Executive Summary

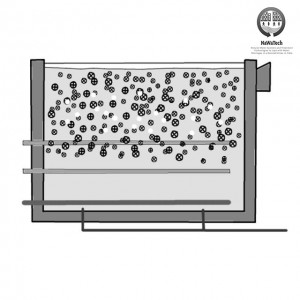

It’s a combination of activated sludge process (suspended growth) and biofilter processes (attached growth). Moving Bed Biofilm Bioreactor (MBBR) process uses the whole tank volume for biomass growth. It uses simple floating media, which are carriers for attached growth of biofilms. Biofilm carrier movement is caused by the agitation of air bubbles. This compact treatment system is effective in removal of BOD as well as nitrogen and phosphorus while facilitating effective solids separation.

| The contents of this factsheet are results of the Indo-European Project NaWaTech- “Natural Water Systems and Treatment Technologies to cope with Water Shortages in Urbanised Areas in India”, co-financed by the EC and the DST – India. |

Design and Construction Principles

This reactor can have any shape and different loads in a reactor volume depending on carrier filling. Design of the reactor is based on the actual wastewater characteristics and local conditions. MBBR units are placed in series based on the load entering each reactor. Neutralised and settled wastewater passes through MBBR for reduction in BOD/COD. Most of the MBBR plants are provided with vertically or horizontally mounted rectangular mesh sieves or cylindrical bar sieves. Biofilm carriers are made up of high density (0.95 g/cm3) polyethelene. These are normally shaped as small cylinders with a cross inside and fins outside. The standard filling of carrier is below 70% with a maximum specific area not more than 465 m2/m3. Generally, design load for COD-BOD removal is 20 g COD / m2d. Smaller carriers need smaller reactor volume at a given loading rate (as g/m2d) when the carrier filling is same. HRT of the reactor is about 3 – 4 hours for effective BOD and nitrogen removal. It is advisable to use MBBR in combination with a septic tank or a pre-coagulation step as a pre-treatment unit, depending on the local conditions and input characteristics. It is a very robust and compact alternative for secondary treatment of municipal wastewater, having removal efficiency for BOD 90 – 95% (low rate) and that of 75 – 80% for high rate. Average nitrogen removal is about 85%. There is no need for sludge recirculation. Phosphorus and faecal coliform reduction is feasible with additional passive (non-mechanical) or active (mechanical) system components.

Operation and Maintenance

A constantly operating MBBR does not require backwashing or return sludge flows. It has minimal head-loss. Coarse-bubble aeration in the aeration zone in the wastewater treatment tank provides ease of operation at low-cost. Agitation continuously moves the carrier elements over the surface of the screen thus preventing clogging. Maintenance of MBBR system includes screening, influent equalisation, clarifier system, sludge handling and integrated control system. There is no need to maintain f/M ratio as there is self-maintenance of an optimum level of productive biofilm. Skilled labour is required for routine monitoring and operations of pumps and blowers.

Cost Considerations

Construction cost of the MBBR is moderate (80%) as compared to other hi-tech wastewater treatment systems, including the screen box, MBBR, clarifier, foundations for units, sludge collection and drying with simple barbed wire fencing for treatment area. The electro-mechanical cost involves machines and monitoring equipment, like pumps for wastewater transfer, blower for air, distribution pipelines for water and air with internal support systems and on-line pressure gauges. Operational costs are inclusive of screen cleaning, biosolids removal, pumping, aeration, and skilled man-power.

Experiences in Europe and other Cities of the World

There are more than 10 variants of MBBR in the various parts of the world such as Kaldnes, Pegasus, Captor, Linpor, etc. These variants are the result different materials used for developing biofilm carriers. MBBR treatment system is being used worldwide to treat different flows high-strength industrial and domestic wastes. Since 1970-80s after inception of Linpor and Kaldnes processes, many existing activated sludge processes were retrofitted with MBBR systems by adding biofilm carriers (ODEGAARD et al. 1994; CPHEEO 2012). It is experienced that sewage treatment units using MBBR processes have treatment efficiency >95% in case of BOD removal and >99% for removal of ammoniacal nitrogen. Most of the European plants (ODEGAARD 2006) are using MBBR for P-removal in addition to COD-BOD reduction. Some Norwegian MBBR systems have potential of nitrification rates as high as 1.2 g NH4-N/m2 d to complete nitrification at low temperatures (11°C), while denitrification rates are found as high as 3.5 g NO3-Nequiv./m2d. This implies that MBBR process improves the performance of biodegration of pollutants even at lower temperatures. In Asian countries like Japan, BOD removal is about 93% and total nitrogen removal is about 75% by upgrading ASP to MBBR. Depending on the extent of pre-treatment, the total HRT of the MBBR for N-removal can be provided in the range of 3 to 5 h.

Experiences in India

MMBR process under various commercial names is being used for sewage treatment in India for the flows ranging from 10 m3/d to 8 MLD, especially for newly developing townships in the urban, semi-urban or rural-urban areas. It is mandatory for them to treat sewage as per statutory standards before releasing into the environment. There are about 300 – 400 installations in India. These systems are found useful in reducing the space footprint of conventional ASP based STPs. Adaptation of MBBR is reported to reduce solids load in secondary sedimentation tank.

