Executive Summary

To assure safe water at the point of use it is essential for producers of household water treatment solutions (HWTS) and safe water kiosk operators to comply with quality standards. To comply with national standards in place as well as international standards a thorough applied quality management scheme throughout the production process is helpful. The quality control factsheet elaborates on approaches for quality management of HWTS production and provides insights on international quality standards.

The case study on quality control of TARA highlights mechanisms used and recommendations learned from the development and implementation of its quality control system for the production of liquid chlorine.

What is quality control about?

The general definition of quality control is referred to as mechanisms for the assessment of all aspects involved in a specific process in regard to quality measured as per set standards.

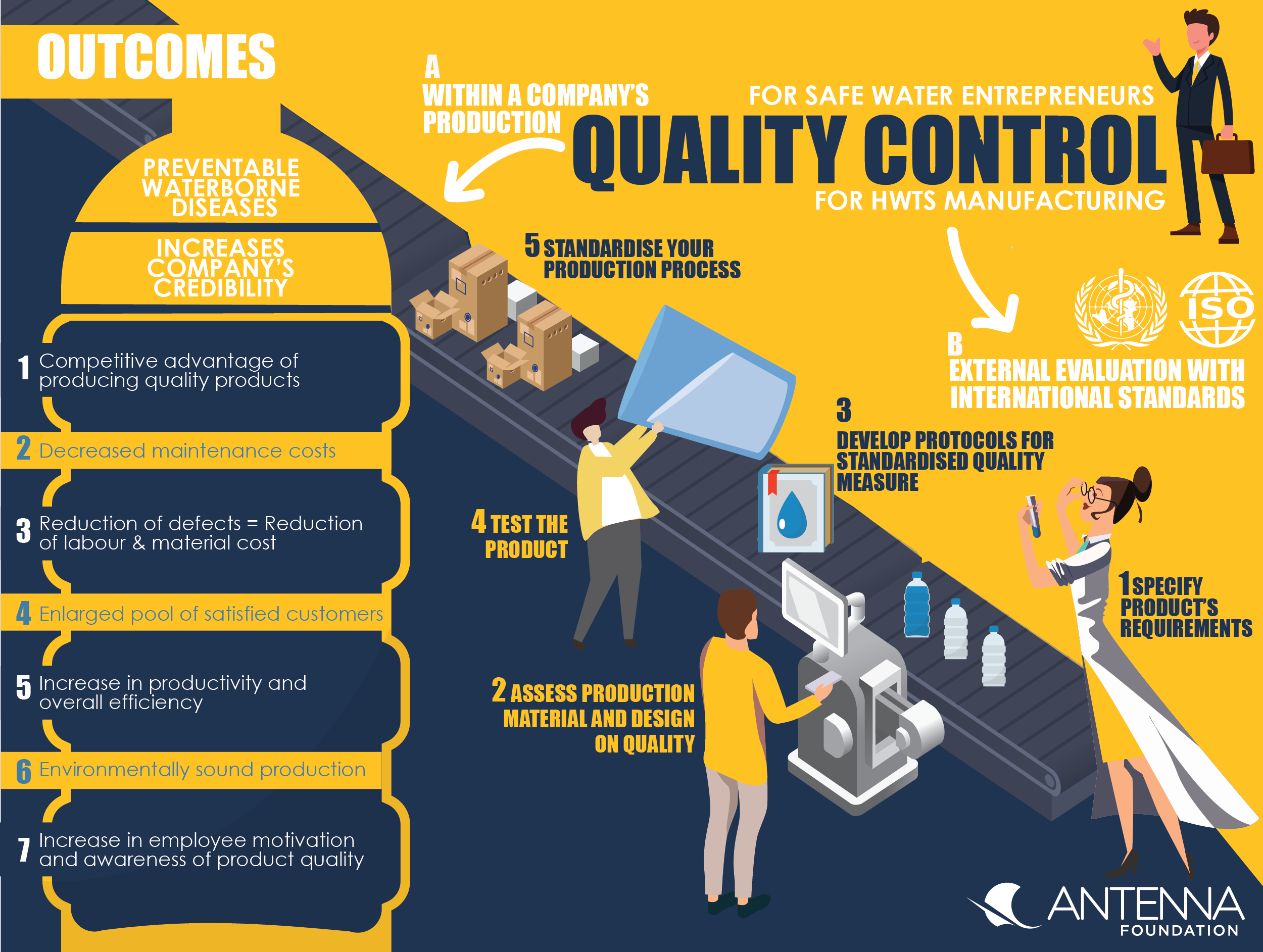

Quality control for manufacturing of HWTS and delivery of safe water entails all aspects of production and delivery to allow safe water for customers at the point-of-use. To assure quality control an enterprise needs a proper quality management strategy and implementation. Thorough quality control can have the following positive outcomes:

- Ability to produce quality products and accordingly leverage market penetration over time due to competitive advantage

- Quality inspection leads to decreased maintenance costs

- Reduction of product defects which reduces variable costs associated with labour and material

- Reduction of waste, scrap and pollution for a more environmentally sound production

- Enlarged pool of satisfied customers

- Increase in employee motivation and awareness of product quality

- Increase in productivity and overall efficiency of production

Why is quality control important for safe water entrepreneurs?

Quality control mechanisms serve two specific purposes that are relevant for safe water enterprises (beside the outcomes explained in the paragraph above):

1. Quality control helps to assure a safe water initiative to produce high quality products. Safe water entrepreneurs selling water or HWTS products have to guarantee that they sell quality products to assure safe water for the consumer. Poorly performing HWTS or unsafe water can lead to waterborne diseases, which are preventable and exactly what every safe water initiative wants to achieve.

2. Quality control helps to comply with quality standards:

- Many development countries do not have specific regulations on HWTS (MONTGOMERY, 2012). If there is no national regulations a company is recommended to comply with WHO water quality standards (WHO, 2011). If your company is able to show the compliance with the WHO standards and requirements, safe water at the point of use can be achieved (with proper handling and maintenance of products by customers) and it also increases a company’s credibility and can support a product’s sales argument (MURCOTT, 2006).

- Countries that do regulate products and services in order to protect consumers by setting standards for products and services like HWTS and vended/delivered water. These regulations establish a minimum threshold regarding quality and performance of products and services. National guidelines can however, vary significantly between countries (for more information see factsheet on laws, policies and regulations).

To comply with regulations and standards for quality control procedures within a company will support verifying its compliance (see following paragraphs for implementation).

Subscribe here to the new Sanitation and Water Entrepreneurship Pact (SWEP) newsletter. SWEP is a network of organizations joining hands to help entrepreneurs design and develop lasting water and sanitation businesses.

For whom is quality control useful?

Quality control is pertinent for every safe water entrepreneur to be able to produce quality products that comply with set standards and allow customers to consume safe water. Considering specific quality control procedures can be a prerequisite to be met in order to allow an enterprise to sell its products and services to the market (MURCOTT, 2006).

How can quality control be used?

Measures for quality control can be taken at a company’s level (1). Internationally formulated standards (2) can be obtained to assure sound quality management. This overview (3) introduces quality control measures for the production of chlorine and ceramic water filters.

1. Aspects of quality control within a company’s production:

- Specify the requirements of your product (e.g. microbiological requirements (e.g. E.coli, protozoa), concentration of disinfectant, flow rate, turbidity removal etc.), design requirements (color, position of stickers etc.). Quality requirements can be referred to as fulfilling WHO standards (WHO, 2011).

- Assess production material on quality.

- Develop protocols for standardised quality measurement (example can be found here).

- Perform test productions to identify potential problems and to evaluate your quality control mechanisms. Such tests are recommended to execute in certified laboratories in order to ensure independence and objectivity of the test.

- Standardise your production process (work towards an efficient production - compare production layout) and identify the different production steps. Define requirements of your product that should be monitored throughout the process. (Find an example here).

