Executive Summary

Large-scale anaerobic biogas digesters are reactors used for the conversion of the organic fraction of large volumes of slurries and sludge into biogas by anaerobic digestion. Biogas is recovered and used either directly for heating the reactors or transformed into combined power and heat and fed into the grid. It can also be upgraded to natural gas quality. Typical substrates are excess sludge from wastewater treatment plants or waste slurries from agriculture (manure) or (diary) industry. Energy crops may also be added in order to increase the gas yield. Large-scale anaerobic digesters have been mainly developed in industrialised countries and many different designs and types are available - most of them are rather high-tech and require expert construction, operation and maintenance skills. Biogas is a green energy and has the potential to reduce greenhouse gas emission. Due to increasing fuel prices and climate change, biogas generation from wastes and energy corps at large-scale is gaining interest also in developing countries.

| In | Out |

|---|---|

Blackwater, Faecal Sludge, Brownwater, Faeces, Excreta, Organic Solid Waste |

Biogas, Compost/Biosolids |

Introduction

Large-scale biogas reactors are designed for the conversion of the organic fraction of large volumes of slurries and sludge into biogas. Typical substrates are excess sludge from large-scale wastewater treatment plants, agricultural and food industry wastes (e.g. manure, from stock framing, sugar refining, starch production, coffee processing, alcohol generation, slaughterhouses etc.) or industrial wastes (e.g. from paper manufacturing, biotechnological industries, etc.) (WERNER et al. 1989).

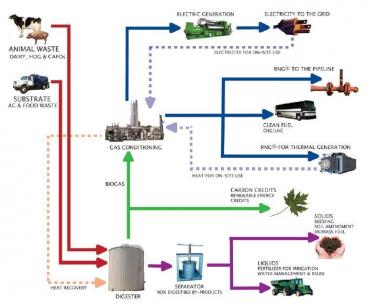

Biogas production form agriculture and food industry waste slurry. Products are electricity, clean fuel, carbon credits and liquid and solid fertiliser. Source: BIOPACT (n.y.)

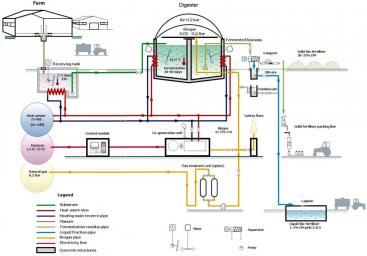

Energy crops are sometimes also added in order to increase biogas yields. The produced biogas can be recovered and generally transformed into heat in a gas turbine or into combined heat and power (CHP) in cogeneration plants and fed into the public grid (MES et al. 2003; JENSSEN et al. 2004; WRAPAI 2009) (see also conversion of biogas to electricity at large scale). It can also be upgraded to natural gas quality, compressed and used to power motor vehicles. The sludge that remains after digestion is rich in nutrients and can be used as a soil amendment in agriculture, generally after anaerobic composting as final treatment step.

The generation of combined heat and power as well as natural gas from agricultural products. Overall scheme. Source: UNKNOWN (n.y.)

To date, such large-scale biogas digesters have been mainly applied and developed in industrialised countries resulting in plants with sophisticated equipment and operational techniques (e.g. wet and dry digestion processes, heated and unheated reactors, batch and continuous reactors etc.). They vary in design and complexity but have all in common to require expert planning, design and staff for operation and maintenance. Given increasing electricity and fuel prices, the dissemination of large-scale biogas plants also gains in interest in less industrialised countries (BRUYN 2006).

Treatment Process and Design Principals

A typical egg-shaped biogas reactor in Germany (left) and an agricultural fixed-dome biogas reactor. Sources: MIKLED (n.y.) and KLIMA SUCHT SCHUTZ (n.y.)

