Executive Summary

The aim of a distribution network is to supply a community with the appropriate quantity and quality of water. There are four network types: dead end, gridiron, circular and radial systems. Investment costs for network construction (material, labour, planning for pipes and trenches) as well as maintenance costs (repair, pumping station, leakage control, preventing recontamination) are high.

| In | Out |

|---|---|

Freshwater, Drinking Water, Treated Water |

Introduction

Networks are a system of pipes and trenches providing the appropriate quality and quantity of water to a community. The network construction and layout have to be carefully prepared in order to guarantee enough pressure and ensure hygienically safe water. Once constructed, maintenance – including repair, leakage control, preventing recontamination, etc. and the operation of pumping stations were gravity pressure is not enough– has to be ensured.

Requirements of an adequate distribution system

Adapted from NPTEL (n.y.)

- Water quality should not deteriorate while in the distribution pipes.

- The system should be capable of supplying water to all the intended places with sufficient pressure head.

- It should be capable of supplying the requisite amount of water during fire fighting.

- The layout should be such that no consumer is without water supply, during the repair of any section of the system.

- All the distribution pipes should preferably be laid one metre from or above sewer lines.

- It should be fairly watertight to keep losses (e.g. due to leakage) to a minimum.

Network types

Adapted from GONU (2009)

There are four principal methods to design a distribution system:

- Dead end or tree system

- Gridiron system

- Circular or ring system

- Radial system

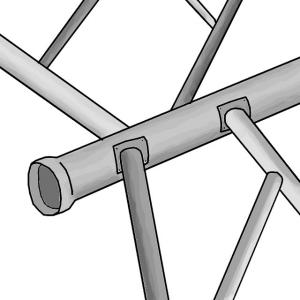

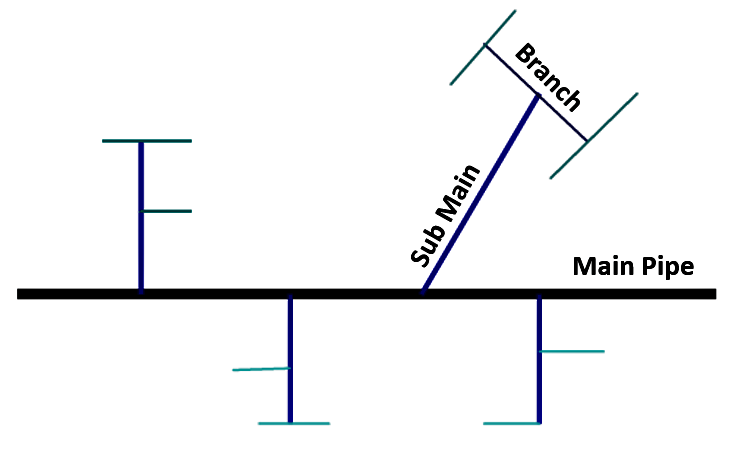

1. Dead-end or tree distribution system

|

Description In the dead end system (also called tree system), one main pipeline runs through the centre of the populated area and sub-mains branch off from both sides. The sub-mains divide into several branch lines from which service connections are provided. |

|

|

Advantages dead-end System:

|

|

Disadvantages dead-end system:

