Executive Summary

Horizonal Flow (HF) wetlands are secondary treatment facilities for household, municipal or industrial wastewater, and can also be used as a tertiary treatment system for polishing effluent. HFs are composed of one or more planted filter beds, filled with proper inert material, through which pre-treated wastewater flows horizontally. Wastewater flows below the surface, maintaining continuous saturated conditions. HFs are planted with emergent aquatic macrophytes, which provide a suitable environment for microbiological attachment, aerobic biofilm growth and oxygen transfer to the root zone. Organic matter and suspended solids are mainly removed by filtration and microbiological degradation in prevalently anoxic conditions.

Input/Output/Removal of

| Input: | Degreased, screened sewage | Industrial wastewater |

| Output: | Secondary treated effluent | Other: harvested plants |

| Removal of... | Ntot | Organic compunds/COD/BOD5/TOC | Pathogens |

Removal of...

| Total suspended solids (TSS) |

| Ntot |

| Organic compounds / COD / BOD5 / TOC |

| Pathogens |

Input: |

| Degreased, screened sewage |

| Industrial Wastewater |

Output: |

| Secondary treated effluent |

| Other: harvested plants |

Design Considerations

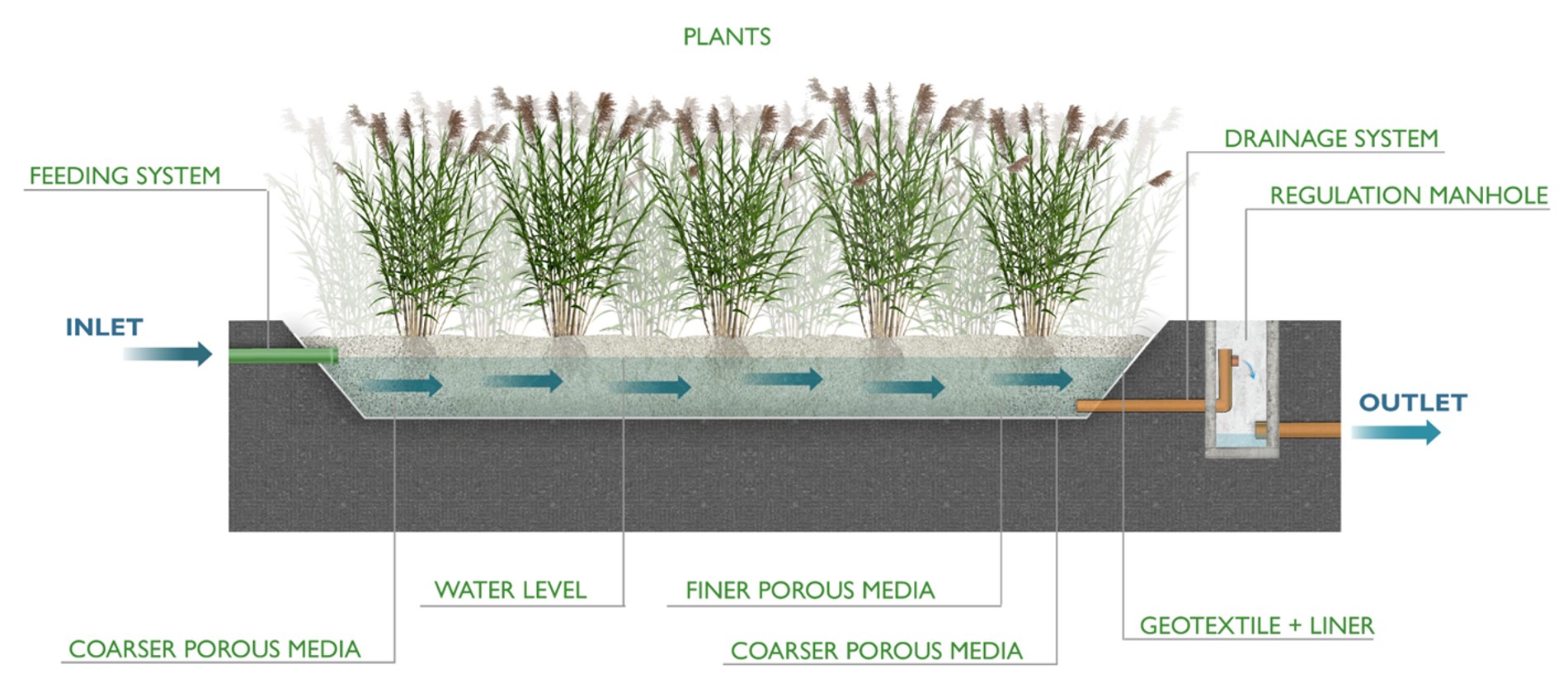

HF wetlands typically consist of the following main components illustrated schematically in Fig.1 figure below:

- Plastic liner

- Filter layer: fine gravel (average diameter 10 - 20 mm)

- Vegetation (Phragmites)

- Drainage system

- Distribution system

Fig 1: Schematic illustration of a HF wetland. Source: Own illustration (2020)

The water in HF wetlands is treated by a combination of biological and physical processes such as adsorption, precipitation, filtration, nitrification, denitrification, decomposition, etc. (HOFFMANN et al. 2010). In HF systems, the wastewater is fed at the inlet zone, usually by gravity, and flows horizontally through the porous filter medium, remaining under the surface of the bed and without any contact with the atmosphere, until it reaches the outlet zone. To avoid clogging of the wetland, pre-treatment is necessary to separate solid materials (see for example Settler), grease, or oils from the liquid.

