Executive Summary

A non-planted filter is a box filled with sand and gravel, through which wastewater flows and is filtered. There are several types of non-planted filters. The most successful is a vertical-flow filter in combination with a pre-treatment facility (e.g. septic tank or grease trap). Wastewater can be treated efficiently, but clogging of the filter body is a common problem. Pre-settled greywater or effluents of primary and secondary blackwater treatments is applied intermittently to the surface of a filter media (generally gravel and sand of different granulometry), percolates through an unsaturated filter zone where physical, biological (aerobic) and chemical processes treat the water. The treated greywater is collected in a drainage network or infiltrates the underlying soil. It is a big improvement for its users, because the effluent of a well functioning non-planted filter is harmless and can be used for irrigation.

| In | Out |

|---|---|

Fertigation Water, Treated Water |

Introduction

Unplanted vertical-flow sand or gravel filters are frequently and successfully applied for pre-settled domestic greywater throughout the world, even in regions with cold winters such as Canada, Germany, Switzerland, Norway or Sweden (MOREL & DIENER 2006). They can also be applied for the tertiary treatment of the effluents from primary or secondary blackwater treatments (e.g. biogas settlers; anaerobic baffled reactors; waste stabilisation ponds; or horizontal flow, vertical flow or free surface constructed wetlands)

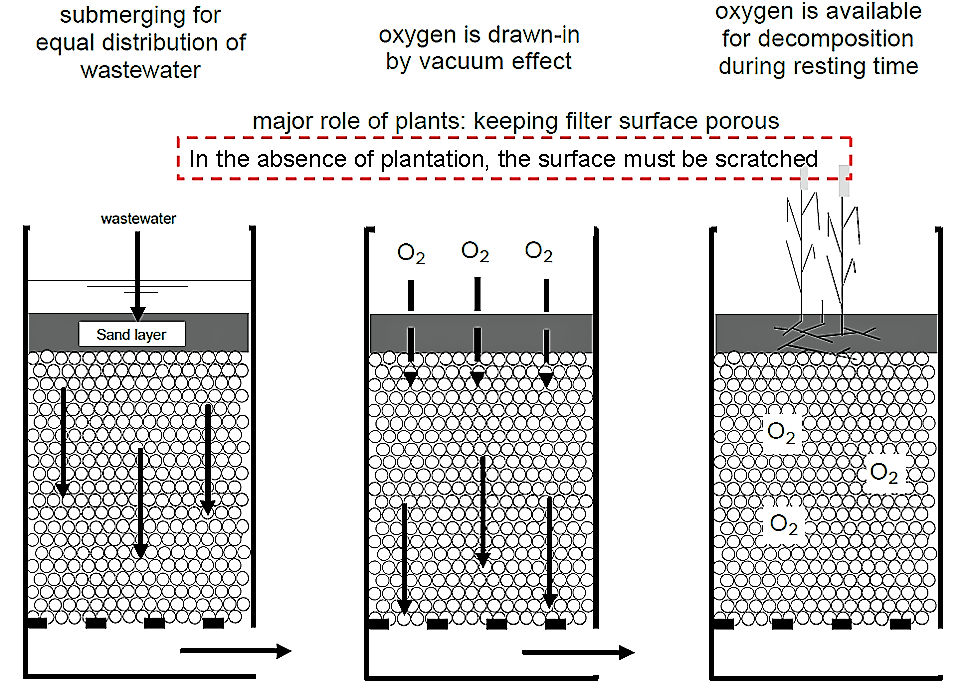

The design of a non-planted filter system is very similar to the design of constructed wetlands (see also horizontal flow, vertical flow or free surface). In constructed wetlands, the plants may have a positive effect on breaking up the biological clogging layer on the filter surface, but apart form that there is not much difference in the system performance between planted and unplanted systems. In fact, the sand filter system for greywater purification has been in use for more than 100 years, thus it is a well-known application (HEEB et al. 2007). Non-planted filters are also referred to as subsurface biofilters, percolation beds, infiltration beds or intermittent sand filters (MOREL & DIENER 2006).