|

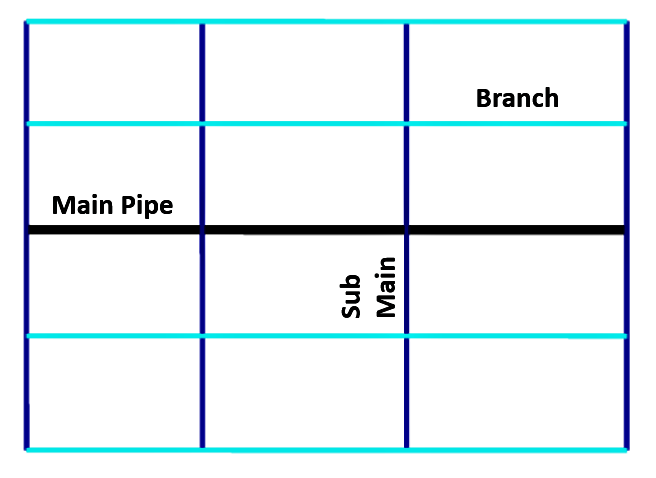

2. Gridiron distribution system

|

Description: In this system the main supply line runs through the centre of the area and sub mains branch off in perpendicular directions. The branch lines interconnect the sub-mains. This system is ideal for cities laid out on a rectangular plan resembling a gridiron. The distinguishing feature of this system is that all of the pipes are interconnected and there are no dead ends. Water can reach a given point of withdrawal from several directions, which permits more flexible operation, particularly when repairs are required. |

|

|

Advantages of the Gridiron distribution system:

|

|

Disadvantages of the Gridiron distribution system:

|

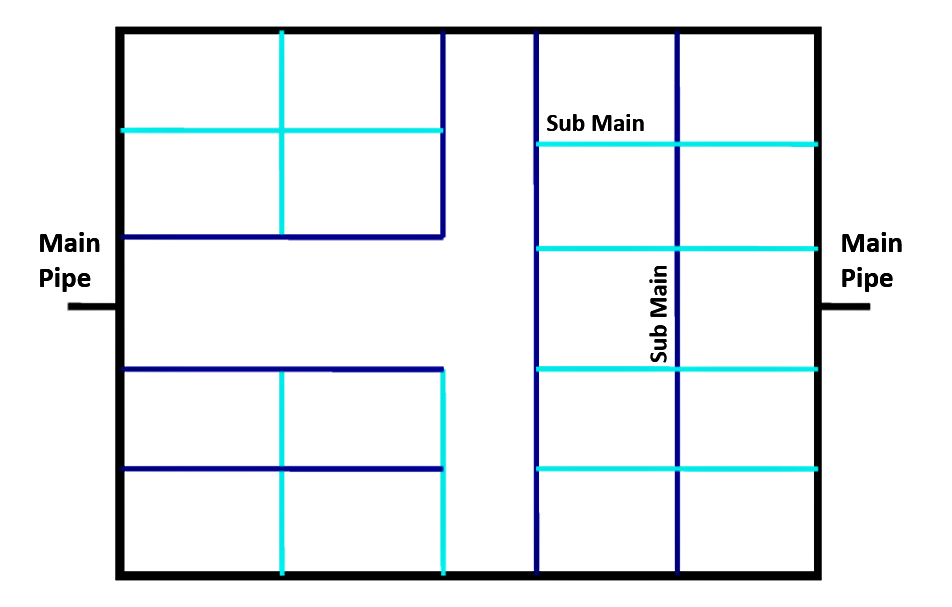

3. Circular or ring distribution system

|

Description: In a circular or ring system, the supply main forms a ring around the distribution area. The branches are connected cross-wise to the mains and also to each other. This system is most reliable for a town with well-planned streets and roads. The advantages and disadvantages of this system are the same as those of the gridiron system. However, in case of fire, a larger quantity of water is available, and the length of the distribution main is much higher. |