Vertical continuously stirred tank reactor (CSTR, left) and horizontal plug-flow reactor (PFR, right) — two examples for large-scale agricultural biogas digesters in Europe. Source: BRUYN (2006)

As small-scale digesters (see also biogas digester small scale), large-scale anaerobic digesters treating slurries are generally designed according to the wet digestion process with 10 to 20 % of total solids (TS) (see also anaerobic treatment of waste and wastewater). The volumes of the reactors are ranging from several hundred to several thousand m3. Due to the size of plant, the respective objectives and special requirements concerning operation and substrates, the anaerobic treatment of waste materials and wastewater at large-scale requires a different set of planning mechanisms, plant types and implementation factors (WERNER et al. 1989). The designer must know that he cannot ‘simply’ enlarge the plants for a small-scale plant to any degree (SASSE 1988). When a low-tech solution is required, it is possible to construct several low-tech small and decentralised biogas plants instead of one single larger digester in order to facilitate operation and maintenance (ICRC 2009).

The most common forms of large-scale digesters are batch reactors and continuous-flow, plug-flow and continuously stirred tank reactor (PFR and CSTR). Fed-batch reactors (accumulation systems) are sometimes also applied (MES et al. 2003). Completely mixed and batch systems are generally built vertically, plug-flow reactors are generally horizontal reactors. Horizontal reactors are often constructed similar to floating or expandable plastic dome plants (see biogas digester small scale) but much larger. Fixed dome are also used, but require large volumes of retention tanks for sludge expansion.

Sustainable sanitation concept (energy recovery and nutrient recycling) of the city of Braunschweig, Germany: The wastewater treatment plants covers its energy needs with the production of biogas from excess sludge combined with biogas recovered from landfills and green waste digestion. Agricultural plants, digesting energy crops (corn) produce biogas, which is transformed to combined heat and power which is fed into the grid of Braunschweig. Source: VEOLIA WATER (2010)

The anaerobic digestion is either carried out in the mesophilic (20 to 35 °C) or the thermophilic range (50 to 60 °C). Thermophilic processes produce more biogas in shorter time. However, mesophilic processes are often preferred as high temperatures require higher input energy to obtain operation temperatures and the production of ammonia, which is toxic for the anaerobic microorganism producing the biogas, is higher at higher temperatures (ISAT & GTZ 1999) (see also anaerobic treatment of waste and wastewater).

One way to optimise large-scale anaerobic digesters is to use multi-stage digestion, which allows to more accurately control pH and temperature, the main process factors influencing the performance of the digestion bacteria. In such systems, the four stages of anaerobic digestion (hydrolysis and acidogenesis from acetogenesis and methanogenesis) are separated in different consecutive compartments (MES et al. 2003). Consequently, the optimum conditions for each type of bacteria must be maintained in a smaller volume (e.g. high temperatures for methanogenesis), resulting in a simplified maintenance and in energy savings.

Example of Application: Anaerobic Digestion of Excess Sludge from Lager-Scale Wastewater Treatment Plants

Sewage or municipal wastewater can be treated by anaerobic digestion, but due to the liquid nature of such wastes, the process requires high-rate anaerobic digestion reactors (e.g. upflow anaerobic sludge blanket reactors).

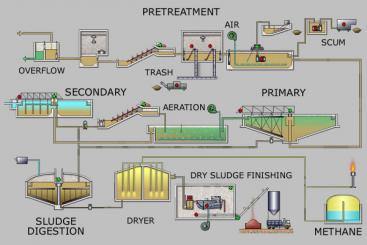

However, when sewage is treated in a conventional large-scale wastewater treatment plant (e.g. in an activated sludge system, see factsheet activated sludge), the anaerobic treatment of the excess sludge is often integrated into the overall process (TBW 2001). In activated sludge systems, sludge means the total solid material that results from sedimentation and bacterial activity and growth during the aerobic wastewater treatment. During the process, much of the sludge is recirculated (see picture below), while the excess sludge is treated together with the sludge from primary sedimentation in an anaerobic digester.

Overall scheme of a high-tech activated sludge wastewater treatment plant combined with sludge digestion and biogas production. Source: WIKIPEDIA (2010)

Typical excess sludge digesters work often in mesophilic, sometimes thermophilic conditions. The sludge retention time is about one month (TBW 2001). To generate appropriate reactor temperatures, a heating system is required. The biogas plant’s energy requirements for heating and other uses can partly, sometimes fully, be covered by utilising the produced gas (transformation in a CHP). Excess heat and power is fed in the local heat and power grid. The excess gas can also be compressed and sold as natural gas (e.g. for vehicles).

