Executive Summary

The compost filter is a fairly new method for pre-treating wastewater. There are two different methods: two chamber compost filters or compost filter bags. Greywater or domestic wastewater flows directly into this filter. The solids stay in the filter and are decomposed and transformed into humus by aerobic digestion; the liquids are drained at the bottom and forwarded to the constructed wetland. As it is an aerobic process, there are neither biogas emissions nor bad odours. From time to time, the operator has to add bulking material like straw or wood chips, to enforce the dehydration and to avoid clogging of the filter.

| In | Out |

|---|---|

Blackwater, Compost/Biosolids |

Treatment process and basic design principles

A compost filter, called ‘Rottebehälter’ in German, is a novel alternative pre-treatment method (instead of a septic tank, biogas settler, anaerobic baffled reactor, imhoff tank or UASB reactors) typically applied prior to constructed wetlands (see also vertical flow, horizontal flow and free-surface constructed wetlands) or waste stabilisation ponds. Composting filters are particularly useful where biogas emissions have to be avoided. As it is an aerobic process, no bad odours occur if it is correctly operated. Compost filters used in combination with the above mentioned constructed wetlands or ponds are mainly used for semi-centralised or on-site wastewater treatment facilities for small communities after a simplified sewer system (see also simplified and condominal sewers and solids-free sewers) or single households; effluents of the system may be used for irrigation (see also drip irrigation or fertigation). There are two types of compost filters (chamber or bags).

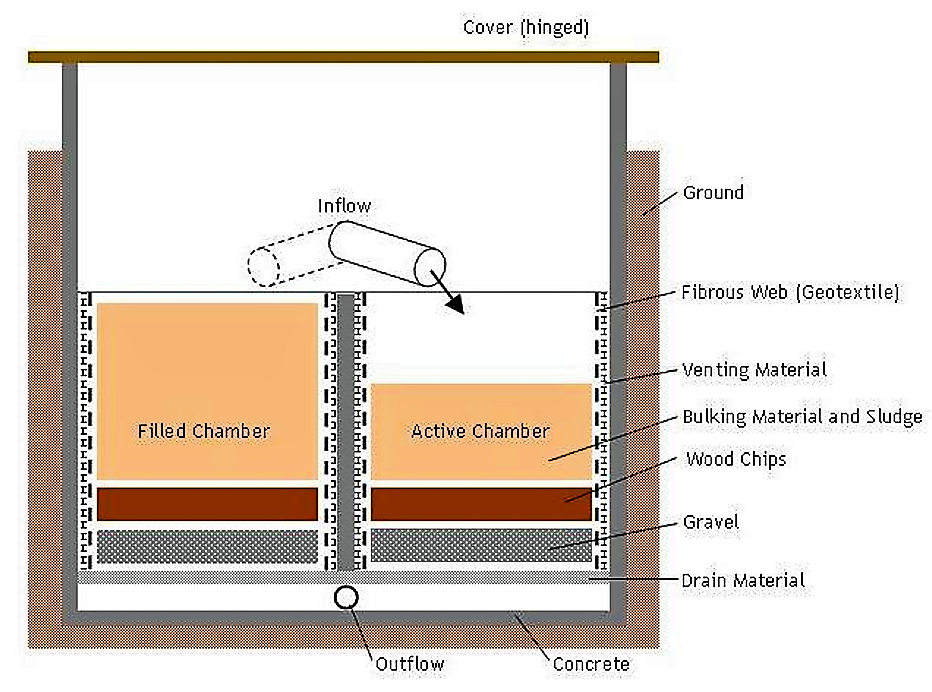

Two chamber compost filter

This system is also used in cold climates like Switzerland. Experience has shown that it works well up to 40 p.e. The wastewater flows directly into the composting filter. It consists of two chambers; each chamber has a capacity of one year. As soon as the first chamber is full, the influent pipe can be switched to the second chamber for the following year. In the meantime, the faecal sludge in the first chamber is dewatered, and the rotting process (aerobic digestion) successively decomposes the material (BALLY and BITTNER 2009).