Treatment process and basic design principles

Greywater undergoes physical, chemical and biological treatment in a non-planted sand filter. Suspended solids are removed by mechanical filtering and sedimentation, and degradation occurs by microorganisms that colonise the filter bed. Since organic matter and nutrients in the wastewater allow microorganisms to grow and reproduce, the organic matter is mineralised and nutrients are partly removed. Chemical adsorption of pollutants onto the media surface also plays a role in removal of some chemical constituents (e.g. phosphorus, surfactants). Although different materials, such as pea gravel, peat or crushed glass, can be applied as filter media in non-planted filters, sand is the most widespread material used. A combination of different filter material of different granulometry (e.g. gravel, sand and mulch) has also been observed. The combination of the filter material depends on the wastewater quality. For a better phosphorous removal, sand with a higher Fe content is requested (MOREL & DIENER 2006).

Pre-treatment

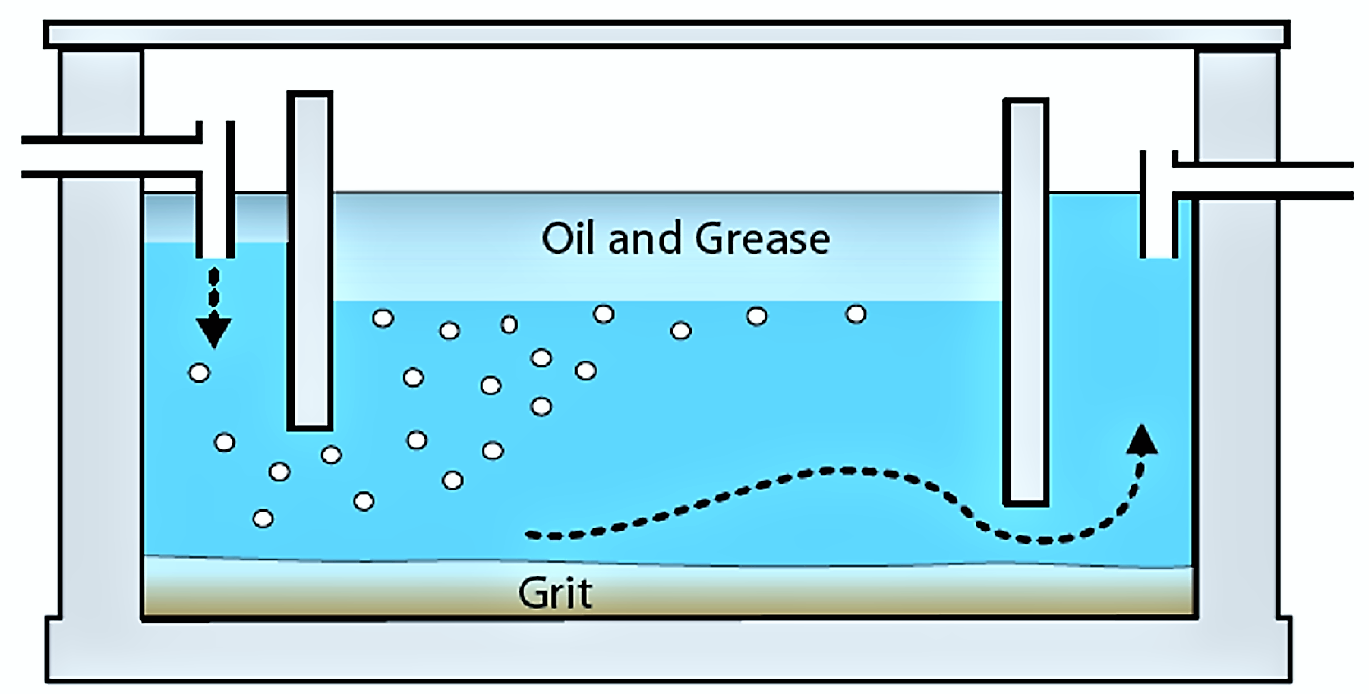

Before the pre-treated wastewater or greywater enters the filter body, a pre-treatment is very important to remove oil, grease and solid materials (e.g. kitchen waste). Otherwise the risk of clogging the filter bed is high. Septic tanks or Anaerobic Baffled Reactor are a common solution for primary treatment. Also a simple grease trap (see picture below) is an appropriate possibility for single households.