|

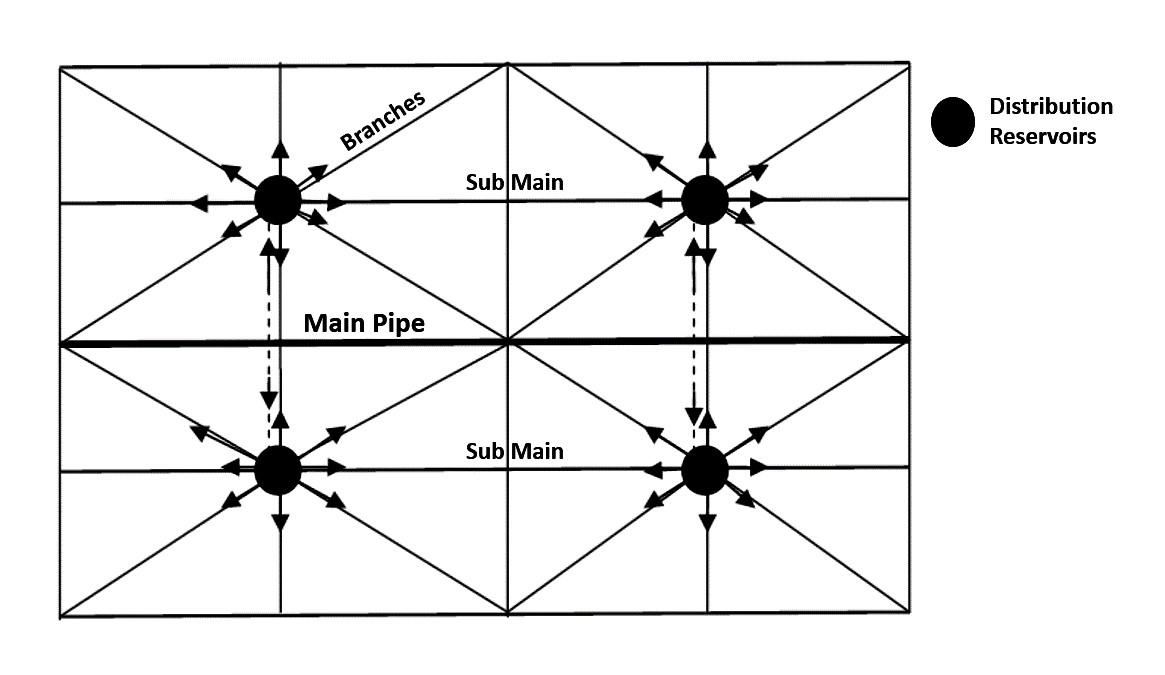

4. Radial distribution system

|

Description: In this system, the whole area is divided into a number of distribution districts. Each district has a centrally located distribution reservoir (elevated) from where distribution pipes run radially towards the periphery of the distribution district. This system provides swift service, without much loss of head. The design calculations are much simpler. |

|

Components and dimensioning of a network

Components

Adopted from HICKEY (2008)