A plastic liner waterproofs the basins and avoids soil contamination. The depth of filter beds, which are planted with aquatic plants, is normally 60 - 80 centimetre (cm). The bottom slope should be 0.5 - 1.0% from inlet to outlet to achieve good drainage (MOREL and DIENER 2006) and the filter length no longer than 25 - 30 metres. The hydraulic retention time and the specific surface area depend on the targeted treatment results with normally around 2 - 5 days and about 2 - 5 square metres per person equivalent (m²/PE) if the effluent is to be discharged in fresh water. The hydraulic loading should be 60 - 80 millimetre per day (mm/d) for greywater (RIDDERSTOLPE 2004, MOREL and DIENER 2006), and 30 - 60 mm/d for mixed wastewater. The reduction of BOD (Biological Oxygen Demand) is about 80 - 90%, for Total Suspended Solids (TSS) 80 - 95%, for Total Nitrogen (TN) up to 60% and for Faecal Coliforms (FC) about 2 - 4 log.

Suitability

HF wetlands can adapt well to different climates. As warmer temperatures allow for faster biological activity, year-round warm climate (typically found in tropical or hot climates) can improve the overall efficiency of the system compared to cold climates. Nevertheless, if properly designed and operated, HF wetlands can also be used in mountainous regions with cold weather periods or even frost.

HFs are a suitable option for small and medium communities in peri-urban areas. Application in urban areas for various purposes - also in combination with other simple technologies such as anaerobic treatments - is also possible, i.e. greywater/mixed wastewater treatment and local reuse for groups of buildings, campuses, public areas, etc.

HFs can be set-up in a way that no pumping, respectively, electricity is required for operation, which can lower the operational costs, simplify operation and maintenance (O&M) and make this technology suitable for developing countries.

The higher space requirement (2 - 5 m2/PE) compared to other technologies limits the application of this technology mainly to areas with low population density or to areas where space availability is not a limiting factor. The use of anaerobic primary treatment plants with high efficiency in removing solids and organic matter (e.g. Anaerobic Baffled Reactors, Anaerobic Filters or similar anaerobic systems) as as pre-treatment step can significantly reduce the space requirement of HF wetlands; furthermore, anaerobic primary treatment options can work efficiently in colder climates if properly designed and operated.