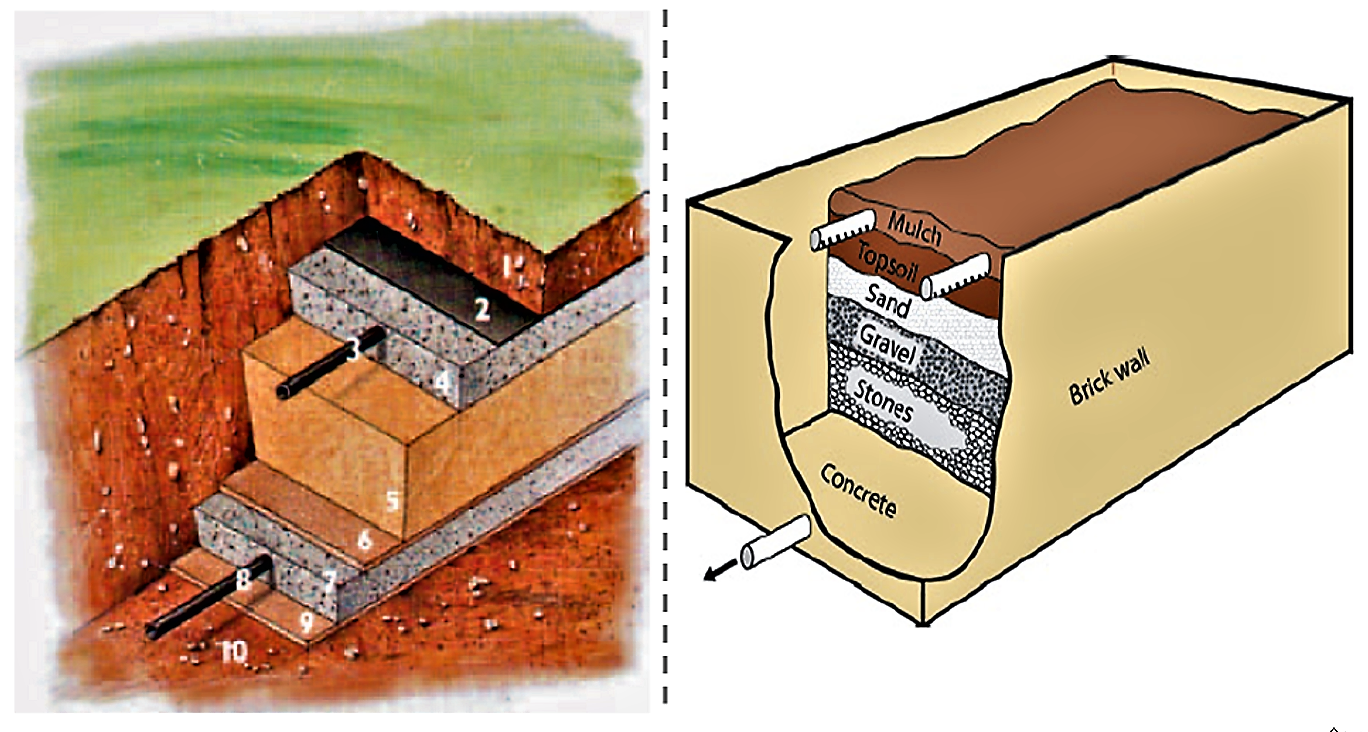

Filter body

The basic structure consists of a watertight box filled with filter material. Greywater is applied to the top of the filter body, percolates through an unsaturated zone of porous material and is then collected in a drainage system. The water is applied intermittently and evenly on the filter surface by a pressure distribution device such as an electric pump or mechanical siphon. By charging the entire surface of the filter, oxygen is supplied to the filter media (MOREL & DIENER 2006).