Two chamber composting filters consist of two concrete chambers, fibrous web (geomembrane), drainage slabs, gravel, and wood chips. The compost filter is usually covered to prevent the entry of precipitation water and to protect people from falling into the chambers. A proper construction of the drainage and filter layer is important. The filter layer should not be too coarse, otherwise solids and sewage sludge could end up in the collection chamber. This could damage the pump or the following treatment facility (e.g. vertical flow constructed wetland). However, if the pores in the composting filter are too small, it may lead to clogging and anaerobic conditions, or overflowing of the filter (LACK 2006).

The filter passage in a compost filter is short and oxygen depletion hardly occurs. This is also why a properly maintained compost filter does not smell bad. A slight smell can however occur as is known from sewer systems. Due to the low oxygen consumption, the percentage of O2 in the water is still high enough to support microbiological processes in the subsequent constructed wetland (see vertical flow, horizontal flow and free-surface constructed wetlands) (BALLY and BITTNER 2009).

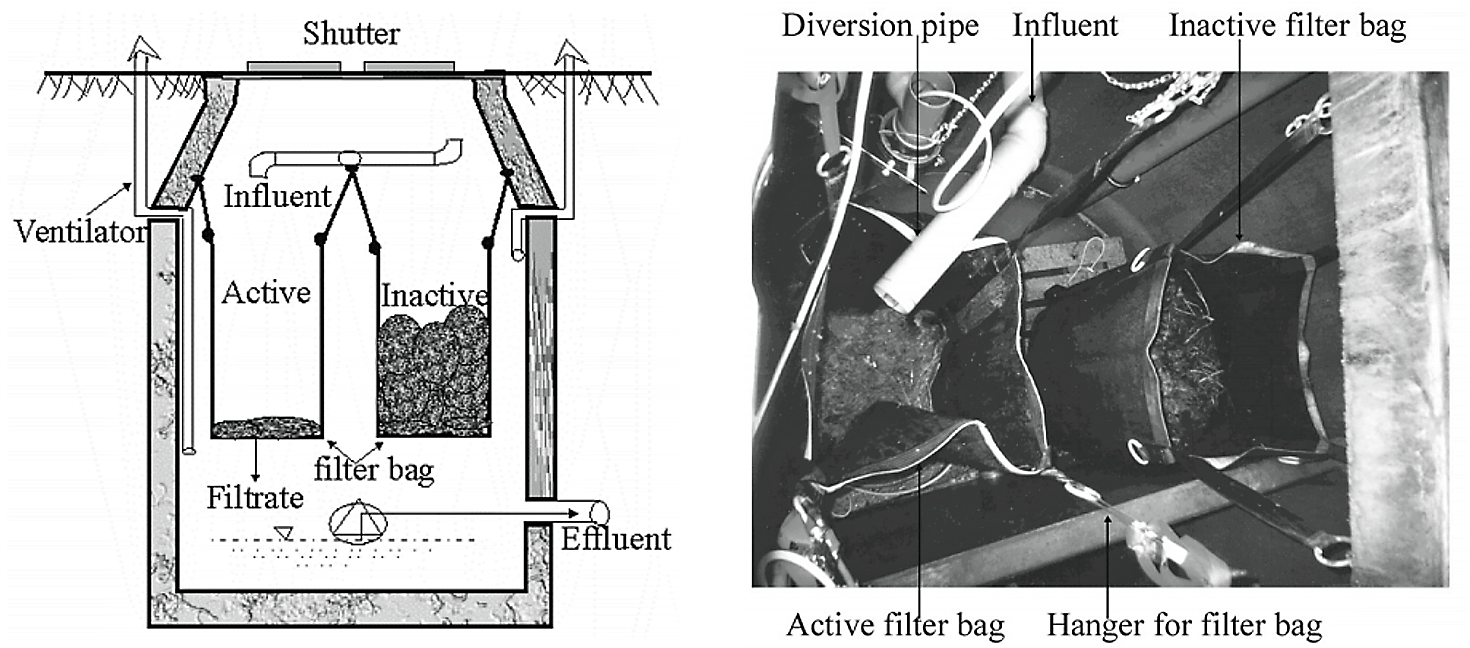

Compost filter bags

So far this type has only been used for single households or up to 70 p.e. for example in ecological sanitation (ecosan) projects, where concentrated blackwater requires pre-treatment (HOFFMANN et al. 2010).

