Executive Summary

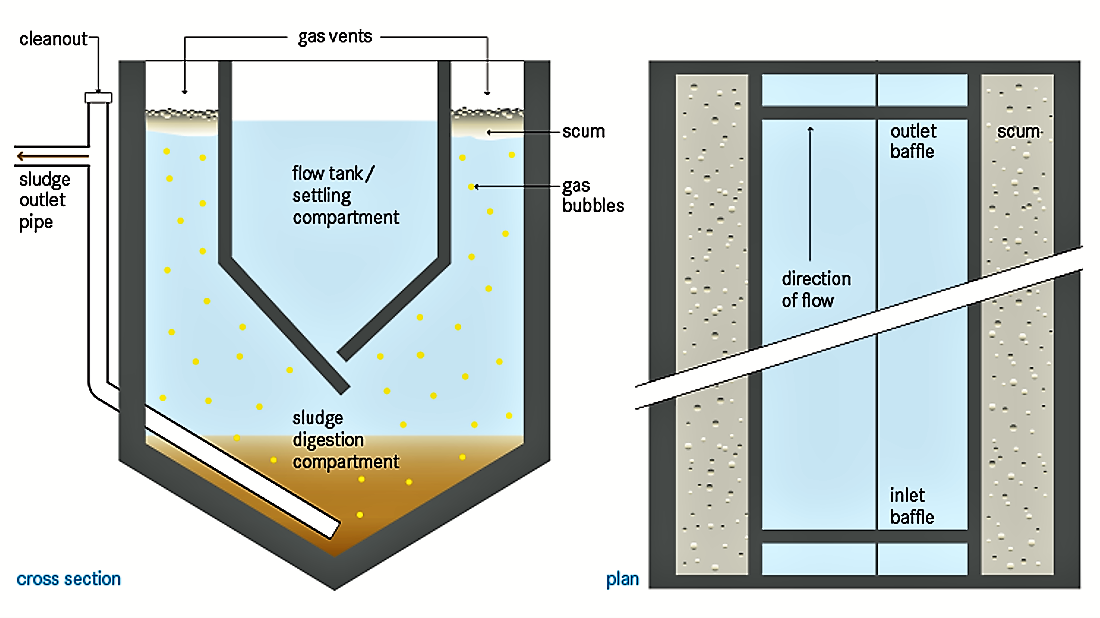

The Imhoff tank is a primary treatment technology for raw wastewater, designed for solid-liquid separation and digestion of the settled sludge. It consists of a V-shaped settling compartment above a tapering sludge digestion chamber with gas vents.

| In | Out |

|---|---|

| Blackwater, Brownwater, Excreta, (Organic Solid Waste) |

Blackwater (settled), Faecal Sludge, (Biogas) |

Introduction

The Imhoff tank is a robust and effective settler that causes a suspended solids reduction of 50 to 70%, COD reduction of 25 to 50%, and leads to potentially good sludge stabilisation – depending on the design and conditions. The settling compartment has a circular or rectangular shape with V-shaped walls and a slot at the bottom, allowing solids to settle into the digestion compartment, while preventing foul gas from rising up and disturbing the settling process. Gas produced in the digestion chamber rises into the gas vents at the edge of the reactor. It transports sludge particles to the water surface, creating a scum layer. The sludge accumulates in the sludge digestion chamber, and is compacted and partially stabilised through anaerobic digestion.

Design Considerations

The Imhoff tank is usually built underground with reinforced concrete. It can, however, also be built above ground, which makes sludge removal easier due to gravity, although still requiring pumping up of the influent. Small prefabricated Imhoff tanks are also available on the market. Hydraulic retention time is usually not more than 2 to 4 h to preserve an aerobic effluent for further treatment or discharge (find other treatment technologies here and also under http://ecompendium.sswm.info/sanitation-technologies).

T-shaped pipes or baffles are used at the inlet and the outlet to reduce velocity and prevent scum from leaving the system. The total water depth in the tank from the bottom to the water surface may reach 7 to 9.5 m. The bottom of the settling compartment is typically sloped 1.25 to 1.75 vertical to 1 horizontal and the slot opening can be 150 to 300 mm wide. The walls of the sludge digestion compartment should have an inclination of 45° or more. This allows the sludge to slide down to the centre where it can be removed.