For water quality testing a variety of field-testing kits are available in most markets. Examples see below:

| TARAlife India | DelAgua |

|

|

|

| Water quality testing kit from TARAlife. Source: Devalt (2015) http://www.taralife.in/ | Water quality testing kit from DelAgua. Source: DelAgua (2016) http://www.delagua.org/delagua-kits |

Such kits will provide you with the most necessary tools to measure microbiological contamination in water. However, in the long run, it is recommended to either set up your own laboratory or to work together with certified laboratories in order to manage an increasing number of tests. Collaborations with reputed laboratories may further increase your credibility of selling a high-quality product. An interesting evaluation of water testing kits can be found here in order to support your solution finding (CITE, 2015).

2. External evaluation of compliance with international standards:

To assure and reflect externally that your company’s quality management system is adequate, internationally valid standards can be implemented for compliance and comparability. Widely applied standards are the ISO 9000 family from the International Organization for Standardization (ISO).

Specifically, the different ISO 9000 sub-standards address various aspects of quality management for safe water entrepreneurs. These standards provide guidelines and specific tools for companies and organizations to help ensure product and service quality accordingly. Complying with ISO-standards helps companies to address customer’s needs in a consistent was and to improve the quality. To implement ISO standards and evaluate its compliance, a company has to collaborate with external certification bodies (the ISO itself does not issue certifications) that are mandated by ISO. The external audit verifies then if the company implementing the specific ISO standard is complying with it. The costs for obtaining an ISO certificate are detailed in the handbooks describing the compliance process, the costs for the external audit and a company’s internal resources to adapt its structures and processes to the standard. These costs vary and depend on the size of the company and the specific procedures included. The certificate is usually valid for 3 years (ISO, 2018).

3. Quality control mechanisms for active chlorine and ceramic filter production:

- Active chlorine production with WATA® devices:

Manuals for chlorine production with WATA® devices and manuals for quality control mechanisms can be found here.

- Ceramic filter production:

Potters for peace has been doing extensive research on set up and implementation of ceramic filter production sites. Their publications include manuals on testing and quality control:

Quality control for ceramic filter production

Recommended procedures include (for more information see also factsheet on production processes)

- Visual inspection of the produced filter on different factors and at different stages of production (before firing, after firing, after flow rate testing, before packaging).

- Flow rate testing: Test the flow rate and compare it with set quality standards.

- Microbiological contamination testing: Water analysis to check if the filter provides safe water (CMWG, 2010).

This overview of quality control mechanisms and tools shall help you identifying the most pertinent instruments for your respective safe water business initiative. The subsequent case study of TARAlife provides you with hands-on insights on how a safe water enterprise developed and implemented its production quality control mechanisms.

Household Water Filter Evaluation Ahmedabad, India

ISO Standards

Global Status of National Household Water Treatment and Safe Storage Policies

Implementation Critical Factors and Challenges to Scale Up

Guidelines for Drinking-water Quality, Fourth Edition

This volume of the Guidelines for Drinking-water Quality explains requirements to ensure drinking-water safety, including minimum procedures and specific guideline values, and how those requirements are intended to be used. The volume also describes the approaches used in deriving the guidelines, including guideline values. It includes fact sheets on significant microbial and chemical hazards.

WHO (EDITOR) (2011): Guidelines for Drinking-water Quality, Fourth Edition. Geneva: World Health Organization (WHO) URL [Accessed: 11.07.2018]Other manufacturing factors to consider

Best Practice Recommendations for Local Manufacturing of Ceramic Pot Filters for Household Water Treatment

Market Penetration of safe Water at the Base of the Pyramid (BoP) in India

International Scheme to Evaluate Household Water Treatment Technologies

WHO established the international scheme to evaluate HWTS. The Scheme aims to consistently and independently evaluate the performance of HWTS against WHO performance recommendations. The report provides the result of these assessments from a range of HWT technologies including solar, chemical, filtration and ultraviolet (UV). It highlights that of the ten HWT products evaluated, eight were found to meet WHO performance recommendations. The report also recommends specific actions at the national level needed to ensure that health gains from HWT are realized, including strengthening regulation and evaluation of HWTS.

WHO (EDITOR) (2016): International Scheme to Evaluate Household Water Treatment Technologies. Geneva: World Health Organisation URL [Accessed: 20.04.2018]