The raw blackwater passes through a filter bag (made of plastic material) into a chamber with a ventilation pipe. The liquid effluent from the compost filter is collected below the filter bags and normally needs to be pumped to the constructed wetland, as the hydraulic head loss in compost filters is about 1.5 m. The solid components of the blackwater (i.e. faeces and toilet paper) are retained in the straw bed, which is contained in the filter bag (HOFFMANN et al. 2010).

The final product

The final product (after it has been fully aerated and left without addition of new material for 6 to 12 months) is black, compact material, which looks and smells like black soil or humus. Nevertheless, the material still needs secondary composting (see small and large scale composting) as it still contains pathogens such as helminth eggs (HOFFMANN et al. 2010).

Cost considerations

Compared to other water based systems, construction costs are relatively low. However, it is still more expensive than a dry toilet or composting toilet system. Nevertheless it is a valuable option for primary treatment in decentralised sanitation systems in combination with constructed wetlands or waste stabilisation ponds. A compost filter needs expert design and constant input of straw or wood chips.

Operation and maintenance

The compost filter bag needs regular maintenance. Once a week dry straw has to be added. Generally, 2 to 4 filter bags are used in alternating modes in two separate chambers (the dimensions of the chambers depend on the number of users); the retained solids are composted during the resting phase of 6 months, during which the second bag is used. Volume reduction during resting phase can be up to 75% (HOFFMANN et al. 2010).

An operator must maintain the active chamber of the two-chamber filter regularly: dry material such as straw or wood chips must be added weekly to monthly. This avoids clogging of the filter and advances the dehydration process. It is recommended, that the added material be arranged all over the compost filter surface. It should be slightly accumulated directly below the influent. If the filter is correctly maintained and operated, no unpleasant odour can develop.

Health aspects

The chambers need to be covered in order to prevent people (especially children) from falling in. The active chamber contains fresh excreta. The material of the inactive chamber is less hazardous, but could still contain pathogens. Therefore, gloves are recommended for any maintenance or repair work of the filter. The decomposed material should be composted again, as a further hygienisation (see small and large scale composting). It is also important to apply this material correctly if it is used for agriculture.

At a glance

| Working principle | The raw blackwater passes through a filter bag/chamber. The liquid effluent from the compost filter is collected below the filter and normally needs to be pumped to the constructed wetlands. The solid components of the blackwater (i.e. faeces and toilet paper) are retained in the compost filter. |

| Capacity/adequacy | Compost filters are used by small communities for primary treatment of grey- and blackwater. |

| Performance | High |

| Costs | Compared to other water based systems, construction costs are relatively low. |

| Self-help compatibility | High, once it is constructed |

| O&M | Must be maintained regularly by unskilled labourers |

| Reliability | Reliable if designed and operated correctly, problems might occur with shock loads. |

| Main strength | No bad odour, produces compost, no biogas emission |

| Main weakness | Risk of clogging and anaerobic conditions if not operated correctly. |

Compost filters are suitable for domestic waste- or greywater with high organic load. So far compost filters were constructed for single households and small communities (up to 70 p.e.) (HOFFMANN et al. 2010). It is a very convincing and ecological pre-treatment method for constructed wetlands and experience in Switzerland has shown that this system also works in colder climates. Further treatment (e.g. composting) of the filter material must be available.

Pflanzenklaranlagen – Die okologische Alternative zur technischen Kleinklaranlage

This article (in German) describes a constructed wetland system with a compost filter as a first treatment step.

BALLY, A. ; BITTNER, K. (2009): Pflanzenklaranlagen – Die okologische Alternative zur technischen Kleinklaranlage. In: Fachzeitschrift “Verein für Ingenieurbiologie" 4/09: , 80-85. URL [Accessed: 14.11.2011]Investigation of the Effectiveness of Source Control Sanitation Concepts Including Pre-Treatment with Rottebehaelter

This paper shows the effectiveness and limitations of source control sanitation concepts with pre-treatment by pre-composting tanks (Rottebehaelter) to recover the particulate fraction of nutrients from household wastewater.

