Executive Summary

Centralised drinking water treatment plants treat large amounts of water from many households in one single spot and consequently most often require more operation and maintenance and the construction of a water distribution system. Semi-centralised drinking water treatment plants are middle-scaled units e.g. on community level. These systems are most often designed to remove several types of contaminants from anthropogenic or natural origin: suspended and dissolved solids, ions (metals, fluorine, phosphates, nitrates), organic compounds (organic micropollutants, natural organic matter), and microorganisms (bacteria, viruses). As there is no water treatment method able to remove all these contaminants in one step semi-centralised and centralised treatment often needs multistep plants, which combine several techniques to purify water. Here a general overview of plant set-up for drinking water production is given.

| In | Out |

|---|---|

Drinking Water |

Introduction

Drinking water treatment plants involve several consecutive processes, which remove solids, organic and inorganic pollutants, some metals and pathogenic microorganisms. The treatment plant set-up should be designed to take into account the quality of water being treated. In general, water treatment can be divided into: primary treatment to remove solids; secondary treatment to remove organic compounds as well as nitrogen and phosphorous; and tertiary treatment for disinfection.

Different sizes of treatment plants exist like centralised plants for big cities requiring a developed distribution system and semi-centralised plants adapted to provide drinking water to smaller communities at the point of use (POU).

Drinking water treatment plants

(Adapted from EPA 1999)

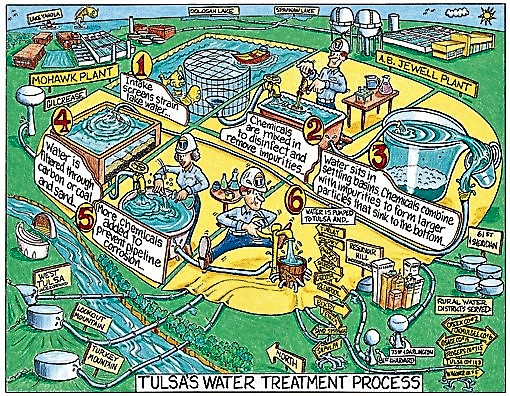

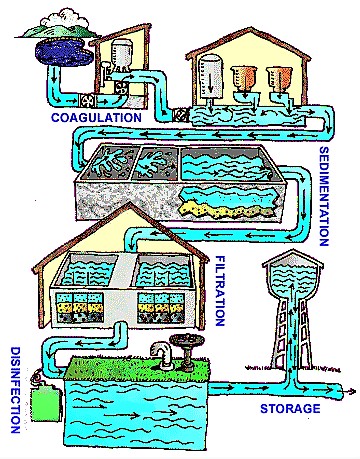

There is no precise method for treating surface water because of the various qualities of water that exists. Groundwater typically requires less treatment than water from lakes, rivers and the sea. Nevertheless, a series of conventional processes can be identified; they are presented in the figures below.

In general the treatment of fresh water involves the following key steps:

Primary Steps

- Aeration: The water is mixed to liberate dissolved gases and to suspend particles in the water column. Sometimes a pre-oxidation step is also performed at this stage.

- Coagulation-Flocculation: In this step coagulants are added to remove the suspended particles (clay, organic material, metals, microorganisms), which stick to the coagulants forming heavy particles.

- Sedimentation: The heavy particles (flocs) settle to the bottom leading to clear water.

Secondary Step

- Filtration: The water is run through a series of filters, which trap and remove particles still remaining in the water column. Typically, slow or rapid sand filtration and more recently membranes or reverse osmosis are used to accomplish this task. Due to growing concerns regarding micro-pollutants, additional treatments such as advanced oxidation processes, activated carbon adsorption alone or combined with ozonation or H2O2 are sometimes used to remove these trace organic compounds.