The remaining sludge is post-treated most often by aerobic composting. In Central Europe, where the digestion of excess sludge from wastewater treatment plant is common (TBW 2001), the use of the remaining sludge in agriculture is often restricted due to the risk of over-fertilisation (eutrophication) and the high content of heavy metals and other pollutants which can be introduced into the soil and water by applying the sludge on the fields. Therefore, the remaining slurry is generally dewatered and disposed of in landfills or incinerators. To recover the nutrients contained in the remaining sludge (mainly P and N but also some other trace minerals) high-tech solutions (e.g. ASH DEC) are being developed and more and more frequently used (see also advanced nutrient recovery). Though this process serves the purpose of recycling, it is highly energy and cost intensive and requires high-tech solutions.

At a Glance

| Working Principle | High-strength slurries from wastewater treatment plants, agriculture or industry are fed in an airtight reactor where the organic fraction is transformed into biogas by anaerobic digestion. Biogas is transformed into heat and power and used as green energy source. The remaining sludge is rich in nutrients and could be used in agriculture. |

| Capacity/Adequacy | Large-scale anaerobic digesters are complex in design, planning and operation and are therefore only adapted at a large scale, involving the collaboration of various experts. |

| Performance | High volume reduction of wastes; Relatively high pathogen removal; Nutrients remain in the sludge; SRT of some weeks |

| Costs | High capital costs, high operation costs. |

| Self-help Compatibility | High-tech expert design is required. |

| O&M | Operation and maintenance requires a strict organisation and the continuous involvement of experts. |

| Reliability | Resistant to shock loading. Reliable if operated and maintained well. |

| Main strength | High volume reduction of municipal, agricultural and industrial wastes; Generation of green energy; Potential for greenhouse gas reduction. |

| Main weakness | Expert design is required; high-tech and cost intensive. |

Large-scale anaerobic digesters are designed for the treatment of large-volumes of high-strength waste slurries form agriculture and industry (e.g. manure, slaughterhouses, paper manufacturing) or to treat the excess sludge from large-scale wastewater treatment plants (activated sludge systems). The different plants vary strongly in design and complexities, but all require expert planning, design and staff for operation and maintenance.

They are either fed-batch, batch, or continuous reactors, which are run within the mesophilic range. The operation temperature is normally achieved by heating. Generated biogas often gives enough power and heat to run the plant. Excess power (and heat) is fed into the public grid if possible.

In Europe, energy crops (e.g. maize and grass) are sometimes fed into the reactors to enhance biogas yields. However, the cultivation of energy-rich plants specifically for the production of bio-fuels is often not sustainable, due to the high inputs (water, nutrients, land); furthermore, their production competes with the production of food crops.

Dairy Waste Anaerobic Digestion Handbook. Options for Recovering Beneficial Products from Dairy Manure

This manual provides an introduction to the anaerobic digestion of dairy manure. The operation and waste management practices of Idaho dairies, the anaerobic digestion and the anaerobic digestion processes suitable for dairy waste, the typical design applications for different types of dairies and finally the cost and benefits of the facilities are discussed.

BURKE, P.E. Dennis, A. (2001): Dairy Waste Anaerobic Digestion Handbook. Options for Recovering Beneficial Products from Dairy Manure. Olympia: Environmental Energy CompanyOntario Large Herd Operators European Anaerobic Digestion Tour Report

Biogas Technology - A Training Manual for Extension

This manual contains a complete set of training materials on various topics around the large-scale dissemination of domestic (agricultural) biogas systems, including a system approach to biogas technology, biogas programmes, reuse of slurry, subsidy and institutional financing, quality standards and monitoring and evaluation issues.

FAO (1996): Biogas Technology - A Training Manual for Extension. Support for Development of National Biogas Programme (FAO/TCP/NEP/4451-T) . Consolidated Management Services Nepal (P) Ltd. and Food and Agriculture Organization of the United Nations (FAO) URL [Accessed: 19.04.2010]Technology Review of Biogas Sanitation

This document provides an overview and introduction on biogas sanitation (anaerobic digestion) for blackwater or for brown water, or excreta treatment for reuse in developing countries. The main technologies discussed are biogas settlers (BSs), biogas septic tanks, anaerobic baffled reactor (ABRs), anaerobic filter (AFs) and upflow anaerobic sludge blanket reactors (UASBs).