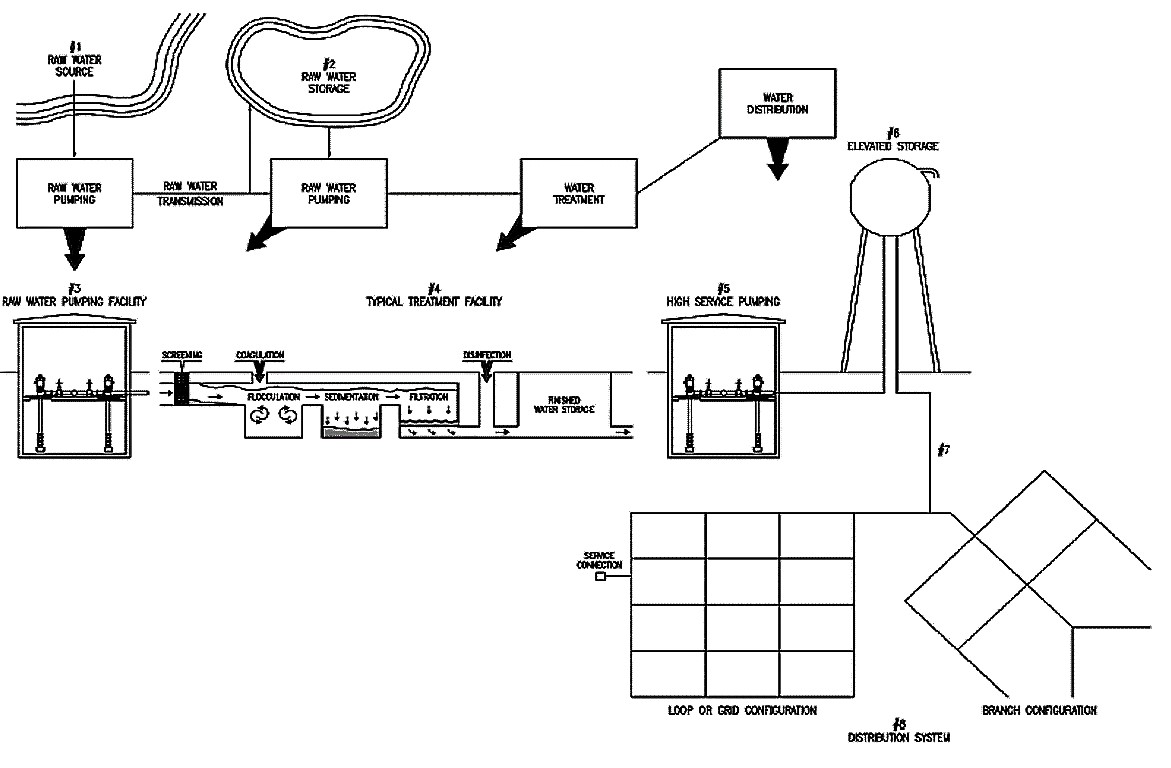

Water source: At the beginning of every water distribution network, there must be a raw water source (nr.1) such as a lake, river or groundwater source. To provide enough water for the network the water can be stored in a reservoir (nr.2).

Raw water pumping: These pumps (nr.3) transport water from the source to the raw water storage facility (see also mechanised pumping or manual pumping). The water is filtered before being injected into the network in order to prevent corrosion.

Treatment (purification): At one stage of the distribution, the water is purified in order to reach the standard quality (see also water purification) (nr.4). In the illustration above (nr.4) this is done in a centralised treatment plant by screening, coagulation-flocculation, sedimentation and filtration (e.g. membrane filtration). As a last step it is disinfected (e.g. chlorination or ozonation).

High service pumping: Pumping stations (nr. 5) may be needed to: pump water up to service areas that have higher elevations than other areas of a community. Fill gravity tanks that float on the water supply distribution system. When pumping stations are used to distribute water, and no water storage is provided, the pumps force water directly into the network.

Elevated storage: An extremely important element in a water distribution system is water storage (nr.6). System storage facilities have a far-reaching effect on a system’s ability to provide adequate consumer consumption during periods of high demand while meeting fire protection requirements. The two common storage methods are ground-level storage and elevated storage.

Piping/ distribution system: At the end of the system, water is distributed via pipes to the consumer, who has to pay for the used amount (see also water pricing).

Hydraulics

Adapted from AINSWORTH (2004)

The hydraulics of the network (adequate pressure and flow) is the main element of network dimensioning and design. Pressure occurs through gravity or pumps and is lost by the action of friction at the pipe walls. The pressure loss also depends on the water demand, pipe length, gradient and diameter. Several established empirical equations describe the pressure–flow relationship. These have been incorporated into network modelling software packages to facilitate their solution and use. When designing a piped system, the aim is to ensure that there is sufficient pressure at the point of supply to provide an adequate flow to the consumer. For example, in England and Wales, water companies are required to supply water to a single property at a minimum of 10 m head of pressure at the boundary stop tap with a flow rate of 9 l/min. This minimum pressure increases as the number of properties supplied through a single service pipe increases. For the purpose of maintaining microbial quality, it is important to minimise transit times and avoid low flows and pressures. These requirements have to be balanced against the practicalities of supplying water according to the location of consumers and where pipes can be laid.

Cost considerations

Construction costs depend on the chosen system (e.g. lower costs for a dead end system), on the used pipes (see water distribution pipes) and on the regional conditions (excavation depth (see trenches), soil conditions, equipment, etc.).

Gravity flow network are cheaper, because they require less pumping.