Heavy rainfall like during monsoon periods must be taken into account for the hydraulic calculations; however, rainfall per se does not significantly affect the performance of HFs, because they are well adaptable to the oscillation of the hydraulic and organic flow.

Operation and Maintenance

O&M requirements for HF wetlands are relatively simple and can be conducted by unskilled labour after adequate training (no handling of high-tech appliances or chemical additives involved). This allows that also community organisations or even private individuals may manage such a system.

Maintenance includes periodic control and emptying of sludge (see also Sludge Drying Reed Beds for Faecal Sludge Treatment) and scum in the primary treatment system; plant harvesting (usable as biomass for energy production, or as building material for thermal and acoustic insulation); checking the perfect functioning of the distribution system, ensuring that no clogging occurs in the bed and sampling of the discharged water. With time the gravel will become clogged and may have to be replaced or regenerated every 10 - 20 or more years. The water level should be maintained 5 - 10 cm below the surface of the gravel to avoid odours and mosquito diffusion.

Experiences in India

HF wetland systems, sometimes simply called planted gravel filter, are quite common in India as they are part of the so-called DEWATS (Decentralized Wastewater Treatment Systems) approach (https://cddindia.org; www.borda.org). Below are some examples of functional systems:

Ekant Park in Bhopal: a HF demonstration unit was constructed by the Environmental Planning and Coordination Organization (EPCO) to treat 70 m3/day: a septic tank of 35 m3 is installed before a HF system of 700 m2 filled with gravel and planted with Phragmites karka. The monitoring results (April 2002 - Sept 2003) show good removal for COD (77%), TSS (79%), Coliform bacteria (99%) (VIPAT et al. 2008).

Ujjain Charitable Trust Hospital and Research Centre (Madhya Pradesh): a HF system filled with gravel 10 - 25 mm and planted with Typha latifolia treats 8 m3/day with a surface of 80 m2 and showed during the monitoring good removal for BOD (75%), TSS (78%), Ammonia - NH4 (68%) (DIWAN et al. 2008), with a hydraulic retention time of less than 2 days.

Ravindra Nagar Township Ujjain (Madhya Pradesh): a HF system filled with zeolite 3 - 9 mm was monitored from 2006 to 2008 (BILLORE et al. 2008) showing an ammonia removal of about 70%.

Ujjain, Central India, a small community of residential areas: pilot study where the performance of a HF system of 42 m2 planted with Phragmites karka was investigated: in a period of five months from the implementation of this HF system average removal efficiencies of 78% for NH4-N, TSS; 58 - 65% for Phosphorus (P), BOD and Total Kjeldahl Nitrogen (TKN) (BILLORE et al. 1999) were recorded.

Experiences Globally

The use of HF wetlands began started in Germany based on research by Käthe Seidel in the 1960s (and by Reinhold Kickuth in the 1970s). And for a long time, HF systems were the most widespread wetland technology worldwide, as reported by VYMAZAL and KRÖPFELOVÁ (2008).

Ondřejov, Czech Republic: the oldest HF wetland in the Czech Republic, built in 1991, is still in operation. The wetland treats sewage from 360 persons in a single HF bed planted with common reed (Phragmites australis). The system consists of a grit chamber, an Imhoff Tank and a single 806 m² HF bed filled with gravel (3 - 15 mm). The average measured flow was 56.3 m³/d resulting in a Hydraulic Loading Rate (HLR) of 70 mm/d. The average yearly removal efficiencies measured between 1991 and 2005 have been 93% for BOD5, 89% for COD (Chemical Oxyden Demand), 95% for TSS, 41% for NH4-N, 37% for TN (data until 2004 only), and 46% for Total Phosphorus (TP) (DOTRO et al. 2017).

Village of Sarra, Palestine: in this case, two problems were addressed: the scarcity of water and the improvement of wastewater quality. Between 2012 and 2013 a treatment system designed with a capacity of 4.300 people equivalents was implemented by IRIDRA SRL. The secondary treatment system, a HF wetland in combination with a Vertical Flow (VF) wetland, has a total area of 4.500 m2. The entire system includes pre-treatment, primary treatment (Imhoff Tanks), an accumulation pond and wetlands for the treatment of sludge from the Imhoff Tanks, the construction costs amounted to Euros 596.000.

