Executive Summary

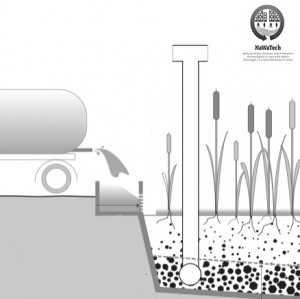

Sludge drying bed (SDB) is the most widely used method for sludge dewatering. Sludge drying involves natural ways of drying to mechanical ways of removing water content. SDB is generally used for small and medium sized communities (TCHOBANOGLOUS et al. 2003). The selection of the technology will depend upon land availability, climatic factors, the quantity and composition of the sludge. The construction of this is usually undertaken with civil structure.

Design and Construction Principle

Design of a Sludge Drying Bed

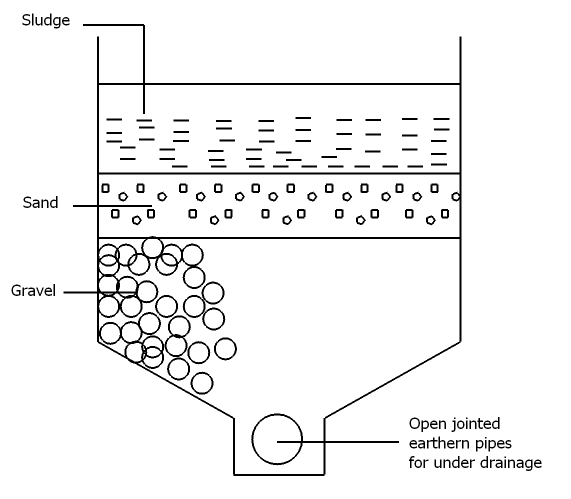

The prediction of the drying rate is an empirical part of the designing the system. Drying of the sludge can be divided in to two different stages, namely drainage and evaporation (CHAI 2007). The design of SDB is based mainly on site specifications, as well as environmental and climatic factors. The sizing of the sludge drying beds should be done considering the worst case scenario (CERONIO et al. 1999). The loading is based on per capita basis or on a unit loading of pounds of dry solids per square foot per year (TCHOBANOGLOUS et al. 2003). There are mainly five types of sludge drying methods viz. conventional sand beds, paved drying beds, artificial media beds, vacuum assisted and solar. The typical conventional SDB has dimensions of 6 m width, 6 - 30 m length, with sand layer ranging from 230 – 300 mm depth. The sand should have a uniformity coefficient of not over 4.0 and effective size of 0.3 to 0.75 mm. The piping to the sludge drying beds should be designed for velocity of at-least 0.75 m/s (TCHOBANOGLOUS et al. 2003). The sludge is placed on the bed in 20–30 cm layers and allowed to dry. Sludge cake removal is manual by shovelling into wheel-barrows, trucks, scraper, or front-end loader. The drying period is 10–15 days, and the moisture content of the cake is 60 – 70%. Sludge loading rate is 100–300 kg dry solids/ m2 /year for uncovered beds (AL-MALACK et al. 2002).

Operation and Maintenance

The application of sludge treatment methods differs from country to country due to differences in operating conditions and energy prices (GHAZY et al. 2011). Conventional sludge drying is very simple, but trained staff for operation and maintenance is required to ensure proper functioning. This method doesn’t require electrical energy (TILLEY et al. 2008). The O & M also includes application of sludge, desludging, control of drainage system and the control of the secondary treatments for percolate or dried sludge.

Cost Considerations

This conventional sludge treatment technology is more land intensive rather than energy intensive. Based on the quantity of wastewater to be treated the sizing of the sludge drying bed changes. The capital investment for this treatment unit is the highest in terms of the land requirement followed by the construction costs. The O & M requirements include the labour hours, fuel energy, back washing as well as the annual materials and maintenance parts.

Experiences in Europe and other Cities of the World

SDBs are being used throughout the world especially in United States since the beginning of the 20th century, but over the years its applicability is limited due to the environmental and climatic factors (CARPENTER 1938). In the United States, the majority of Waste Water Treatment Plants (WWTPs) with capacities less than 5 MGD (equal to 18.93 m3/day) use SDBs. Similarly, Russia and other Eastern European countries use SDBs in more than 80% of the WWTPs (TUROVSKIY & MATHAI 2006). By 2009, Egypt had approx. 303 WWTPs handling 11.85 x106 m3 /day of sewage. Most of these WWTPs use natural sludge drying beds (GHAZY et al. 2009).