MANG, H.-P. LI, Z. (2010): Technology Review of Biogas Sanitation. (= Technology Review ). Eschborn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 26.05.2019]Evaluation of Biogas Sanitation Systems in Nepalese Prisons

Biogas Basics

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume I tells you all you need to get an overview on biogas sanitation systems, from history over process and operation parameters to social, political and cultural issues.

ISAT ; GTZ (1999): Biogas Basics. (= Biogas Digest , 1 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ) URL [Accessed: 03.06.2019]Sustainable Wastewater Management in Urban Areas

A document about sustainable wastewater management in urban areas.

JENSSEN, P.D. GREATOREX, J.M. WARNER, W. S. (2004): Sustainable Wastewater Management in Urban Areas. (= Kapitel 4. Kurs WH33, Konzeptionen dezentralisierter Abwasserreinigung und Stoffstrommanagement ). Hannover: University of HannoverDevelopment of biogas technology for livestock farms in Thailand

Anaerobic Digestion of Biodegradable Solid Waste in Low- and Middle-Income Countries

Biogas Plants

This rather old document still gives a good overview on biogas technology. It is intended to help designers of a biogas plant to be able to distinguish between valid and invalid solutions.

SASSE, L. (1988): Biogas Plants. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbH URL [Accessed: 15.05.2012]Anaerobic Methods of Municipal Wastewater Treatment

Technical information on the advantages and main technologies of anaerobic digestion treatment for wastewaters in developing countries.

GATE (2001): Anaerobic Methods of Municipal Wastewater Treatment. Technical Information W3e. Frankfurt (Germany): GATE Information Service and Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH URL [Accessed: 03.06.2019]Biogas Plants in Animal Husbandry

This guide addresses the planners and providers of stock-farming and agricultural-extension services in developing countries. It is intended to serve as a source of information on the potentials of and prerequisites for biogas technology: a decision-making and planning aid for the construction and dissemination of biogas plants: a book of reference for information on practical experience and detailed data.

WERNER, U. STOEHR, U. HEES., N. (1989): Biogas Plants in Animal Husbandry. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbHDocument 8, Data Management Document, Appendix S 06 - Energy Research

This document provided by Waste Refinery Australia Project Association Inc. contains information on biogas, different types of cogeneration (CHP) and district heating. Additionally there are also facts and information on hydronics and gas flare.

WRAPAI (2009): Document 8, Data Management Document, Appendix S 06 - Energy Research. Australia: Waste Refinery Australia Project Association Incorporated (WRAPAI)The Development and Use of Biogas Technology in Rural Areas of Asia (A Status Report 1981). Improving Soil Fertility through Organic Recycling

Chapter 4. Methane production by anaerobic digestion of wastewater and solid wastes

This chapter is part of a publication, commissioned by the Netherlands Agency for Energy and the Environment (Novem) on the status and perspectives of research and development in the field of high-tech biological production of methane and hydrogen. Chapter 4 gives a short but precise introduction the technological aspects of waste treatment by anaerobic digestion and the reuse of the produced biogas.

MES, T.Z.D. de STAMS, A.J.M. ZEEMAN, G. (2003): Chapter 4. Methane production by anaerobic digestion of wastewater and solid wastes. In: REITH, J.H. ; WIJFFELS, R.H. ; BARTEN, H. (2003): Biomethane and Biohydrogen. Status and perspectives of biological methane and hydrogen production. 58-94.Biogas Production from Agriculture and Food Industry Waste Slurry

Biogas Plants for Pig Farms

Typical Egg-shaped Biogas Reactor

Energy and Matter Reclamation from a Wastewater treatment plant

Process Flow Diagram for a typical large-scale treatment plant

Compendium of Sanitation Systems and Technologies (Arabic)

This is the Arabic version of the Compendium of Sanitation Systems and Technologies. The Compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. SCHERTENLEIB, R. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies (Arabic). 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) PDFOntario Large Herd Operators European Anaerobic Digestion Tour Report

Biogas Production in Climates with long cold Winters

This study analyses the feasibility and potential production of biogas in countries with a cold climate, with emphasis on Romania, Kyrgyzstan, Georgia, Kazakhstan and Armenia. The results are compared with China, Nepal and Bolivia. The study also carefully reviews existing literature before suggesting the same technology for the colder target communities. It also contains recommendations on whether to use the plants on household or community level afterwards.

