Executive Summary

A sustainable sanitation system has to manage all waste products and by-products generated. It consists of a suitable combination of appropriate technologies for the capture, storage, transport, treatment and disposal or safe reuse of human excreta and wastewater. Reuse activities within a sustainable sanitation system may focus on nutrients, water, energy or organic matter contained in the excreta and wastewater.

The long-term success of any sanitation system depends on social acceptance and awareness for the benefits, support from politically influential actors and costs being covered by a suitable operator and business models.

See our practical experiences, lessons learned and recommendations below.

Why you should care

If you cannot afford, operate and maintain it, do not build it.

What really matters: Lessons learned & recommendations

Holistic and city-wide planning addressing safe collection, treatment and reuse/disposal of all excreta and wastewater

Making profound decisions that consider future developments requires a combination of integrated planning, adequate development strategies and suitable financing schemes for wastewater infrastructures. Therefore, before deciding on any sanitation intervention, solutions have to be well thought through for the entire area (area boundaries) in terms of a ‘Sanitation Master Plan’. Once this is finalised, selective measures in line with the long-term sanitation plan can be picked and implemented (incremental, stage-wise approach).

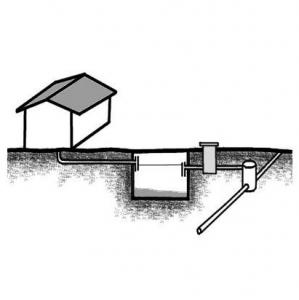

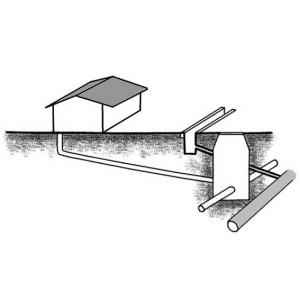

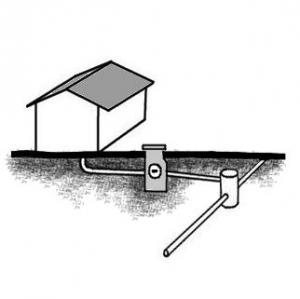

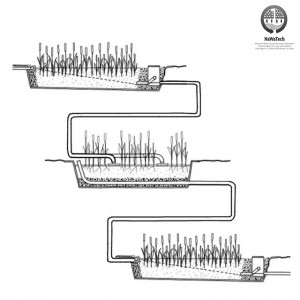

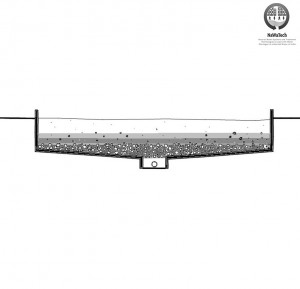

In the process of sanitation planning for Azraq, different options – ranging from completely decentralised treatment via semi-centralised to centralised treatment - were considered. Doing so helped to narrow down options for wastewater management and allowed for evidence- and fact-based decisions in choosing the preferred implementation scenario: A so-called hybrid scenario consisting of the step-by-step implementation of a centralised wastewater and faecal sludge management plant receiving faecal sludge through tankers (for the time being) is implemented. Provision of an underground sewer system (and continuation of desludging services wherever linking households to the sewer is not feasible) is intended at a later stage.

Minimise use of services of external consultants.

During the project inception phase, services of both national and international external consultants were used to independently or in support of the project consortium perform a wide range of studies such as Co-Funding Strategy, Cost-Benefit Analysis, Innovation into Sanitation, etc. Due to the involvement of many consultants, the individual assignments subcontracted were rather small and overall coordination became more complex as number of consultants increased. Even well-known consulting companies had very small contracts (sometimes a few working days only) and therefore showed little interest in going the extra mile. Furthermore, it became evident that adopting a piecemeal approach in the distribution of the overall workload led to overlaps in consultants’ assignments and high travel costs. In retrospect, we could have executed many of the subcontracted tasks ourselves. In our experience, a project inception phase should be done with a rather small, diverse and interdisciplinary team benefitting from ad hoc assistance/support by external experts. We learned that it is advisable to consider a small but separate ‘emergency budget’ for unforeseen external expert support needs resulting from activities performed within the inception phase. This allows for a certain flexibility and offers room for innovation. During the project inception phase a list of (inter)national experts for the detailed planning during the project’s main phase shall be compiled.

Discard unrealistic approaches quickly.

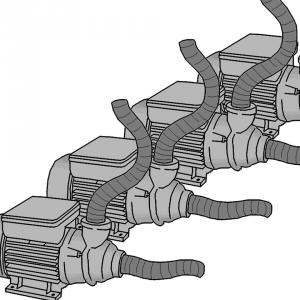

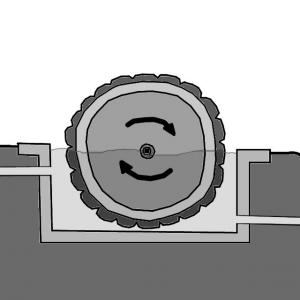

While developing a sustainable sanitation project, new and innovative approaches must be followed. We, for example, looked into and considered vacuum sewers for the transportation of wastewater. One reason for doing so was the basaltic rock conditions of the soil within our target area and the high expenses expected for excavation in rock. However, vacuum sewers also come with certain disadvantages such as relatively high capital costs, the need for energy to create a permanent vacuum, etc. Rather than quickly discarding the vacuum sewer as an unrealistic approach (in the local context) for the transport of wastewater, we followed up on it for quite some time, which tied up resources. We recommend carrying out “reality checks” (that is preliminary checks) for local feasibility of technological options in order to not waste resources on pursuing unrealistic approaches.

Practical experience and expertise in the implementation of similar projects.

Being a young team, we lacked process know-how, first-hand practical experience and expertise in terms of implementation of complex sanitation projects. A senior expert with many years of practical experience and top-class technical expertise could have provided orientation and the necessary support to efficiently manage and implement from the get-go.

Intensively and consistently involving national specialists and experts in the sanitation planning approach.

Consider from the very beginning that stakeholder engagement is time consuming and needs close follow-up work to meet the expectations of your stakeholders and maintain the positive, supportive mood of relevant stakeholders towards the project. This means allowing enough time and resources for regular meetings with local and national specialists, experts and decision makers in the design and planning phase to ensure broad acceptance of and support for the proposed sanitation concept. In addition, it is important to adapt to local working practises (emails vs. personal meetings, for example) to progress as planned within the project.

Commissioning general planer.

Like in the inception phase, we involved many (inter)national experts in the detailed planning during the main project phase: process planning, construction engineering, planning of the access road, electrical planning, etc. Instead of again adopting a piecemeal approach, hiring a trustworthy general planner would have drastically reduced coordination efforts between the individual consultants/experts on our end.

Checklist

- Have you performed a holistic and city-wide planning addressing safe collection, treatment and reuse/disposal of all excreta and wastewater?

- Have you assigned a diverse and interdisciplinary project team allowing you to minimise the use of services of external consultants while implementing the project inception phase?

- Did you perform “reality checks” (that is preliminary checks) for local feasibility of technological options to not waste resources in pursuing unrealistic approaches?

- Do you have a senior expert with many years of practical experience and top-class technical expertise to provide orientation and the necessary support to less experienced staff members?

- Have you considered enough time and resources for regular meetings with local and national specialists, experts and decision makers in the design and planning phase to ensure broad acceptance for the proposed treatment system?

- Have you considered commissioning a general planner?