Tertiary Step

- Disinfection: The water is now largely free of particles, organics and microorganism and is now treated to destroy any remaining disease-causing pathogens. This is commonly done with chlorination, ozonation, hydrogen peroxide, or UV radiation (similar to the point of use UV tubes). The water is then sent to the pumping station for distribution to homes and businesses. Chlorination is the most widely used disinfection method because it permits maintaining residual chlorine at a level efficient enough to guarantee the absence of microorganism until the water has reached its point of use.

When drinking water is produced from the sea, the water is desalinated by electrolysis or membranes such as reverse osmosis or by a solar process desalination.

Operation and maintenance

(Adapted from CWEA 2004)

Drinking water treatment plant operation and maintenance includes the following tasks:

- Operate and adjust equipment controls to purify and clarify water.

- Inspect equipment and monitor operating conditions, meters, and gauges to determine load requirements and detect malfunctions.

- Add chemicals, such as ammonia, chlorine, and lime, to purify and disinfect water and other chemicals, such as ferric chloride, peroxide, and polymers, to enhance water treatment.

- Collect and test water samples, using test equipment.

- Record operational and laboratory data, observations of processes, and meter and gauge readings on specified forms.

- Clean and maintain tanks, basins and filter beds, using hand tools and power tools.

- Maintain, repair, and lubricate equipment, using hand tools and power tools.

Many of these tasks can be automated in modern treatment plants but trained operators and engineers are still required to control and maintain the system. Moreover, operation of the treatments also requires a significant amount of chemicals, which might not be available in little industrialised or remote areas.

Required energy input is significant. In Switzerland, required energy input for treatment and distribution of drinking water, including abstraction, is relatively low (around 0.4kWh/m3) due to the excellent quality of groundwater. In case of polluted or seawater treatment in semi-centralised plants, the required input is higher (around 1-2 kWh/m3). Smaller drinking water treatment plants may be installed at semi-centralised level or point of use in order to minimise energy requirements for distribution.

Average costs of water treatment plants

The cost of high quality municipal drinking water including transport is between less than 1 $/m3 in the US and more than 2 $/m3 in Denmark and Germany (CLARK 2007). The cost of drinking water from semi-centralised treatment plants operating in developing countries depends on water source quality and capacity. In the case of seawater and polluted sources it is typically around 1-2 $/m3. An important initial investment is required to build the treatment plant, which should be designed properly taking into account water composition to minimise the costs.

Alternative: ecosystems as water suppliers

Conservation or restoration of ecosystems is a good strategy to simplify and reduce the costs induced by drinking water treatment plants. If the water body has a good quality, drinking water can be obtained without any treatment. Therefore, wastewater treatment and integrated water resource management are crucier treatmenal to sustainable drinking water supply.

Another interesting alternative to improve the quality of influent water and lower the costs of treatment is bank filtration. This is done for instance in Basel, New York or Vienna.

In the city of Basel (166,000 inhabitants), the quantity of groundwater is insufficient to meet the city’s needs. Some 120,000 m3 of water per day are treated from the River Rhine through a mechanical filtration installation equipped with a quartz sand filter to remove the sediment. It then runs into small channels through a forest where it is infiltrated into the subsoil and thereby cleaned before reaching the groundwater (VERMONT 2004).

The natural systems of upstate New York's Catskill/Delaware watershed provide most of the City's drinking water. Rather than spending $8 billion on a water treatment facility in New York City, New York State opted to spend $1 billion to restore the watershed that provides the City’s drinking water (ESA 2012).