Health aspects

The safety of drinking water depends on a number of factors, including quality of the water source, effectiveness of water purification and integrity of the whole distribution system that transports the water to consumers. At every stage in the production and delivery of drinking water, hazards can potentially compromise the quality of the water. Piped distribution systems may be less vulnerable to contamination than open surface-water catchments; however, if piped systems become contaminated (see also preventing recontamination), there may be no treatment processes to reduce risks from the introduced hazards (AINSWORTH 2004).

A leaking distribution system increases the likelihood of safe water leaving the source or treatment facility becoming contaminated before reaching the consumer. The distribution system must be designed, managed and maintained to present a minimal level of leakage and be continuously under internal pipe pressure greater than the external hydrostatic pressure. This will ensure delivery of water with reduced losses due to leaks, and minimisation of excess growth of pathogenic microorganisms. A certain level of free residual chlorine or chloramine disinfectant will reduce the risks of recontamination within the distribution system (read more about microbiological growth in plumbing in WHO 2006, chapter 3.1.4). Inflows of contaminated water during distribution are major sources of waterborne pathogens and contaminants (WHO 2006).

In case the appropriate quality of the supplied water cannot be guaranteed, proper household water treatment and safe storage become necessary.

Operation and maintenance

Adapted from GONU (2009)

After installation

After a piped system is installed it should be pressure tested, flushed to remove all dirt and foreign matter and disinfected (e.g. chlorination). Following disinfection the chlorinated water should be flushed to waste with potable water. Microbiological tests are required before the main is put into service.

Preventive maintenance of appurtenances

Preventive maintenance of valves involves location, inspection and operation. Location of the valve box is confirmed by checking the measurements given on the map. Next, the valve box cover is removed and the interior inspected with a flashlight. Finally, the valve is fully closed, and the number of turns required to close it is recorded. The tightness of closure is checked through listening with a leak detector (read also the factsheet on leakage control). To avoid damage/failure of the stem, the applied torque using a power turning should not exceed the recommended limit specified by the manufacturer.

Common defects requiring repair are broken stems, need for packing, and internal incrustation. Repair of a valve is a difficult task requiring isolation of that section of the pipe network, excavation, and removal of the valve. Either the damaged valve can be repaired and replaced or, if the overall conditions are good, new parts that need to be changed can be installed on site.

If there is enough infrastructure and knowledge available to install a piped network, it is a great advantage for every community. It is a convenient access to fresh water. The chosen system depends on local conditions (read above). An important part of a network is the piping, read more about it here.

Safe Piped Water: Managing Microbial Water Quality in Piped Distribution

This review looks at the factors affecting the presence and growth of microorganisms in piped networks, and the practices of water supply organisations that can directly or indirectly influence their presence and growth. This review is intended for policymakers but it is also relevant to engineers and scientists responsible for water supply planning, operations and monitoring.

AINSWORTH, R. (2004): Safe Piped Water: Managing Microbial Water Quality in Piped Distribution. Geneva: World Health Organization (WHO) URL [Accessed: 13.05.2019]Guidelines for Water Loss Reduction

These guidelines aim to impart knowledge about water loss reduction to decision-makers and stakeholders at the national level and to the management team, planning and design department and operating staff at local water utilities in developing and transition countries. The guidelines are accompanied by capacity development materials as well as the implementation of pilot projects in order to transfer know-how and implement state-of-the art pressure management (PM) technology in practice.

GIZ (2011): Guidelines for Water Loss Reduction. A Focus on Pressure Management. Eschborn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 13.05.2019]Technical Guidelines for the Construction and Management of Drinking Water Distribution Networks

These guidelines were developed for the construction and management of rural water supply and sanitation facilities. It is a collection of global and national good practices in water and sanitation that have been collated. These simple guidelines are primarily intended as a reference for field staff and practitioners in the water and sanitation sector challenged by situations and conditions in the field.