BALASUBRAMANIYAM, U. ZISENGWE, L.S. MERIGGI, N. BUYSMAN, E. (2008): Biogas Production in Climates with long cold Winters. Wageningen: Wageningen University URL [Accessed: 31.05.2019]Development of biogas technology for livestock farms in Thailand

Dairy Waste Anaerobic Digestion Handbook. Options for Recovering Beneficial Products from Dairy Manure

This manual provides an introduction to the anaerobic digestion of dairy manure. The operation and waste management practices of Idaho dairies, the anaerobic digestion and the anaerobic digestion processes suitable for dairy waste, the typical design applications for different types of dairies and finally the cost and benefits of the facilities are discussed.

BURKE, P.E. Dennis, A. (2001): Dairy Waste Anaerobic Digestion Handbook. Options for Recovering Beneficial Products from Dairy Manure. Olympia: Environmental Energy CompanyDocument 8, Data Management Document, Appendix S 06 - Energy Research

This document provided by Waste Refinery Australia Project Association Inc. contains information on biogas, different types of cogeneration (CHP) and district heating. Additionally there are also facts and information on hydronics and gas flare.

WRAPAI (2009): Document 8, Data Management Document, Appendix S 06 - Energy Research. Australia: Waste Refinery Australia Project Association Incorporated (WRAPAI)Anaerobic Versus Aerobic Treatment in the USA

This study evaluated the feasibility of using anaerobic pre-treatment before aerobic polishing treatment for high-strength industrial wastewater (BOD values ranging form 200 to 5000 mg/L). The results indicated an economic feasibility at water strengths above 1000 mg/L, but treatability evaluation would be required for every specific industrial wastewater to confirm the technical feasibility.

ECKENFELDER, W.W. ; PATOZKA, J.B. ; PULLIAM, G.W. (1988): Anaerobic Versus Aerobic Treatment in the USA. In: Proceedings of the 5th International Symposium of Anaerobic Digestion: , 105-114 . URL [Accessed: 05.08.2010]Minnesota's Potential for Electricity Production Using Manure Biogas Resources

This report is a basic assessment of the feasibility and potential for using animal wastes in anaerobic methane digesters to create electricity in Minnesota. It covers an estimation of the electricity potential, the farm-size thresholds that warrant further investigation for a potential digester system, a quantification of the impact of incentives as well as a financial analysis.

MDC (2003): Minnesota's Potential for Electricity Production Using Manure Biogas Resources. Final Report. Minnesota: Minnesota Department of Commerce (MDC) and State Energy Office (SEO). [Accessed: 23.04.2010] PDFGreening Waste: Anaerobic Digestion for treating the organic Fraction of Municipal Solid Wastes

This paper outlines the processes of anaerobic digestion, reviews the current technology available for the anaerobic digestion of municipal organic wastes and proposes the adoption of the technology in the United States, beginning with commercial waste in New York City. The greatest concerns for New York are space and transportation, indicating that the most appropriate system is one using solid waste near the site of waste generation. A demonstration plant was constructed to show the improvement of local environmental conditions, job creation, and electricity generation in order to achieve support at policy level.

OSTREM, K. (2004): Greening Waste: Anaerobic Digestion for treating the organic Fraction of Municipal Solid Wastes. (= Master thesis ). Colombia: The Fu Foundation of School of Engineering and Applied Science, Columbia UniversityMarketing Compost. A Guide for Compost Producers in Low and Middle-Income Countries

This guide describes a marketing approach to composting, and is intended to help compost producers run more viable initiatives by unlocking the value of their product. The handbook does not cover everything there is to know about marketing, but starts with the basics and introduces the key principles and techniques. These include understanding the ‘marketing environment’, identifying appropriate target customer groups, and developing and promoting products to suit the market.