Horizontal Subsurface Flow Gravel Bed Constructed Wetland with Phragmites Karka in Central India

Removal of Ammonium-N from Domestic Wastewater by Using Zeolite Bed Through Constructed Wetland, India

Subsurface Flow Constructed Wetland in a Tropical Climate: A Performance Study from Ujjain, India

Technology Review of Constructed Wetlands - Subsurface Flow Constructed Wetlands for Greywater and Domestic Wastewater Treatment

Greywater Management in Low and Middle-Income Countries - Review of Different Treatment Systems for Households or Neighbourhoods

Efficacy of Rootzone Technology for Treatment of Domestic Wastewater

Wastewater Treatment in Constructed Wetlands with Horizontal Sub-Surface Flow

Compendium of Natural Water Systems and Treatment Technologies to cope with Water Shortages in Urbanised Areas in India

The Compendium of NaWaTech Technologies presents a list of solutions (appropriate water and wastewater technologies) to treat and recover water suitable to be used in urbanised areas in India. It was created with the contribution of several experts in the sector and it is intended as a reference for water professionals in charge of planning, designing, and implementing sustainable water systems in the Indian urban scenario, based on a decentralised approach. It includes design principles, operation and maintenance requirements and cost considerations.

BARRETO DILLON, L., DOYLE, L., LANGERGRABER, G., SATISH, S. and POPHALI, G. (2013): Compendium of Natural Water Systems and Treatment Technologies to cope with Water Shortages in Urbanised Areas in India. Berlin: EPUBLI GMBH. URL [Accessed: 03.05.2023] PDFTreatment Wetlands. Biological Wastewater Treatment Series, Volume 7

The Volume 7 of the Biological Wastewater Treatment Series describes various typologies of treatment wetlands, with their application, design indications, operation and management, design examples, and case studies.

DOTRO, G., LANGERGRABER, G., MOLLE, P., NIVALA, J., PUIGAGUT, J., STEIN, O. and VON SPERLING, M. (2017): Treatment Wetlands. Biological Wastewater Treatment Series, Volume 7. London: International Water Association (IWA) publishing. URL [Accessed: 03.05.2023] PDFCompendium of Sanitation Systems and Technologies. 2nd Revised Edition

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E., ULRICH L., LÜTHI, C., REYMOND P. and ZURBRÜGG C. (2014): Compendium of Sanitation Systems and Technologies. 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 03.05.2023] PDFIRIDRA: Horizontal Flow Wetland (HFW)

This presentation offers a broader view on Horizontal Flow Wetland (HFW)

BRESCIANI, R. (2023): IRIDRA: Horizontal Flow Wetland (HFW). Training Program on Sustainable Natural and Advance Technologies and Business Partnerships for Water & Wastewater Treatment, Monitoring and Safe Water Reuse in India . PDFTraining Session Plan - Horizontal Flow Wetland

Training session plan on Horizontal Flow Wetland (HWF)

BRESCIANI, R. and MASI, F. (2023): Training Session Plan - Horizontal Flow Wetland. Training Program on Sustainable Natural and Advance Technologies and Business Partnerships for Water & Wastewater Treatment, Monitoring and Safe Water Reuse in India . PDFNBS List

The website includes a list of Nature-Based-Solutions (NBS), including HFs , FRB, and Aerated Engineered Wetlands; for each NBS, additional information is provided as well as downloadable factsheets, including general description of the particular NBS, basic technical information on design and performance, description of co-benefits, and project examples.

https://snapp.icra.cat/nbslist [Accessed: 26.07.2021]Akvopedia

Website describing the main characteristic of horizontal flow constructed wetlands.

https://akvopedia.org/wiki/Horizontal_Subsurface_Flow_Constructed_Wetland [Accessed: 03.05.2023]