In Africa, a STP at Cambérène (Dakar, Senegal) uses SDB for sludge treatment since 2006. The initial design underestimated the sludge volumes to be treated and overestimated the sludge concentrations by 40%. This caused serious problems in operations. After detailed study this issue was resolved and the capacities of the SDBs were increased from 200 kg TS/m2/year to 400 kg TS/m2/year. Currently, the plant is running at 300 kg TS/m2/year, thus allowing for an additional bed-scrubbing period of about ten days (EAWAG 2009).

Experiences in India

Many of the cities in India including Chennai, Thane, Pune, Patna, Chandigardh, and Bhopal use the conventional sludge drying beds as a part of sludge treatment process. The quantum of sludge to be treated is generally very high due to the amount of wastewater that is generated in these cities. The climatic conditions in India are also favourable for the use of SDBs as the solar energy is available in ample in Indian subcontinent. In the city of Patna, many municipal wastewater treatment plants are using the SDBs as part of sludge treatment technology. Plants at Beur, Saidpur have installed SDB having total capacity of 405 m3 each. Furthermore, cities including Raipur, Khurd (Chandigarh), Ahemdabad, Vasna, Rajkot, Vadodara, Surat (located in the state of Gujarat) also have multiple sewage treatment plants, which include sludge drying beds as the treatment units (CPCB 2005). Further to that The Central Public Health & Environmental Engineering Organisation under Ministry of Urban Development has published the design guidelines for Sludge Drying Beds in India (CPHEEO 2012).

Characterization, Utilization and Disposal of Municipal Sludge: The State of the Art

This paper presents a literature review concerning sludge generation, production, and treatment. Alternatives of sludge utilization and disposal are also presented. In addition, the paper provides information on the regulations on municipal sludge reuse and disposal, set by related agencies, mainly the United States Environmental Protection Agency (U.S.EPA). The regulations were formulated to protect the environment, the health of workers handling municipal sludge, and the health of the public.

AL-MALACK, M.H. ; ABUZAID, N.S. ; BUKHARI, A.A. ; ESSA, M.H. (2002): Characterization, Utilization and Disposal of Municipal Sludge: The State of the Art. In: The Arabian Journal for Science and Engineering: Volume 27 URL [Accessed: 14.04.2015]Sludge Drying on Open and Covered Drying Beds

The purpose of this paper is to present data collected from various Long Island plants where sludge is dried on glass-covered beds, and to describe experiments on specially constructed beds for filtration of sludge.

CARPENTER, L.V. (1938): Sludge Drying on Open and Covered Drying Beds. In: Sewage Works Journal: Volume 10 , 503. URL [Accessed: 14.04.2015]Guidelines for the Design and Operation of Sewage Sludge Drying Beds

This paper consists of a literature study about the characterisation of sludge and its behaviour during the dewatering process and a questionnaire survey of 30 plants using sludge beds.

CERONIO, A.D. VAN VUUREN, L.R.J. WARNER, A.P.C. (1999): Guidelines for the Design and Operation of Sewage Sludge Drying Beds. WRC Report. Pretoria: Water Research Commission (WRC) URL [Accessed: 14.04.2015]Statistical Dynamic Features of Sludge Drying Systems

This paper proposed a statistical dynamic framework to analyze the physical mechanisms of sludge drying process. Based on the new method, the fractal dimension of a drying structure was derived analytically and its relationship with some controlling factors was analyzed. Experiments were performed to validate the theoretical analyses and good agreement was found. Not only provides a reasonable mechanistic description of internal structures of drying sludge, this work is of help to many industrial applications.

CHAI, L.H. (2007): Statistical Dynamic Features of Sludge Drying Systems. In: International Journal of Thermal Sciences: Volume 46 , 802-811. URL [Accessed: 14.04.2015]Status of Sewage Treatment in India

This reports analyzes and presents in detail the gap between sewage generation and treatment capacity, the technologies used for sew age treatment in India, performance of 115 sewage plants studied by Central Pollution Control Board with plant-specific technical remarks and also discusses the efficacies of various treatment technologies.

CPCB (2005): Status of Sewage Treatment in India. New Delhi: Central Pollution Control Board (CPCB), Ministry of Urban Development of India URL [Accessed: 14.04.2015]Manual on Sewerage and Sewage Treatment. Part A: Engineering

This manual is part A of the updated manuals on sewerage and sewage treatment, prepared by the Central Public Health and Environmental Engineering Organisation (CPHEEO), a department under the Ministry of Urban Development, India. These manuals aim at meeting the professional needs of practising engineers dealing with the sanitation sector in the country that focuses on achieving the goal of 'sanitation for all' within a reasonable timeframe. Part A of the manual is on Engineering aspects related to sewerage system.