The most usual depth of vertical filters is 1 m to 1.20 m. However, if there is enough natural slope and good ventilation of the influent (e.g. by sprinkling the wastewater on the filter surface to enhance the contact with air), vertical filters can also be built up to a depth of 3 metres. In the absence of plantation, the surface must be scratched at the beginning of the resting period, in order to allow enough oxygen to enter (SASSE 1998).

Loading of a vertical filter

Feeding in doses is necessary for equal water distribution. The resting times are needed to enable oxygen to enter the filter after wastewater has percolated. Doses must be large enough to completely flood the filter for a short while in order to distribute the water evenly over the surface and small enough to allow enough time for oxygen to enter before the next flooding. Correspondingly, the filter material must be fine enough to cause flooding and porous enough to allow quick percolation (SASSE 1998). Uniform distribution of greywater onto the filter surface is essential and can be achieved either through a dense network of perforated pipes or a sprinkler system (MOREL & DIENER 2006).

Performance

A properly operated non-planted sand filter can produce high-quality effluent with less than 10 mg/l BOD (90–95% removal) and less than 10 mg/l TSS (90–95%). Nitrogen removal is rather limited (30–40%) (MOREL & DIENER 2006). Bacteria, virus and phosphorus removal is enhanced when using sand rich in iron oxides (HEEB et al. 2007). However, the current operational vertical flow filter concepts re-circulate the nitrified effluent from the filter bed back through the anaerobic primary treatment of the system (e.g. septic tank or anaerobic baffled reactor) where denitrification occurs. The recirculating vertical flow filter system is very efficient at removing nitrogen (up to 95%), however, the complexity of the system makes it inappropriate for application on household level in low and middle-income countries (MOREL & DIENER 2006). The treated effluent of a non-planted filter can be used as irrigation water, fertigation water, or for surface or sub-surface groundwater recharge.

Costs considerations

Capital costs are moderate. Spatial requirements reduce cost for land purchase. Costs for materials are less if they are locally available (SANIMAS 2005). The pre-treatment facility, which is very important to prevent clogging of the filter bed, must be maintained and emptied regularly. Furthermore, use of feeder pumps increase operational costs (SANIMAS 2005) as well as maintenance and periodically emptying of the pre-treatment facility (e.g. septic tank).

Operation and maintenance

Regular maintenance works at the treatment facility comprises removal of unwanted vegetation from filter bed and cleaning of the inlet/outlet systems. The sludge from the pre-treatment system is desludged regularly (depends on system) and disposed correctly (e.g. drying beds). The filter bed maintenance becomes more complicated when it is covered (UN-HABITAT 2008).

Health aspects

A non-planted filter in combination with a pre-treatment facility is a big improvement for health issues of the community and its surroundings. The effluent of the filter is widely harmless.

The health risk which arises from settled wastewater in the pre-treatment facility should be considered during inspections and emptying. Mechanical emptying in a vacuum truck or a manual technology like a sludge gulper can decrease the health risks (see also human-powered emptying and transport and motorised emptying and transport) (TILLEY et al. 2008).