ROUSE ROTHENBERGER, S. ZURBRUEGG, C. (2008): Marketing Compost. A Guide for Compost Producers in Low and Middle-Income Countries. Duebendorf: Water and Sanitation in Developing Countries (SANDEC), Swiss Federal Institute for Environmental Science (EAWAG) URL [Accessed: 27.05.2019]Links between Sanitation, Climate Change and Renewable Energies

This factsheet of Sustainable Sanitation Alliance describes the impact of greenhouse gases on climate change and focuses on the advantages of renewable energies. Therefore many different technologies like production of biogas or short-rotation-plantations are mentioned.

SUSANA (2009): Links between Sanitation, Climate Change and Renewable Energies. Eschborn. (= SuSanA fact sheet 09/2009 ). Sustainable Sanitation Alliance (SuSanA) URL [Accessed: 26.05.2019]Agricultural Engineering in Support of the Kyoto Protocol. The Clean Development Mechanism for Biogas Technology

This paper discusses the potential of the Clean Development Mechanisms (CDMs) for the commercialisation of the small- to large- scale Integrated Biogas System (IBS). IBS utilises a system approach for the efficient management and conversion of agro-industrial waste into clean biogas and organic fertilizer. The methane captured could either be used for electricity generation in large/medium commercial enterprises or used for cooking, lighting and heating hot water in small-scale community.

UN (n.y): Agricultural Engineering in Support of the Kyoto Protocol. The Clean Development Mechanism for Biogas Technology. United Nations (UN) Asian and Pacific Centre for Agricultural Engineering and Machinery (APCAEM)Biogas Situation and Development in Thai Swine Farms

Full-Chain Sanitation Services That Last

This paper sets out a framework for the delivery of non-sewered sanitation services that last, are accessible to all and are at scale. The framework is based on IRC International Water and Sanitation’s (IRC) experience and lessons learnt from its engagement in non-sewered sanitation service at scale.

VERHAGEN, J. CARRASCO, M. (2013): Full-Chain Sanitation Services That Last. Non-Sewered Sanitation Services. The Hague: International Water and Sanitation Center (IRC) URL [Accessed: 03.06.2019]Anaerobic Reactors

Anaerobic Reactors is the forth volume in the series Biological Wastewater Treatment. The fundamentals of anaerobic treatment are presented in detail, including its applicability, microbiology, biochemistry and main reactor configurations. Two reactor types are analysed in more detail, namely anaerobic filters and especially UASB (upflow anaerobic sludge blanket) reactors. Particular attention is also devoted to the post-treatment of the effluents from the anaerobic reactors. The book presents in a clear and informative way the main concepts, working principles, expected removal efficiencies, design criteria, design examples, construction aspects and operational guidelines for anaerobic reactors.

LEMOS CHERNICHARO, C.A. de (2007): Anaerobic Reactors. (= Biological Wastewater Treatment Series , 4 ). London: International Water Association (IWA) Publishing. [Accessed: 01.11.2013]Sludge Treatment and Disposal

Sludge Treatment and Disposal is the sixth volume in the series Biological Wastewater Treatment. The book covers in a clear and informative way the sludge characteristics, production, treatment (thickening, dewatering, stabilisation, pathogens removal) and disposal (land application for agricultural purposes, sanitary landfills, landfarming and other methods). Environmental and public health issues are also fully described.

ANDREOLI, C.V. ; SPERLING, M. von ; FERNANDES, F. (2007): Sludge Treatment and Disposal. (= Biological Wastewater Treatment Series , 6 ). London: International Water Association (IWA) Publishing URL [Accessed: 27.05.2019]Biological Wastewater Treatment in Warm Climate Regions Volume 1

Biological Wastewater Treatment in Warm Climate Regions gives a state-of-the-art presentation of the science and technology of biological wastewater treatment, particularly domestic sewage. The book covers the main treatment processes used worldwide with wastewater treatment in warm climate regions given a particular emphasis where simple, affordable and sustainable solutions are required. The 55 chapters are divided into 7 parts over two volumes: Volume One: (1) Introduction to wastewater characteristics, treatment and disposal; (2) Basic principles of wastewater treatment; (3) Stabilisation ponds; (4) Anaerobic reactors; Volume Two (also available in the SSWM library): (5) Activated sludge; (6) Aerobic biofilm reactors; (7) Sludge treatment and disposal.