CPHEEO (2012): Manual on Sewerage and Sewage Treatment. Part A: Engineering. New Delhi: The Central Public Health and Environmental Engineering Organisation (CPHEEO), Ministry of Urban Development, Government of India URL [Accessed: 04.02.2013]Sandec News No. 10

10th Sandec News 2009, containing information on different topics.

EAWAG (2009): Sandec News No. 10. Duebendorf: EAWAG - Department of Water and Sanitation in Developing Countries URL [Accessed: 10.04.2013]Sewage Sludge Management in Egypt: Current Status and Perspectives towards a Sustainable Agricultural Use

This paper discusses the current situation of sewage sludge management in Egypt presenting a brief overview of the existing wastewater treatment plants, sludge production and characteristics as well as options of beneficial use and potential demand of sewage sludge under Egyptian conditions. The characteristics of sewage sludge are discussed considering the results of own sampling and analysis as well as previous studies. Furthermore, alternative treatment scenarios for sewage sludge, which have been recently developed in Egypt, are discussed and perspectives for a sustainable agricultural use are outlined.

GHAZY, M. ; DOCHORN, T. ; DICHTL, N. (2009): Sewage Sludge Management in Egypt: Current Status and Perspectives towards a Sustainable Agricultural Use. In: International Journal of Environmental, Ecological, Geological and Geophysical Engineering: Volume 3 , 387-395. URL [Accessed: 14.04.2015]Economic and Environmental Assessment of Sewage Sludge Treatment Processes Application in Egypt

The main objectives of this study are to evaluate and compare the application of aerobic/anaerobic digestion, natural/mechanical dewatering and composting processes in sewage sludge treatment options in Egypt with respect to various parameters including energy balance, environmental impacts, sludge capacities and economic aspects. Moreover, the area of application of each treatment process, according to the Egyptian conditions, is evaluated.

GHAZY, M. DOCKHORN, T. DICHTL, N. (2011): Economic and Environmental Assessment of Sewage Sludge Treatment Processes Application in Egypt. (= Fifteenth International Water Technology Conference, IWTC-15 2011, Alexandria, Egypt ). Alexandria: International Water Technology Association (IWTA) URL [Accessed: 14.04.2015]Informed Choice Catalogue

This informed choice catalogue for community based wastewater treatment technologies helps to identify suitable sanitation options and facilitates the assessment of different sanitation system components with regard to stakeholder preferences. A powerful tool for technical bottom-up planning giving overall information about technical options at a "glance".

SANIMAS (2005): Informed Choice Catalogue. pdf presentation. BORDA and USAID URL [Accessed: 29.05.2019]Wastewater Engineering, Treatment and Reuse

Compendium of Sanitation Systems and Technologies

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E., LUETHI, C., MOREL, A., ZURBRUEGG, C. and SCHERTENLEIB, R. (2008): Compendium of Sanitation Systems and Technologies. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) and Water Supply and Sanitation Collaborative Council (WSSCC) URL [Accessed: 15.02.2010] PDFWastewater Sludge Processing

This book discusses unit operations used for processing sludge and the available methods for final disposition of the processed product. Topics discussed include sludge quantities and characteristics, thickening and dewatering, aerobicand anaerobic digestion, alkaline stabilization, composting, thermal drying and incineration, energy consumption, and the beneficial use of biosolids.

TUROVSKIY, I.S. MATHAI, P.K. (2006): Wastewater Sludge Processing. New Jersey: John Wiley & SonsCompendium of Natural Water Systems and Treatment Technologies to cope with Water Shortages in Urbanised Areas in India

The Compendium of NaWaTech Technologies presents appropriate water and wastewater technologies that could enable the sustainable water management in Indian cities. It is intended as a reference for water professionals in charge of planning, designing and implementing sustainable water systems in the Indian urban scenario, based on a decentralised approach.

BARRETO DILLON, L. ; DOYLE, L. ; LANGERGRABER, G. ; SATISH, S. ; POPHALI, G. (2013): Compendium of Natural Water Systems and Treatment Technologies to cope with Water Shortages in Urbanised Areas in India. Berlin: EPUBLI GMBH URL [Accessed: 11.12.2015]http://www.nawatech.net/

This is the official webpage of the NaWaTech Collaborative Project, containing all key information related to the different case studies, activities and results of the project.