There are some limitations of MBBR installations in India. Performance is affected by higher concentration of oil and grease and total suspended solids. The design criteria of MBBR adapted to the Indian conditions are not established, however the technology was introduced in the country a decade ago. Complex process parameters such as biofilm area, biodegration activity and treatment efficiency are based on empirical data of pilot studies or partial full-scale results. The adoption of MBBRs for existing STPs has not been smooth, giving rise to problems, such as clogging because of non-availability of primary sedimentation or large pores of screens. Dissolved oxygen is very essential for the effectiveness of biofilms. One of the major shortcomings of the technology in Indian conditions is that there is less nutrient removal than that of claimed (IIT 2010 & MoUD 2012).

| The research leading to these results has received funding from the European Union Seventh Framework Programme ([FP7/2007-2013]) under Grant Agreement N° [308336] and the Department of Science and Technology of the Government of India DS.O DST/IMRCD/NaWaTech/ 2012/(G). |

Manual on Sewerage and Sewage Treatment. Part A: Engineering

This manual is part A of the updated manuals on sewerage and sewage treatment, prepared by the Central Public Health and Environmental Engineering Organisation (CPHEEO), a department under the Ministry of Urban Development, India. These manuals aim at meeting the professional needs of practising engineers dealing with the sanitation sector in the country that focuses on achieving the goal of 'sanitation for all' within a reasonable timeframe. Part A of the manual is on Engineering aspects related to sewerage system.

CPHEEO (2012): Manual on Sewerage and Sewage Treatment. Part A: Engineering. New Delhi: The Central Public Health and Environmental Engineering Organisation (CPHEEO), Ministry of Urban Development, Government of India URL [Accessed: 04.02.2013]Sewage Treatment in Class I Towns: Recommendations and Guidelines

This report is one of the many reports prepared by IITs to describe the strategy, information, methodology, analysis and suggestions and recommendations in developing Ganga River Basin: Environment Management Plan (GRB EMP). The overall Frame Work for documentation of GRB EMP and Indexing of Reports is presented on the inside cover page.

IIT (2010): Sewage Treatment in Class I Towns: Recommendations and Guidelines. GRB EMP: Ganga River Basin Environment Management Plan. Indian Institute of Technology (IIT) URL [Accessed: 24.03.2015]Recent Trends in Technologies in Sewerage System

As per Census 2001, 30.66 million urban households which form 35.49% of the urban households suffer inadequate access to sanitation. According to the report of the Central Pollution Control Board (2009), the estimated sewage generation from Class-I Cities and Class-II Towns is 38254.82 million litres per day (MLD) out of which only 17787.38 MLD (35%) is being treated and the remaining is disposed into the water bodies without any treatment due to which three-fourths of surface water resources are polluted. The Ministry of Urban Development conducted a rating of class I cities on sanitation related parameters in 2009-10.Out of 423 cities, only four were in the blue category scoring more than 66 points out of 100. No city achieved the distinction of being a green city i.e. a city scoring more than 90 out of 100.

MoUD (2012): Recent Trends in Technologies in Sewerage System. New Delhi: Ministry of Urban Development, Government of India URL [Accessed: 24.03.2015]A New Moving Bed Biofilm Reactor - Applications and Results

A new moving bed biofilm reactor has been developed in Norway. The biomass is attached to carrier elements that move freely along with the water in the reactor. It is demonstrated in the paper that this results in a very compact reactor and a very efficient biomass. Experiences from pilot and full-scale testing of the reactor in municipal and industrial wastewater treatment applications are presented and discussed.

ODEGAARD, H. ; RUSTEN, B. ; WESTRUM, T. (1994): A New Moving Bed Biofilm Reactor - Applications and Results. In: Water Science and Technology: Volume 29 , 157-165. URL [Accessed: 24.03.2015]Innovations in Wastewater Treatment: The Moving Bed Biofilm Process

This paper describes the moving bed biofilm reactor (MBBR) and presents applications of wastewater treatment processes in which this reactor is used. The MBBR processes have been extensively used for BOD/COD-removal, as well as for nitrification and denitrification in municipal and industrial wastewater treatment. This paper focuses on the municipal applications. The most frequent process combinations are presented and discussed. Basic design data obtained through research, as well as data from practical operation of various plants, are presented.

ODEGAARD, H. (2006): Innovations in Wastewater Treatment: The Moving Bed Biofilm Process. In: Water Science and Technology: Volume 53 , 17-33. URL [Accessed: 24.03.2015]Compendium of Natural Water Systems and Treatment Technologies to cope with Water Shortages in Urbanised Areas in India

The Compendium of NaWaTech Technologies presents appropriate water and wastewater technologies that could enable the sustainable water management in Indian cities. It is intended as a reference for water professionals in charge of planning, designing and implementing sustainable water systems in the Indian urban scenario, based on a decentralised approach.

BARRETO DILLON, L. ; DOYLE, L. ; LANGERGRABER, G. ; SATISH, S. ; POPHALI, G. (2013): Compendium of Natural Water Systems and Treatment Technologies to cope with Water Shortages in Urbanised Areas in India. Berlin: EPUBLI GMBH URL [Accessed: 11.12.2015]http://www.nawatech.net/

This is the official webpage of the NaWaTech Collaborative Project, containing all key information related to the different case studies, activities and results of the project.

.png)