SPERLING, M. von LEMOS CHERNICHARO, C.A. de (2005): Biological Wastewater Treatment in Warm Climate Regions Volume 1. London: International Water Association (IWA) Publishing URL [Accessed: 26.05.2019]Biogas - Country Reports

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume IV summarises over 20 case studies from biogas sanitation as an appropriate technology in developing countries.

ISAT ; GTZ (1999): Biogas - Country Reports. (= Biogas Digest , 4 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ). [Accessed: 19.04.2010] PDFThailand Swine Farm Biogas Implementation Programs/Policies

Biogas from Sewage Treatment used to Electric Energy Generation, by a 30 kW (ISO) Microturbine

The sewage treatment process at SABESP (Basic Sanitation Company of Sao Paulo State, Brazil) has until now burnt some of the biogas produced in the anaerobic digester to enhance the process temperature and the other part was burnt in order to limit impact of emission. The transformation of this excess biogas into electricity would be a sustainable solution generating even additional income. An alternative to burn it in flare is the biogas conversion into electricity through engines or microturbines. This paper describes the proposed system to convert biogas in electricity and heat using microturbines (30 kW ISO).

TEIXEIRA COELHO, S. STORTINI GONZALES VELAZQUES, S.M. STELLA MARTINS, O. CASTRO DE ABREU, F. (2006): Biogas from Sewage Treatment used to Electric Energy Generation, by a 30 kW (ISO) Microturbine. (= World Bioenergy Conference & Exhibition ). Sao Paulo: Brazilian Reference Center on Biomass (CENBIO) URL [Accessed: 26.05.2019]Anaerobic Digestion of Biowaste in Developing Countries

This book published by Eawag/Sandec compiles existing and recently generated knowledge on anaerobic digestion of urban biowaste at small and medium scale with special consideration given to the conditions prevailing in developing countries. Written for actors working in the waste and renewable energy sector, the book is divided into two parts: Part 1 focuses on practical information related to the anaerobic digestion supply chain (substrate-, process-, and product chain), and Part 2 presents selected case studies from around the world.

VOEGELI, Y. LOHRI, C.R. GALLARDO, A. DIENER, S. ZURBRUEGG, C. EAWAG (2014): Anaerobic Digestion of Biowaste in Developing Countries. Practical Information and Case Studies. Duebendorf: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.05.2019]Anaerobic Methods of Waste Treatment

This technical factsheet describes the treatment of wastes through anaerobic digestion and biogas production at large-scale in a very comprehensive way. The treatment of different wastes, including sewage sludge, agricultural and industrial wastes or solid municipal wastes, is emphasised.

GATE (2000): Anaerobic Methods of Waste Treatment. Technical Information W2e. Frankfurt (Germany): German Agency for Technical Cooperation GmbH (GTZ) and German Appropriate Technology Exchange (GATE) URL [Accessed: 03.06.2019]Anaerobic Methods of Municipal Wastewater Treatment

Technical information on the advantages and main technologies of anaerobic digestion treatment for wastewaters in developing countries.

GATE (2001): Anaerobic Methods of Municipal Wastewater Treatment. Technical Information W3e. Frankfurt (Germany): GATE Information Service and Deutsche Gesellschaft für Technische Zusammenarbeit (GTZ) GmbH URL [Accessed: 03.06.2019]Biogas Plants in Animal Husbandry

This guide addresses the planners and providers of stock-farming and agricultural-extension services in developing countries. It is intended to serve as a source of information on the potentials of and prerequisites for biogas technology: a decision-making and planning aid for the construction and dissemination of biogas plants: a book of reference for information on practical experience and detailed data.

WERNER, U. STOEHR, U. HEES., N. (1989): Biogas Plants in Animal Husbandry. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbHFaecal Sludge Management. Lecture Notes

This module pays special attention to the haulage, treatment and reuse or disposal of faecal sludge. It covers both technical and non-technical (socio-cultural, economic, political etc.) aspects and provides practical information on design, financing and planning of faecal sludge treatment plants.

