Executive Summary

Hydrogen peroxide (H2O2), a colourless water-like liquid, is one of the most versatile, reliable and environmentally friendly oxidising agents. The relative safety and simplicity of its uses has led to the development of a number of applications in water treatment such as odour removal, disinfection or metal removal. Hydrogen peroxide is also used in advanced oxidation processes (AOP) and can be combined with catalysts or other oxidisers to produce reactive oxygen species (ROS) able to attack a wide range of organic compounds and microorganisms. The production of hydrogen peroxide is usually performed at industrial scale but can also be done directly in drinking water (or pre-treated wastewater) by electrolysis.

| In | Out |

|---|---|

Freshwater, Drinking Water, Non-biodegradable Wastewater, Treated Water |

Drinking Water, Treated Water |

Introduction

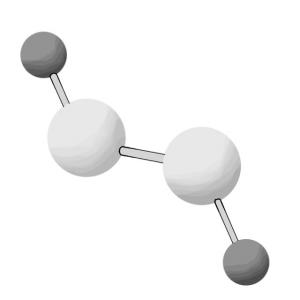

Hydrogen peroxide (H2O2) is a powerful oxidiser that decomposes into an environmental compatible product (water and oxygen). H2O2 is formed under the action of sunlight in natural surface waters due to the presence of natural organic constituents (COOPER & ZIKA 1983). This mechanism contributes to water purification within the environment.

H2O2 is widely used as a bleaching agent for paper and textiles as well as in industrial applications to manufacture or process products. H2O2 can be used for water treatment alone or combined with UV light, a catalyst and/or other oxidants like ozone (see also ozonation). The hydrogen peroxide-based processes are versatile and can treat organics, microbial contamination as well as some inorganic compounds.

H2O2-based treatments can be used both for drinking water purification (e.g. to remove bacteria, odour, micropollutants, etc.), and for municipal or industrial wastewater treatment (effluent disinfection, organics degradation, see also advanced oxidation).

Hydrogen peroxide process

The active part of hydrogen peroxide is the peroxide group, which is an oxidant similar to ozone (see ozonation) or chlorine (see chlorination). When dissolved in water, H2O2 spontaneously breaks down into water and oxygen. This decomposition leads to the formation of reactive oxygen species (ROS), which can oxidise certain organics and metal ions and can also kill pathogens (NEDERHOFF 2000). Optimisation of conditions using H2O2 to destroy these pollutants can involve control of pH, temperature and reaction time. No additional additives are required.

“Catalysed” hydrogen peroxide

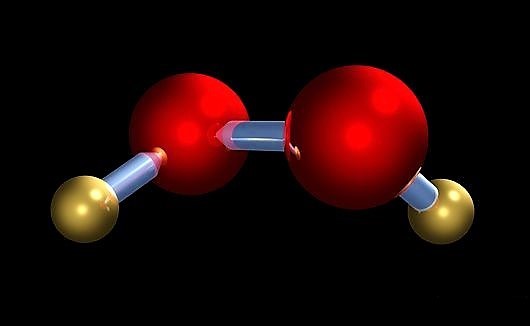

H2O2 can be used in combination with catalysts: UV light and/or other oxidants. The UV light allows the production of an oxidising agent (ROS) called hydroxyl radical (.OH). .OH is one of the strongest oxidants known, much more efficient than hydrogen peroxide alone (AMIN et al. 2008) and is therefore much more efficient in killing microorganisms and degrading organics in water.

H2O2 + UV light --> 2 .OH

Another way of generating hydroxyl radical from H2O2 is the use of a catalyst. The use of iron ions as a catalyst is a common approach and is referred to as Fenton process (STASINAKIS 2008).

Fe2+ + H2O2 --> Fe3+ + OH- + .OH

This reaction is enhanced by the use of solar light (photo-Fenton).

The addition of both hydrogen peroxide and ozone (peroxone) to wastewater accelerates the decomposition of ozone and enhances the production of hydroxyl radical (AL-KDASI 2004).

Hydrogen peroxide generation

The classical manufacturing process involves the catalytic reaction of Hydrogen (H2) with atmospheric oxygen (O2) to give H2O2. Anthraquinone (Q) is used as a hydrogen carrier. Palladium catalyses the reaction between H2 and Q to create H2Q in solution. Then the solution is oxidised by blowing air producing H2O2 (H2Q + O2 --> H2O2 + Q) (DEED 1998). Hydrogen peroxide can also be produced directly in wastewater by water electrolysis using electrodes. The required oxygen can be supplied by transfer from the atmosphere (DROGUI et al. 2001).

Cost considerations

Costs depend on the specifics of the requirement (e.g. H2O2 strength and grade, volume per year, packaging and delivery volumes, and location/proximity to production plant, etc.). For large amounts of technical grade 30% H2O2, the price is roughly a few dollars per kg.