At a glance

| Working principle | Pre-treated greywater is applied intermittently to the surface of a filter media and percolates through an unsaturated filter zone where physical, biological and chemical processes treat the water. The treated greywater is collected in a drainage network or infiltrates the underlying soil (Adapted from MOREL & DIENER 2006). |

| Capacity/adequacy | It can be applied for single households or small communities. Also applicable in regions with cold climates. |

| Performance | BOD = 80 to 90%; TSS = 65 to 85%; TN 30 to 40%; FC ≤ 1 to 2 log; MBAS ~ 90%; (Adapted from: MOREL & DIENER 2006) |

| Costs | Investment costs depend on type of filter materials and feeder pumps used; operational costs determined by electricity consumption of feeder pumps. |

| Self-help compatibility | Can be built with local material but needs expert design. Electricity pumps may be necessary. |

| O&M | Emptying of pre-settled sludge, removal of unwanted vegetation, cleaning of inlet/outlet systems |

| Reliability | Clogging of the filter bed is the main risk of this system, but treatment performance is satisfactory. |

| Main strength | Efficient removal of suspended and dissolved organic matter, nutrients, pathogens, and surfactants. It is applicable in regions with cold climates |

| Main weakness | Clogging of the filter body |

A non-planted filter is applicable for greywater in combination with a pre-settling unit for single households and small communities or as a tertiary treatment for effluents from primary and secondary wastewater treatments. If it is covered with a top layer of soil, it is a well functioning system in regions with cold climates (e.g. Canada or Sweden). The main risk of the filter is clogging, therefore it is very important that the pre-treatment of the greywater works well and solids and oil/grease will be separated properly. Furthermore a permanent supply of water is necessary.

M3: Ecosan Systems and Technology Components. M 3-2: Ecosan Technologies to Close the Water Loop

This presentation is adapted from the Ecosan Curriculum 2.2. The ecosan curriculum was created in order to compile the large amount of information on ecological sanitation in a structured and comprehensive way. This is a summary about the various Ecosan (or more: sustainable sanitation) systems.

HEEB, J. JENSSEN, P. GNANAKAN, K. CONRADIN, K. (2007): M3: Ecosan Systems and Technology Components. M 3-2: Ecosan Technologies to Close the Water Loop. In: HEEB, J. ; JENSSEN, P. ; GNANAKAN ; CONRADIN, K. ; (2008): Ecosan Curriculum 2.3. Switzerland, India and Norway: .Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods

This report compiles international experience in greywater management on household and neighbourhood level in low and middle-income countries. The documented systems, which vary significantly in terms of complexity, performance and costs, range from simple systems for single-house applications (e.g. local infiltration or garden irrigation) to rather complex treatment trains for neighbourhoods (e.g. series of vertical and horizontal-flow planted soil filters).

MOREL, A. DIENER, S. (2006): Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods. (= SANDEC Report No. 14/06 ). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 27.05.2019]Introduction to Greywater Management

The report gives a comprehensive description of the main components in successful greywater management. Examples as well as recommendations are given for designing and dimensioning treatment systems.

RIDDERSTOLPE, P. (2004): Introduction to Greywater Management. (= EcoSanRes Publication Series, Report 2004-4 ). Stockholm: Stockholm Environment Institute, EcoSanRes Programme URL [Accessed: 19.05.2010]Informed Choice Catalogue

This informed choice catalogue for community based wastewater treatment technologies helps to identify suitable sanitation options and facilitates the assessment of different sanitation system components with regard to stakeholder preferences. A powerful tool for technical bottom-up planning giving overall information about technical options at a "glance".

SANIMAS (2005): Informed Choice Catalogue. pdf presentation. BORDA and USAID URL [Accessed: 29.05.2019]DEWATS

Exhaustive report on technological, operational and economic aspects of decentralised waste water treatment systems. Spreadsheet examples support the reader in designing and planning waste water treatment systems components.

SASSE, L. BORDA (1998): DEWATS. Decentralised Wastewater Treatment in Developing Countries. Bremen: Bremen Overseas Research and Development Association (BORDA) URL [Accessed: 03.06.2019]Compendium of Sanitation Systems and Technologies

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E., LUETHI, C., MOREL, A., ZURBRUEGG, C. and SCHERTENLEIB, R. (2008): Compendium of Sanitation Systems and Technologies. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) and Water Supply and Sanitation Collaborative Council (WSSCC) URL [Accessed: 15.02.2010] PDFConstructed Wetlands Manual

This manual has been prepared as a general guide to the design, construction, operation and maintenance of constructed wetlands for the treatment of domestic wastewater as well as introduction to the design of constructed wetland for sludge drying.