At a glance

| Working principle | Combines several processes (e.g. aeration, coagulation-flocculation, filtration, disinfection) to remove a wide variety of contaminants present in water. |

| Capacity/adequacy | Sophisticated combination of water treatment processes. Skilled labour required to guarantee the performance of each process. |

| Performance | Efficient for all kinds of water when treatment plants are adequately designed and set up. |

| Costs | Relatively high implementation and operation costs because of high inputs of labour, chemicals and electricity. |

| Self-help compatibility | The incoming water and treated water quality has to be monitored to optimise each step of the plant. |

| O&M | Continuous operation and maintenance staff is required. |

| Reliability | Highly reliable if the treatment plant is well maintained. |

| Main strength | Very efficient for any kind of water. |

| Main weakness | The whole system has to be controlled on a regular basis to be efficient, hence the system is sophisticated and requires skilled labour, energy, technical equipment and chemicals. |

Centralised drinking water treatment plants are useful when water is supplied from a source containing natural or anthropogenic contaminants such as lakes, rivers, seas or groundwater. Many different types of raw water can be purified in treatment plants as processes are designed for each case considering water quality and desired capacity.

The treatment plants need to be maintained by skilled labour to regularly control water quality and optimise processes.

Smaller drinking water treatment plants may be installed at semi-centralised level or point of use in order to minimise energy requirements for distribution.

Water Prices Rising Worldwide

Drinking Water and Wastewater Treatment Plant and Distribution System Operators

Drinking Water Treatment

Water Treatment Cycle

Water Purification: An Essential Ecosystem Service

This factsheet describes natural water purification by ecosystems. How to maintain the service of purification by conservation or restoration of the ecosystem is also briefly discussed.

ESA (2012): Water Purification: An Essential Ecosystem Service . [Accessed: 03.02.2012] PDFWater Treatment Process in the City of Tulsa

National Report of Switzerland on the Role of Ecosystems as Water Suppliers

Compendium of Sanitation Systems and Technologies (Arabic)

This is the Arabic version of the Compendium of Sanitation Systems and Technologies. The Compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. SCHERTENLEIB, R. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies (Arabic). 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) PDFTechnologies for Water and Wastewater Treatment

This article presents a review of the technologies and processes which are used for water and wastewater treatment in order to remove the various constituents of the polluting load: solids organic carbon, nutrients, inorganic salts and metals, pathogens. A second part describes the advanced processes to reuse treated municipal effluents in agriculture and industries and the main technologies used for desalination.

BOARI, G. ; MANCINI, I.M. ; TRULLI, E. (1997): Technologies for Water and Wastewater Treatment. In: Séminaires Méditerranéens: Volume 31 , 261-287. URL [Accessed: 22.05.2019]Water Purification: An Essential Ecosystem Service

This factsheet describes natural water purification by ecosystems. How to maintain the service of purification by conservation or restoration of the ecosystem is also briefly discussed.

ESA (2012): Water Purification: An Essential Ecosystem Service . [Accessed: 03.02.2012] PDFWater Treatment Plants Residuals Management

Water treatment plants produce a wide variety of waste products as well as safe drinking water. These residuals may be organic and inorganic compounds of liquid, solid, and gaseous form depending on the source of raw water and the type of treatment processes, commonly, coagulation/filtration, precipitate softening plant, membrane separation, ion exchange, and granular activated carbon.

TECHBRIEF (1998): Water Treatment Plants Residuals Management. In: National Drinking Water Clearinghouse: URL [Accessed: 26.11.2011]Evaluation of a Wastewater Treatment Technology for Water Reuse

This paper presents the lab scale wastewater treatment technology that can be used to obtain physicochemical and microbiological good quality water for reuse. This technology mainly consists of a combination of coagulation-flocculation, sedimentation and filtration stages and a final water ozonation. It was evaluated for different kinds of wastewaters: domestic, industrial, and fish processing plant.

VELIZ, E. ; LLANEZ, J.G. ; FERNANDEZ, L.A. ; BATALLER, M. ; HERNANDEZ, C. ; FERNANDEZ, I. ; ALVAREZ, C. (2005): Evaluation of a Wastewater Treatment Technology for Water Reuse. In: IOA 17th World Ozone Congress-Strasburg: , 1-10. PDFChapter 2. Removal Processes

This chapter considers various processes for the removal of microbes from water. In particular, it discusses: pre-treatment; coagulation, flocculation and sedimentation; ion exchange; granular filtration; slow sand filtration.