Dimensioning of the anaerobic digestion compartment depends mainly on sludge production per population equivalent, on the targeted degree of sludge stabilisation (linked to the desludging frequency) and the temperature. The digestion chamber is usually designed for 4 to 12 months sludge storage capacity to allow for sufficient anaerobic digestion. In colder climates longer sludge retention time and, therefore, a greater volume is needed.

For desludging, a pipe and pump have to be installed or access provided for vacuum trucks and mobile pumps (see also motorised emptying and transport). A bar screen or grit chamber (see pre-treatment technologies) is recommended before the Imhoff tank to prevent coarse material from disturbing the system.

Health Aspects/Acceptance

As the effluent is almost odourless, it is a good option for primary treatment if subsequent treatment takes place, e.g., in open ponds, constructed wetlands (see also vertical flow constructed wetland, horizontal flow constructed wetland or free-water surface constructed wetland) or trickling filters. Greenhouse gases produced in low quantities may, however, generate odours locally. Pathogen removal is low and all outputs should be treated. Adequate protective clothing is necessary for workers who may get in contact with the effluent, scum or sludge. A vacuum truck should be used to empty the sludge, if there is no pumped outlet installed. Users should not attempt to empty the pit themselves except with a manual technology like the gulper (see also motorised emptying and human-powered emptying). Users should be careful when opening the tank because noxious and flammable gases may be released.

Costs Considerations

Construction costs are slightly higher than the costs for a septic tank (SANIMAS 2005). Also the costs for desludging (motorised or manual) must be considered. Moreover, it is a pre-treatment facility and in many cases connected to further treatment installations (e.g. leach field, soak pits, horizontal flow, vertical flow or free-surface constructed wetlands).

Operation & Maintenance

Operation and maintenance are possible at low cost, if trained personnel are in charge. Flow paths have to be kept open and cleaned out weekly, while scum in the settling compartment and the gas vents has to be removed daily if necessary. Stabilised sludge from the bottom of the digestion compartment should be removed according to the design. A minimum clearance of 50 cm between the sludge blanket and the slot of the settling chamber has to be ensured at all times.

Imhoff tanks are recommended for domestic or mixed wastewater flows between 50 and 20,000 population equivalents. They are able to treat high organic loads and are resistant against organic shock loads. Space requirements are low.

Imhoff tanks can be used in warm and cold climates. As the tank is very high, it can be built underground if the groundwater table is low and the location is not flood prone.

Filières d'Epuration Adaptées aux Petites Collectivités

The aim of this document is to help to identify the best technology options for small communities depending on the situation at hand.

ALEXANDRE, O. BOUTIN, C. DUCHENE, PH. LAGRANGE, C. LAKEL, A. LIENARD, A. ORDITZ, D. (1998): Filières d'Epuration Adaptées aux Petites Collectivités . (= Document technique FNDAE , 22 ). Lyon: Centre National du Machinisme Agricole, du Genie Rural, des Eaux et des Forets (CEMAGREF) URL [Accessed: 08.10.2013]Rehabilitation of the Imhoff Tank Treatment Plant in Las Vegas, Santa Barbara Honduras, Central America

This case study provides general information about Imhoff tanks and insights into implementation and operational problems. Recommendations for operation and maintenance are provided.

HERRERA, A. (2006): Rehabilitation of the Imhoff Tank Treatment Plant in Las Vegas, Santa Barbara Honduras, Central America. Master thesis. Austin: Department of Civil, Architectural and Environmental Engineering, University of TexasHonduras Wastewater Treatment: Chemically Enhanced Primary Treatment and Sustainable Secondary Treatment Technologies for Use with Imhoff Tanks

This work seeks to expand upon the body of knowledge pertinent to enhance the treatment efficacy of Imhoff tanks within Honduras. It also includes a definition for what an Imhoff tank is and explanation of how the system works.

McLEAN, R.C. (2008): Honduras Wastewater Treatment: Chemically Enhanced Primary Treatment and Sustainable Secondary Treatment Technologies for Use with Imhoff Tanks. Pomona: California State Polytechnic University URL [Accessed: 01.06.2019]Philippines Sanitation Source Book and Decision Aid

This Sanitation Sourcebook distils some of the core concepts of sanitation in a user-friendly format so that the book can serve as a practical reference to sanitation professionals and investment decision-makers, particularly the local governments. The annexe contains a practical collection of factsheets on selected sanitation system options.

WSP (2007): Philippines Sanitation Source Book and Decision Aid. pdf presentation. Washington: Water and Sanitation Program (WSP). URL [Accessed: 01.06.2019]