At a glance

| Working principle | H2O2 s breaks down (spontaneously or with a catalyst) into water producing reactive species that react with microorganisms and pollutants |

| Capacity/adequacy | Relatively high-tech equipment required for “catalysed” H2O2 treatments |

| Performance | High efficiency |

| Costs | Relatively high operation costs for “catalysed” H2O2 treatments |

| Self-help compatibility | Engineers are required for the design |

| O&M | Continuous input of H2O2 required |

| Reliability | Reliable if the treatment is designed according to each application |

| Main strength | Very versatile and environmentally compatible oxidising agent |

| Main weakness | Continuous input of H2O2 required |

The strong oxidising power of H2O2 makes it suitable for the destruction of a variety of pollutants such as bacteria, toxic organic compounds and some metals. The process has many applications in drinking water production: taste and odour control, hydrogen sulphide removal, metal removal, ozone enhancement and disinfection. H2O2has also been used for many years to degrade organics in industrial or municipal wastewater. It can also be used for the disinfection of wastewater treatment plants.

When H2O2 is combined with UV light, catalyst or other oxidants, the resulting treatment is more efficient in destroying organics present in high strength wastewaters.

When H2O2 is used on its own, the operational costs are limited to input of H2O2. In case of “catalysed” H2O2 treatments, the design is more complex and additional power and/or chemicals input is required.

Treatment of Textile Wastewater by Advanced Oxidation Processes- a Review

Treatment of Textile Waste Water Using H2O2/UV System

Photochemical Formation of Hydrogen Peroxide in Surface and Ground Waters Exposed to Sunlight

The Manufacture of Hydrogen Peroxide

Hydrogen Peroxide Production by Water Electrolysis: Application to Disinfection

Hydrogen Peroxide for Cleaning Irrigation System

Use of Selected Advanced Oxidation Processes (AOPs) for Wastewater Treatment- A Mini Review

Removal of COD from Oil Recovery Industry Wastewater by the Advanced Oxidation Process (AOP) based on H2O2

This paper describes the treatment of a high pollution strength industrial wastewater with H2O2 combined with UV light and iron ions catalysts.

DINCER, A.R. ; KARAKAYA, N. ; GUNES, E. ; GUNES, Y. (2007): Removal of COD from Oil Recovery Industry Wastewater by the Advanced Oxidation Process (AOP) based on H2O2. In: Global NEST Journal : Volume 10 , 31-38. URL [Accessed: 23.05.2019]Oxidising and Disinfecting by Hydrogen Peroxide Produced in a Two Electrode Cell

This article describes hydrogen peroxide production by a two-electrode cell. The removal of dissolve organic matter and disinfection of municipal wastewater effluents is also discussed.

DROGUI, P. ; ELMALEH, S. ; RUMEAU, M. ; BERNARD, C. ; RAMBAUD, A. (2001): Oxidising and Disinfecting by Hydrogen Peroxide Produced in a Two Electrode Cell. In: Water Research : Volume 35 , 3235-3241. URL [Accessed: 10.10.2011]Elimination of Organic Pollutants using Supported Catalysts with Hydrogen Peroxide

This article is about the treatment of a hardly oxidised aromatic compound (Piric acid) by means of hydrogen peroxide and a supported catalyst (cobalt nitrate immobilised in silica gel).

EL SOUSY, K. ; HUSSEN, A. ; HARTANI, K. ; EL AILA, H. (2007): Elimination of Organic Pollutants using Supported Catalysts with Hydrogen Peroxide. In: Jordan Journal of Chemistry: Volume 2 , 97-103. URL [Accessed: 10.10.2011]Comparison of Energy Requirements of Conventional Ozonation and the AOP O3/H2O2 for Transformation of Target Micropollutants in Diverse Matrices

This document compares the energy requirements for the removal of micropollutants in drinking water treatment plants by ozonation and O3/H2O2. The energy requirements for both treatments are in a similar range however O3/H2O2 reduces the contact time and bromated formation.

KATSOYANNIS, I.A. ; GUNTEN, U. von (n.y): Comparison of Energy Requirements of Conventional Ozonation and the AOP O3/H2O2 for Transformation of Target Micropollutants in Diverse Matrices . In: Techneau Deliverable D2: URL [Accessed: 23.05.2019]Treatment of Textile Dyeing Wastewater by Hydrogen Peroxide and Ferrous Ions

The results of investigations on the applicability of Fenton reagent in the treatment of textile dyeing wastewater are discussed in this article. The optimum conditions and efficiency of the method were determined, taking as an example three types of wastewater produced while dyeing cotton, polyacrylonitrile and polyester.