WHO (2004): Chapter 2. Removal Processes. In: LECHAVELLIER, M. and AU, K-K (eds). Water Treatment and Pathogen Control - Process Efficiency in Achieving Safe Drinking Water. London (UK): World Health Organisation (WHO). IWA Publishing, pp. 05-40. URL [Accessed: 22.05.2019]Advanced Technologies in Water and Wastewater Treatment

Three emerging treatment technologies, including membrane filtration, advanced oxidation processes (AOPs), and UV irradiation, hold great promise to provide alternatives for better protection of public health and the environment and thus are reviewed in this paper. The emphasis was placed on their basic principles, main applications, and new developments. Advantages and disadvantages of these technologies are compared.

ZHOU, H. ; SMITH, D.W. (2002): Advanced Technologies in Water and Wastewater Treatment. In: Journal of Environmental Engineering and Science : Volume 1 , 247-264. URL [Accessed: 26.11.2011]Status of Water Treatment Plants in India

Three emerging treatment technologies, including membrane filtration, advanced oxidation processes (AOPs), and UV irradiation, hold great promise to provide alternatives for better protection of public health and the environment and thus are reviewed in this paper. The emphasis was placed on their basic principles, main applications, and new developments. Advantages and disadvantages of these technologies are compared.

CPCB (2010): Status of Water Treatment Plants in India. CENTRAL POLLUTION CONTROL BOARD (CPCB) URL [Accessed: 22.05.2019]Advanced Ozone Water Treatment Technology

This article introduces advanced ozonisation systems delivered for treating drinking water and sewage, and a combined process employing ozone and hydrogen peroxide that is currently under development.

HIROTSUJI, Y. ; TETSUYA, T. (1996): Advanced Ozone Water Treatment Technology. In: R&D Progress Report Mitsubishi Electric Advance: URL [Accessed: 26.11.2011]Review of Coagulation Technology for Removal of Arsenic: Case of Chile

This paper presents a summary of the process, concepts and operational considerations for the use of coagulation technology for removal of arsenic in Chile.

SANCHA, A. M. (2006): Review of Coagulation Technology for Removal of Arsenic: Case of Chile. In: Journal of Health, Population and Nutrition: Volume 24 , 267-272. URL [Accessed: 14.05.2012]Advanced Waste Water Treatment

This document includes course contents on advanced treatment plants including suspended and dissolved solid removal, phosphate removal, dissolved organic compounds removal with different techniques.

SUBRAMANIAN, M.S. (n.y): Advanced Waste Water Treatment . Module 1.5. In: NPTEL: URL [Accessed: 22.05.2019]New Technologies for Water and Wastewater Treatment: A Survey of Recent Patents

In this paper, the patents on treatment of water and wastewater approved from 1999 to 2007 were reviewed. An assessment of the current and future outlook for development of new technologies, methods of treatment, equipment and instruments that can be used for water and wastewater treatment applications are presented.

TANSEL, B. (2008): New Technologies for Water and Wastewater Treatment: A Survey of Recent Patents. In: Recent Patents on Chemical Engineering : Volume 1 , 17-26. URL [Accessed: 22.05.2019]How is Purified Recycled Water Made?

This factsheet describes the purification of recycled water specially the so-called 7-barriers process (Source control; Wastewater treatment plant; Microfiltration; Reverse osmosis; Advanced oxidation; Natural environment; Water treatment plant).

QWC (n.y): How is Purified Recycled Water Made? . Fact Sheet – Purified Recycled Water. QUEENSLAND WATER COMMISSION (QWC) URL [Accessed: 22.05.2019]Water Treatment Process

This website contains a lot of information on water treatment technologies.

Ground Water and Drinking Water

The website of the US Environmental Protection Agency provides interesting information about many aspects of drinking water.