GONU (2009): Technical Guidelines for the Construction and Management of Drinking Water Distribution Networks. Khartoum: Government of National Unity (GONU) URL [Accessed: 13.05.2019]Siedlungswasserwirtschaft

Water Supply Systems and Evaluation Methods. Volume II: Water Supply Evaluation Methods

A document on water supply evaluation methods.

HICKEY, H.E. (2008): Water Supply Systems and Evaluation Methods. Volume II: Water Supply Evaluation Methods. Emmitsburg: U.S. Fire Administration URL [Accessed: 13.05.2019]Water Distribution Systems

Health Aspects of Plumbing

This publication describes the processes involved in the design, installation and maintenance of effective plumbing systems. It recommends a number of plumbing system designs and installation specifications.

WHO (2006): Health Aspects of Plumbing. Geneva: World Health Organisation (WHO) URL [Accessed: 24.03.2011]In the Pipeline: Water for the Poor Investing in small piped Water Networks

This tool kit is intended to be used as a guide for governments, development agencies, utilities, and civil society in putting up or implementing piped water projects using the Small Piped Water Network concept for urban poor or rural communities without access to piped water systems.

ADB (2008): In the Pipeline: Water for the Poor Investing in small piped Water Networks. Mandaluyong City: Asian Development Bank (ADB) URL [Accessed: 15.05.2012]Safe Piped Water: Managing Microbial Water Quality in Piped Distribution

This review looks at the factors affecting the presence and growth of microorganisms in piped networks, and the practices of water supply organisations that can directly or indirectly influence their presence and growth. This review is intended for policymakers but it is also relevant to engineers and scientists responsible for water supply planning, operations and monitoring.

AINSWORTH, R. (2004): Safe Piped Water: Managing Microbial Water Quality in Piped Distribution. Geneva: World Health Organization (WHO) URL [Accessed: 13.05.2019]Guidelines for Water Loss Reduction

These guidelines aim to impart knowledge about water loss reduction to decision-makers and stakeholders at the national level and to the management team, planning and design department and operating staff at local water utilities in developing and transition countries. The guidelines are accompanied by capacity development materials as well as the implementation of pilot projects in order to transfer know-how and implement state-of-the art pressure management (PM) technology in practice.

GIZ (2011): Guidelines for Water Loss Reduction. A Focus on Pressure Management. Eschborn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 13.05.2019]Technical Guidelines for the Construction and Management of Drinking Water Distribution Networks

These guidelines were developed for the construction and management of rural water supply and sanitation facilities. It is a collection of global and national good practices in water and sanitation that have been collated. These simple guidelines are primarily intended as a reference for field staff and practitioners in the water and sanitation sector challenged by situations and conditions in the field.

GONU (2009): Technical Guidelines for the Construction and Management of Drinking Water Distribution Networks. Khartoum: Government of National Unity (GONU) URL [Accessed: 13.05.2019]Water Supply Systems and Evaluation Methods. Volume I: Water Supply System Concepts

A document on water supply evaluation methods.

HICKEY, H.E. (2008): Water Supply Systems and Evaluation Methods. Volume I: Water Supply System Concepts. Emmitsburg: U.S. Fire Administration URL [Accessed: 13.05.2019]Water Supply Systems and Evaluation Methods. Volume II: Water Supply Evaluation Methods

A document on water supply evaluation methods.

HICKEY, H.E. (2008): Water Supply Systems and Evaluation Methods. Volume II: Water Supply Evaluation Methods. Emmitsburg: U.S. Fire Administration URL [Accessed: 13.05.2019]Health Aspects of Plumbing

This publication describes the processes involved in the design, installation and maintenance of effective plumbing systems. It recommends a number of plumbing system designs and installation specifications.

WHO (2006): Health Aspects of Plumbing. Geneva: World Health Organisation (WHO) URL [Accessed: 24.03.2011]Lecture 37 Water Distribution Networks

A one-hour lecture about water and wastewater engineering (Department of Civil Engineering, IIT Madras).