EAWAG/SANDEC (2008): Faecal Sludge Management. Lecture Notes. (= Sandec Training Tool 1.0, Module 5 ). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 23.05.2012]Biogas Basics

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume I tells you all you need to get an overview on biogas sanitation systems, from history over process and operation parameters to social, political and cultural issues.

ISAT ; GTZ (1999): Biogas Basics. (= Biogas Digest , 1 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GTZ) URL [Accessed: 03.06.2019]Biogas - Application and Product Development

The information service on biogas technology has been developed and produced on the behalf of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume II emphasises the design and operation of biogas plants.

ISAT ; GTZ (1999): Biogas - Application and Product Development. (= Biogas Digest , 2 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Technical Cooperation (GTZ) GmbH URL [Accessed: 03.06.2019]Biogas - Costs and Benefits and Biogas – Programme Implementation

This information service on biogas technology has been developed and produced on the order of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). Volume III discusses the micro- and macro-economic viability of biogas sanitation systems.

ISAT ; GTZ (1999): Biogas - Costs and Benefits and Biogas – Programme Implementation. (= Biogas Digest , 3 ). Information and Advisory Services on Appropriate Technology (ISAT) and German Agency for Technical Cooperation GmbH (GmbH) URL [Accessed: 26.05.2019]Biogas Plants

This rather old document still gives a good overview on biogas technology. It is intended to help designers of a biogas plant to be able to distinguish between valid and invalid solutions.

SASSE, L. (1988): Biogas Plants. German Appropriate Technology Exchange (GATE) and German Agency for Technical Cooperation (GTZ) GmbH URL [Accessed: 15.05.2012]…And Sewage, Too

This column by Rose George published in the New York Times emphasises the enormous potential wastewaters have as a renewable energy source.

GEORGE, R. (2010): …And Sewage, Too. In: The New York Times: , 25. URL [Accessed: 29.04.2010]Germany boosts biogas from new sewage treatment plant

German engineers have developed a high-rate processing plant that generates biogas from sewage.

EDIE NEWSROOM (2002): Germany boosts biogas from new sewage treatment plant. URL [Accessed: 06.08.2010]Waste? Not

Critical article on conventional end-of-pipe wastewater approaches, introducing some alternatives such as biogas digester, arborloos or the fossa alterna.

TUHUS-DUBROW (2008): Waste? Not. In: The Boston Globe: URL [Accessed: 21.02.2010]Biogas production and usage in Kaunas Sewage plant

Kaunsas is the second-largest city in Lithuania and is located at the confluence of the two largest Lithuanian rivers, the Nemunas and the Neris, and near the Kaunas reservoir, the largest body of water entirely in Lithuania. In 1999, a large-scale biogas plant (comprising four sedimentation tanks and four anaerobic digesters) was put in operation, being the first sewage plant in Kaunas’ history. The produced biogas is transformed into energy in a cogeneration plant with 150 kW heat and 226 kW power output (see also http://www.lei.lt/Opet/Projekts/cooger_unit.htm).

Waste-to-Energy Plant is Ivory Coast’s First CDM Project

A French carbon dealer (ecosur) has registered a waste-to-energy carbon-offset project in Côte d'Ivoire under the Kyoto Protocol's Clean Development Mechanism. The project is based on the anaerobic digestion of municipal solid waste. It's the first CDM project in the West African Economic and Monetary Union (UEMOA), and one of the few in sub-Saharan Africa outside of South Africa.

International Seminar on Biogas Technology for Poverty Reduction and Sustainable Development

This webpage presents the proceedings of the International Seminar on Biogas Technology for Poverty Reduction and Sustainable Development, jointly sponsored by the United Nations Economic and Social Commission for Asia and the Pacific (UNESCAP) and the Ministry of Agriculture of China (MOA) (18 to 20 October, 2005, Beijing). Utilisation of household biogas systems and large-scale biogas systems as a means to boost rural economy, while contributing to rural poverty reduction and sustainable development are discussed.

Biogas processes for sustainable development

This review is intended to up-date students, practitioners and consultants concerned with Biogas technologies, and to contribute to bringing biogas systems to a more advanced stage, and thereby to achieve a palpable impact in developing countries. Technical, social, environmental ad economic issues are addressed.