GAJUREL, D.R. ; LI, Z. ; OTTERPOHL, R. (2010): Investigation of the Effectiveness of Source Control Sanitation Concepts Including Pre-Treatment with Rottebehaelter. In: Water Science and Technology : Volume 48 , 111–118. URL [Accessed: 02.06.2019]Technology Review of Constructed Wetlands

This publication intends to help spread awareness and knowledge about the technology of subsurface flow constructed wetlands in developing countries. Constructed wetlands (CWs) can be used as part of decentralised wastewater treatment systems, due to their “robust”, “low-tech” nature with none or few moving parts (pumps) and relatively low operational requirements. CWs can be used for the treatment of domestic and municipal wastewater or greywater, and play an important role in many ecological sanitation (ecosan) concepts.

HOFFMANN, H. PLATZER, C. WINKER, M. MUENCH, E. von GIZ (2011): Technology Review of Constructed Wetlands. Subsurface Flow Constructed Wetlands for Greywater and Domestic Wastewater Treatment. Eschborn: Deutsche Gesellschaft fuer Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 01.06.2019]Abwasserreinigung mit Pflanzen – Bau für 4 bis 400 Einwohner

Pflanzenklaranlagen – Die okologische Alternative zur technischen Kleinklaranlage

This article (in German) describes a constructed wetland system with a compost filter as a first treatment step.

BALLY, A. ; BITTNER, K. (2009): Pflanzenklaranlagen – Die okologische Alternative zur technischen Kleinklaranlage. In: Fachzeitschrift “Verein für Ingenieurbiologie" 4/09: , 80-85. URL [Accessed: 14.11.2011]Investigation of the Effectiveness of Source Control Sanitation Concepts Including Pre-Treatment with Rottebehaelter

This paper shows the effectiveness and limitations of source control sanitation concepts with pre-treatment by pre-composting tanks (Rottebehaelter) to recover the particulate fraction of nutrients from household wastewater.

GAJUREL, D.R. ; LI, Z. ; OTTERPOHL, R. (2010): Investigation of the Effectiveness of Source Control Sanitation Concepts Including Pre-Treatment with Rottebehaelter. In: Water Science and Technology : Volume 48 , 111–118. URL [Accessed: 02.06.2019]Technology Review of Constructed Wetlands

This publication intends to help spread awareness and knowledge about the technology of subsurface flow constructed wetlands in developing countries. Constructed wetlands (CWs) can be used as part of decentralised wastewater treatment systems, due to their “robust”, “low-tech” nature with none or few moving parts (pumps) and relatively low operational requirements. CWs can be used for the treatment of domestic and municipal wastewater or greywater, and play an important role in many ecological sanitation (ecosan) concepts.

HOFFMANN, H. PLATZER, C. WINKER, M. MUENCH, E. von GIZ (2011): Technology Review of Constructed Wetlands. Subsurface Flow Constructed Wetlands for Greywater and Domestic Wastewater Treatment. Eschborn: Deutsche Gesellschaft fuer Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 01.06.2019]Design of Highly Efficient Source Control Sanitation and Practical Experiences

This paper explains the problem of conventional sanitation systems and provides solutions. How can nutrients be reused, how can wastewater be treated ecologically and how should water be managed.

OTTERPOHL, R. (2000): Design of Highly Efficient Source Control Sanitation and Practical Experiences. Wageningen: EURO-Summer School DESAR URL [Accessed: 02.06.2019]Blackwater and greywater reuse system, Chorrillos, Lima, Peru

The following technologies were installed in the education centre “San Christoferus”: Constructed wetland for greywater treatment; compost filter for blackwater treatment; and double-vault urine diversion dehydration toilets. The aim of the project was to reduce water consumption and limit the wastewater flowing to the public sewer system, of which the largest part is discharged without treatment.

HOFFMANN, H. RUEN, S. SCHOEPE, A. (2009): Blackwater and greywater reuse system, Chorrillos, Lima, Peru. (= SuSanA - Case Studies ). Eschborn: Sustainable Sanitation Alliance (SuSanA) URL [Accessed: 02.06.2019]Vermicomposting of Sieved Blackwater using the Rottebehaelter System

This project tried to combine vermin-composting with a compost filter bag system.

SHALABI, M. GAJUREL, D.R. OTTERPOHL, R. (n.y): Vermicomposting of Sieved Blackwater using the Rottebehaelter System. Hamburg: Technische Universität Hamburg-Harburg URL [Accessed: 29.01.2012]