and type of hand drilling activity being undertaken in selected countries and the organisations involved.

Technical Note Series on Manual Drilling

UNICEF, Practica and Enterprise Works/VITA have developed a toolkit for African countries aiming to embark on the professionalisation of manual drilling. This comprehensive toolkit includes technical notes, technical manuals, advocacy materials, mapping of suitable areas for manual drilling, case studies, and implementation and training manuals.

European Soil Data Centre (ESDAC)

The choice of drilling technique and well type crucially depends on local geology. This website provides detailed soil maps of Africa and Asia, among others.