PERKOWSKI, J. ; KOS, L. (2007): Treatment of Textile Dyeing Wastewater by Hydrogen Peroxide and Ferrous Ions. In: Fibres and Textiles in Eastern Europe : , 78-81. URL [Accessed: 10.10.2011]UV Irradiation Versus Combined UV/Hydrogen Peroxide and UV/Ozone Treatment for the Removal of Persistent Organic Pollutants from Water

This article discusses the efficiency of UV/Hydrogen Peroxide and UV/Ozone treatments for the degradation of persistent organic contaminants including metabolite analysis and economic evaluation.

SONA, M. ; BAUS, C. ; BRAUCH, H.J. (2006): UV Irradiation Versus Combined UV/Hydrogen Peroxide and UV/Ozone Treatment for the Removal of Persistent Organic Pollutants from Water. In: International Conference Ozone and UV: , 69-76. URL [Accessed: 23.05.2019]Removal of Heavy Metal from Industrial Wastewater using Hydrogen Peroxide

The batch removal of heavy metals lead (Pb), zinc (Zn) and copper (Cu) from industrial wastewater effluent using hydrogen peroxide is described in this case study.

BADMUS, M.A.O. ; AUDU, T.O.K. ; ANYATA, B.U. (2007): Removal of Heavy Metal from Industrial Wastewater using Hydrogen Peroxide. In: African Journal of Biotechnology : Volume 6 , 238-242. URL [Accessed: 15.11.2011]Effect of Hydrogen Peroxide on Industrial Wastewater effluents

This article discusses the effect of hydrogen peroxide (added to an advanced treatment plant) on wastewater quality from petrochemical industry.

SONJI ADEYINKA, J. ; RIM-RUKEH, A. (1998): Effect of Hydrogen Peroxide on Industrial Wastewater effluents. In: EnvironmentalMonitoring an Assessment: Volume 59 , 249-256. URL [Accessed: 15.11.2011]A Pilot Study Investigating the Use of Hydrogen Peroxide for the Treatment of Pond Water Delivered by Water Vendors in Dedaye Town Ayeyarwaddy Division Myanmar

This report aims at determining whether pond water treated with a combination of hydrogen peroxide and silver, can effectively provide safe drinking water at the point of consumption.

TRACEY, R. (2011): A Pilot Study Investigating the Use of Hydrogen Peroxide for the Treatment of Pond Water Delivered by Water Vendors in Dedaye Town Ayeyarwaddy Division Myanmar. In: Myanmar Information Management Unit. [Accessed: 10.10.2011]: PDFDisinfection of Wastewater by Hydrogen Peroxide of Peracetic Acid: Development of Procedure for Measurements of Residual Disinfectant an Application to a Physiochemically Treated Municipal Effluent

This document describes the use of hydrogen peroxide as a liquid disinfectant for faecal coliform reduction from wastewater discharge into a river at Montreal urban community wastewater treatment plant.

WAGNER, M. ; BRUMELIS, D. ; GEHR, R. (2002): Disinfection of Wastewater by Hydrogen Peroxide of Peracetic Acid: Development of Procedure for Measurements of Residual Disinfectant an Application to a Physiochemically Treated Municipal Effluent. In: Water Environmental Research: Volume 74 , 33-50. URL [Accessed: 22.05.2019]Peroxone (Ozone/Hydrogen Peroxide)

This chapter of EPA Guidance Manuel provides a lot of scientific information on Peroxone chemistry and applications such as disinfection and organics degradation.

EPA (1999): Peroxone (Ozone/Hydrogen Peroxide). In: EPA Guidance Manual, Alternative Disinfectants and Oxidants: URL [Accessed: 23.05.2019]Instructions for treating your Well with Hydrogen Peroxide to Kill Bacteria and/or to Reduce or Remove Hydrogen Sulfide Odors

This article provides technical and practical information for well treatments by hydrogen peroxide.

MCMAHON, J.P. (n.y): Instructions for treating your Well with Hydrogen Peroxide to Kill Bacteria and/or to Reduce or Remove Hydrogen Sulfide Odors . In: Cleanairpurewater.com:Chemical Summary on Hydrogen Peroxide

This document provides information on chemical properties, environmental fate, and human health effects of hydrogen peroxide.

ORNL (1995): Chemical Summary on Hydrogen Peroxide. Oak Ridge National Laboratory (ORNL). [Accessed: 10.10.2011] PDFUSP Technologies - Technologies for a Clean Environment

This is the website of US Peroxide, a provider of H2O2 and peroxide based, full-service environmental treatment programmes to help purify water, wastewater, soil and air. There is an emphasis on turn-key solutions for municipal wastewater and drinking water treatment; refinery, gas, oil and petrochemical applications; industrial wastewater and air quality treatment; remediation; and UV-Oxidation.

Hydrogen Peroxide

In this website a general description of H2O2 as well as an overview of physic-chemical properties is presented.