Executive Summary

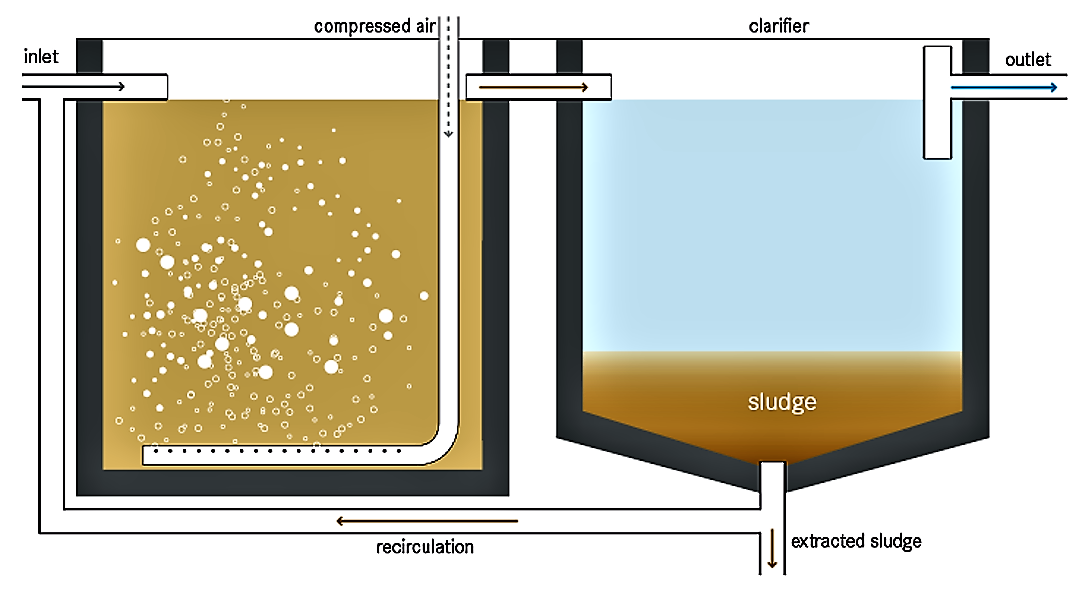

An activated sludge process refers to a multi-chamber reactor unit that makes use of highly concentrated microorganisms to degrade organics and remove nutrients from wastewater to produce a high-quality effluent. To maintain aerobic conditions and to keep the activated sludge suspended, a continuous and well-timed supply of oxygen is required.

| In | Out |

|---|---|

Blackwater, Brownwater, Greywater, Non-biodegradable Wastewater, Energy |

Treated Water, Fertigation Water |

Introduction

Different configurations of the activated sludge process can be employed to ensure that the wastewater is mixed and aerated in an aeration tank. Aeration and mixing can be provided by pumping air or oxygen into the tank or by using surface aerators. The microorganisms oxidize the organic carbon in the wastewater to produce new cells, carbon dioxide and water. Although aerobic bacteria are the most common organisms, facultative bacteria along with higher organisms can be present. The exact composition depends on the reactor design, environment, and wastewater characteristics.

The flocs (agglomerations of sludge particles), which form in the aerated tank, can be removed in the secondary clarifier by gravity settling. Some of this sludge is recycled from the clarifier back to the reactor. The effluent can be discharged into a river or treated in a tertiary treatment facility if necessary for further use.

Design Considerations

Activated sludge processes are one part of a complex treatment system. They are usually used following primary treatment (that removes settleable solids) and are sometimes followed by a final polishing step (see tertiary filtration and disinfection). The biological processes that occur are effective at removing soluble, colloidal and particulate materials. The reactor can be designed for biological nitrification and denitrification, as well as for biological phosphorus removal.

The design must be based on an accurate estimation of the wastewater composition and volume. Treatment efficiency can be severely compromised if the plant is under- or over-dimensioned. Depending on the temperature, the solids retention time (SRT) in the reactor ranges from 3 to 5 days for BOD removal, to 3 to 18 days for nitrification.

The excess sludge requires treatment to reduce its water and organic content and to obtain a stabilized product suitable for end-use or final disposal. It is important to consider this step in the planning phase of the treatment plant). To achieve specific effluent goals for BOD, nitrogen and phosphorus, different adaptations and modifications have been made to the basic activated sludge design. Well known modifications include sequencing batch reactors (SBR), oxidation ditches, extended aeration, moving beds and membrane bioreactors.

Health Aspects/Acceptance

Because of space requirements and odours, Centralized Treatment facilities are generally located in the periphery of densely populated areas. Although the effluent produced is of high quality, it still poses a health risk and should not be directly handled. In the excess sludge pathogens are substantially reduced, but not eliminated.

Operation & Maintenance

Highly trained staff is required for maintenance and trouble-shooting. The mechanical equipment (mixers, aerators and pumps) must be constantly maintained. As well, the influent and effluent must be constantly monitored and the control parameters adjusted, if necessary, to avoid abnormalities that could kill the active biomass and the development of detrimental organisms which could impair the process (e.g., filamentous bacteria).

An activated sludge process is only appropriate for a Centralised Treatment facility with a well-trained staff, constant electricity and a highly developed management system that ensures that the facility is correctly operated and maintained.

Because of economies of scale and less fluctuating influent characteristics, this technology is more effective for the treatment of large volumes of flows.

An activated sludge process is appropriate in almost every climate. However, treatment capacity is reduced in colder environments.

Small and Decentralized Wastewater Management Systems

Decentralised wastewater management presents a comprehensive approach to the design of both conventional and innovative systems for the treatment and disposal of wastewater or the reuse of treaded effluent. Smaller treatment plants, which are the concern of most new engineers, are the primary focus of this book.

CRITES, R. TCHOBANOGLOUS, G. (1998): Small and Decentralized Wastewater Management Systems. New York: The McGraw-Hill Companies IncAppropriate Technology for Municipal Sewerage/Excreta Management in Developing Countries, Thailand Case Study

Assessment of the appropriateness of activated sludge for Thailand.

LUDWIG, H. F. ; MOHIT, K. (2000): Appropriate Technology for Municipal Sewerage/Excreta Management in Developing Countries, Thailand Case Study. In: The Environmentalist: Volume 20 , 215-219. URL [Accessed: 19.08.2014]Biological Wastewater Treatment in Warm Climate Regions Volume 2

Biological Wastewater Treatment in Warm Climate Regions gives a state-of-the-art presentation of the science and technology of biological wastewater treatment, particularly domestic sewage. The book covers the main treatment processes used worldwide with wastewater treatment in warm climate regions given a particular emphasis where simple, affordable and sustainable solutions are required. The 55 chapters are divided into 7 parts over two volumes: Volume One (also available in the SSWM library): Introduction to wastewater characteristics, treatment and disposal; Basic principles of wastewater treatment; Stabilisation ponds; Anaerobic reactors; Volume Two: Activated sludge; Aerobic biofilm reactors; Sludge treatment and disposal.

SPERLING, M. von LEMOS CHERNICHARO, C.A. de (2005): Biological Wastewater Treatment in Warm Climate Regions Volume 2. London: International Water Association (IWA) Publishing URL [Accessed: 26.05.2019]