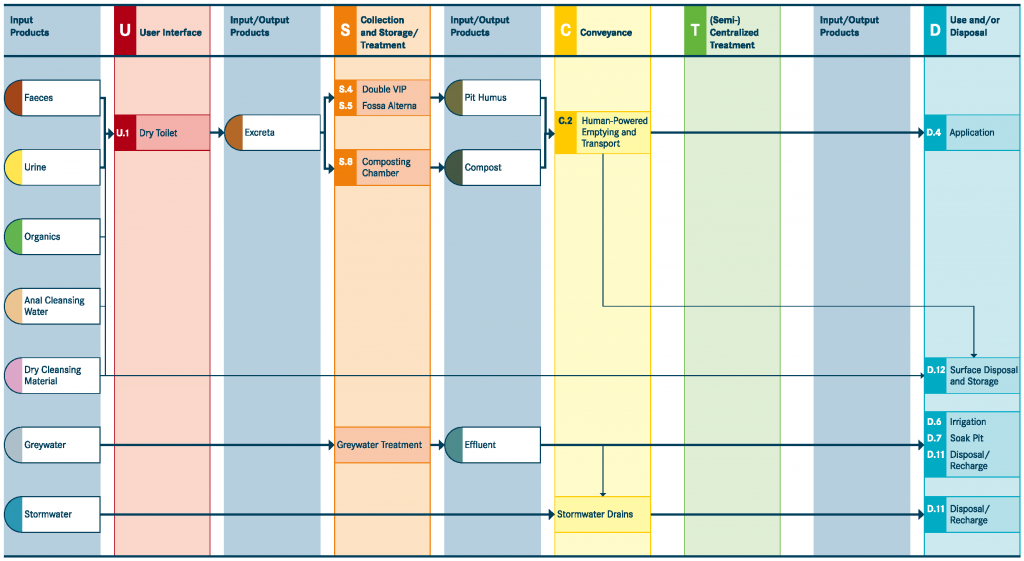

System 2: Waterless Pit System without Sludge Production. Source: TILLEY et al (2014)

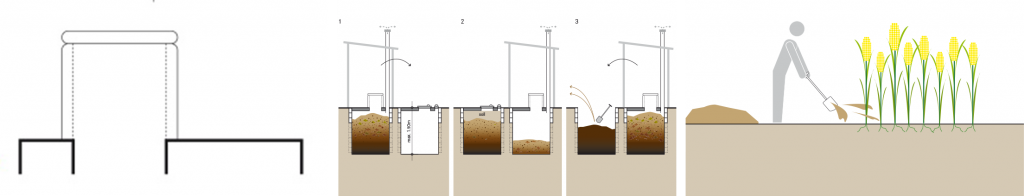

Schematics of system 2 components. Source: TILLEY et al (2014)

This system is designed to produce a solid, earth-like material by using alternating pits or a Composting Chamber. Inputs to the system can include Urine, Faeces, Organics, Anal Cleansing Water, and Dry Cleansing Materials. There is no use of Flushwater.

A Dry Toilet is the recommended User Interface for this system, although a UDDT or Waterless Urinals and Flush Urinals could also be used if the Urine is highly valued for application. A Dry Toilet does not require water to function and in fact, water should not be put into this system; Anal Cleansing Water should be kept at a minimum or even excluded if possible.

The User Interface is directly connected to a Double Ventilated Improved Pit (VIP), Fossa Alterna or a Composting Chamber for Collection and Storage/Treatment.

Two alternating pits, as in the Double Ventilated Improved Pit (VIP) or Fossa Alterna, give the material an opportunity to drain, degrade, and transform into Pit Humus (sometimes also called EcoHumus), a nutrient-rich, hygienically improved, humic material which is safe to excavate. When the first pit is full, it is covered and temporarily taken out of service. While the other pit is filling with Excreta (and potentially Organics), the content of the first pit is allowed to rest and degrade. Only when both pits are full is the first pit emptied and put back into service. This cycle can be indefinitely repeated. As the Excreta in the resting pit is draining and degrading for at least one year, the resulting Pit Humus needs to be manually removed using shovels, and vacuum truck access to the pits is not necessary.

A Composting Chamber is not strictly a pit technology, but it can also have alternating chambers and, if properly operated, produces safe, useable Compost. For these reasons it is included in this system template.

The Pit Humus or Compost that is generated from the Collection and Storage/Treatment technology can be removed and transported for Use and/or Disposal manually using a Human-powered Emptying and Transport service. Since it has undergone significant degradation, the humic material is quite safe to handle and use as soil conditioner in agriculture (Use of Compost). If there are concerns about the quality of the Pit Humus or Compost, it can be further composted in a dedicated composting facility before it is used. If there is no use for the product, it can be temporarily stored or permanently disposed of (Surface Disposal (Solids)).

This system is different from system 1 (System 1: Single Pit System) regarding the product generated at Collection and Storage/Treatment level. In the previous system, the Sludge required further treatment before it could be used, whereas the Pit Humus and Compost produced in this system are ready for Use and/or Disposal following Collection and Storage/Treatment.

Considerations

Because the system is permanent and can be indefinitely used (as opposed to some Single Pits, which may be filled and covered), it can be used where space is limited. Additionally, because the product must be manually removed, this system is suitable for dense areas that cannot be served by trucks for mechanical emptying (Motorised Emptying and Transport). This system is especially appropriate for water-scarce areas and where there is an opportunity to use the humic product as soil conditioner. The material that is removed should be in a safe, useable form, although proper personal protection should be used during removal, transport and use.

The success of this system depends on proper operation and an extended storage period. If a suitable and continuous source of soil, ash or Organics (leaves, grass clippings, coconut or rice husks, woodchips, etc.) is available, the decomposition process is enhanced and the storage period can be reduced. The required storage time can be minimized if the material in the pit remains well aerated and not too moist. Therefore, the Greywater must be collected and treated separately. Too much moisture in the pit will fill the air voids and deprive the microorganisms of oxygen, which may impair the degradation process. Dry Cleansing Materials can usually be collected in the pit or chamber together with the Excreta, especially if they are carbonaceous (e.g., toilet paper, newsprint, corncobs, etc.) as this may help degradation and air flow.

Guidelines for the safe use of Excreta have been published by the World Health Organization (WHO) and are referenced on the relevant technology information sheets.

Compendium of Sanitation Systems and Technologies. 2nd Revised Edition

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E., ULRICH L., LÜTHI, C., REYMOND P. and ZURBRÜGG C. (2014): Compendium of Sanitation Systems and Technologies. 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 03.05.2023] PDFCompendium of Sanitation Systems and Technologies (Arabic)

This is the Arabic version of the Compendium of Sanitation Systems and Technologies. The Compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E. ULRICH, L. LUETHI, C. REYMOND, P. SCHERTENLEIB, R. ZURBRUEGG, C. (2014): Compendium of Sanitation Systems and Technologies (Arabic). 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) PDF