UN-HABITAT (2008): Constructed Wetlands Manual. Kathmandu: UN-HABITAT, Water for Asian Cities Program URL [Accessed: 15.02.2012]M3: Ecosan Systems and Technology Components. M 3-2: Ecosan Technologies to Close the Water Loop

This presentation is adapted from the Ecosan Curriculum 2.2. The ecosan curriculum was created in order to compile the large amount of information on ecological sanitation in a structured and comprehensive way. This is a summary about the various Ecosan (or more: sustainable sanitation) systems.

HEEB, J. JENSSEN, P. GNANAKAN, K. CONRADIN, K. (2007): M3: Ecosan Systems and Technology Components. M 3-2: Ecosan Technologies to Close the Water Loop. In: HEEB, J. ; JENSSEN, P. ; GNANAKAN ; CONRADIN, K. ; (2008): Ecosan Curriculum 2.3. Switzerland, India and Norway: .Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods

This report compiles international experience in greywater management on household and neighbourhood level in low and middle-income countries. The documented systems, which vary significantly in terms of complexity, performance and costs, range from simple systems for single-house applications (e.g. local infiltration or garden irrigation) to rather complex treatment trains for neighbourhoods (e.g. series of vertical and horizontal-flow planted soil filters).

MOREL, A. DIENER, S. (2006): Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods. (= SANDEC Report No. 14/06 ). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 27.05.2019]Introduction to Greywater Management

The report gives a comprehensive description of the main components in successful greywater management. Examples as well as recommendations are given for designing and dimensioning treatment systems.

RIDDERSTOLPE, P. (2004): Introduction to Greywater Management. (= EcoSanRes Publication Series, Report 2004-4 ). Stockholm: Stockholm Environment Institute, EcoSanRes Programme URL [Accessed: 19.05.2010]Informed Choice Catalogue

This informed choice catalogue for community based wastewater treatment technologies helps to identify suitable sanitation options and facilitates the assessment of different sanitation system components with regard to stakeholder preferences. A powerful tool for technical bottom-up planning giving overall information about technical options at a "glance".

SANIMAS (2005): Informed Choice Catalogue. pdf presentation. BORDA and USAID URL [Accessed: 29.05.2019]DEWATS

Exhaustive report on technological, operational and economic aspects of decentralised waste water treatment systems. Spreadsheet examples support the reader in designing and planning waste water treatment systems components.

SASSE, L. BORDA (1998): DEWATS. Decentralised Wastewater Treatment in Developing Countries. Bremen: Bremen Overseas Research and Development Association (BORDA) URL [Accessed: 03.06.2019]Greywater Treatment in an Oasis Town, Béni Abbès, Béchar, Algeria

Water resources are limited in the oasis town of Béni Abbès. Efficient resource planning is complicated due the deficit of reliable data on demand, supply, and use of water. To improve the data collection, GIZ introduced an IWRM project at the oasis in order to get a sufficiently account for all demands on the available water resources. The main objective of the sanitation activities of this IWRM project is to support the elaboration of an overall strategy for the future management of all wastewater, ensuring the collection and treatment of the generated wastewater within the oasis and to maximise its reuse potential. This SuSanA case study presents only the greywater part of the wastewater concept. The greywater treatment and reuse systems used in the project were designed to collect, treat and reuse greywater coming from kitchen sinks and wash hand basins.

BRACKEN, P. (2012): Greywater Treatment in an Oasis Town, Béni Abbès, Béchar, Algeria. Case Study of Sustainable Sanitation Projects. Béni Abbès, Béchar, Algeria : Sustainable Sanitation Alliance (SuSanA) URL [Accessed: 10.06.2019]