Executive Summary

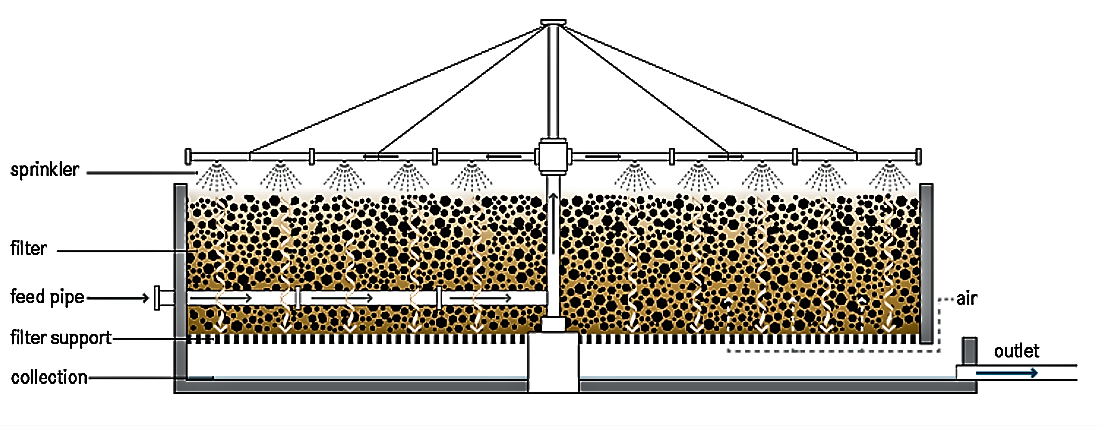

A trickling filter , also called trickling biofilter, biofilter, biological filter and biological trickling filter , is a fixed-bed, biological reactor that operates under (mostly) aerobic conditions. Pre-settled wastewater is continuously ‘trickled’ or sprayed over the filter. As the water migrates through the pores of the filter, organics are aerobically degraded by the biofilm covering the filter material.

| In | Out |

|---|---|

Faceal Sludge, pre-treated Blackwater or Fertigation water |

Introduction

Trickling filters are conventional aerobic biological wastewater treatment units, such as active sludge systems or rotating biological contactors. The advantage of all these systems is that they are compact (i.e. applicable in densely populated urban settings) and that they efficiently reduce organic matter (JENSSEN et al. 2004). However, they are high-tech and generally require skilled staff for construction as well as for operation.

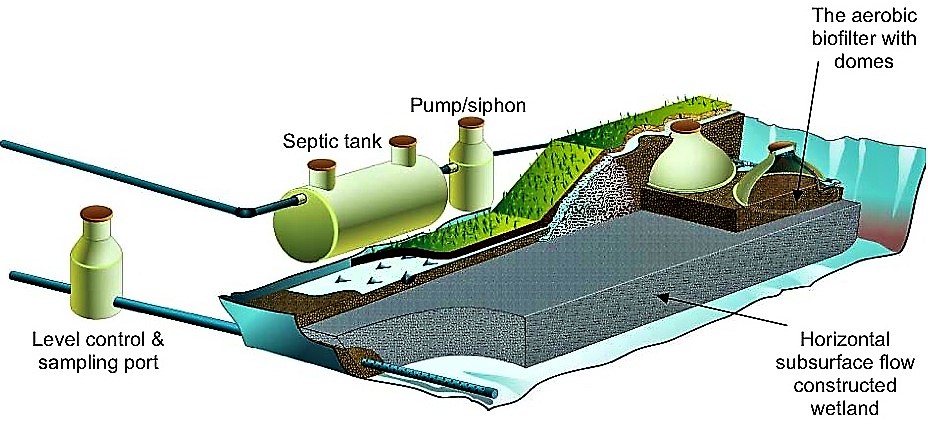

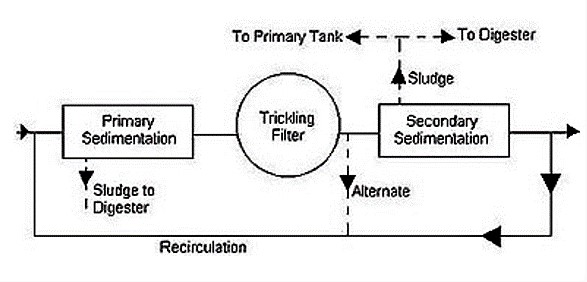

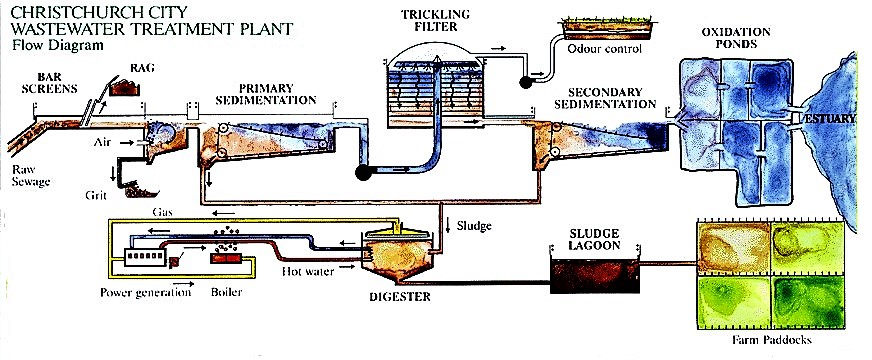

Trickling filters are a secondary treatment after a primary setting process (see also septic tanks or pre treatment).

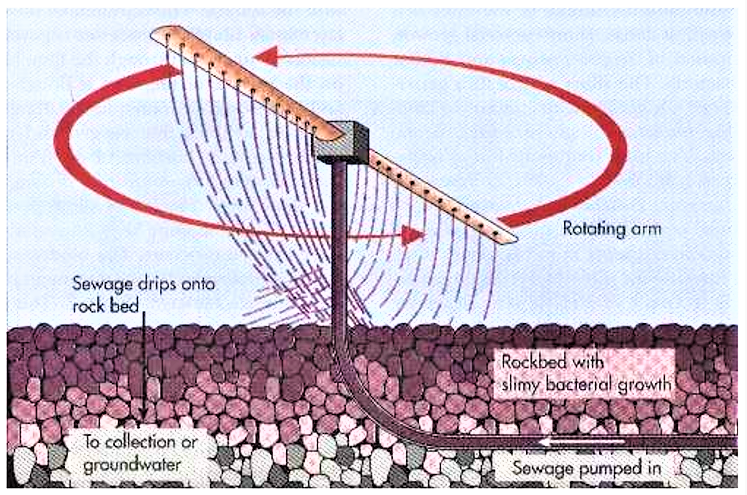

The trickling filter consists of a cylindrical tank and is filled with a high specific surface area material, such as rocks, gravel, shredded PVC bottles, or special pre-formed plastic filter media. A high specific surface provides a large area for biofilm formation. Organisms that grow in the thin biofilm over the surface of the media oxidize the organic load in the wastewater to carbon dioxide and water, while generating new biomass. This happens mainly in the outer part of the slime layer, which is generally of 0.1 to 0.2 mm thickness (U.S.EPA 2000).

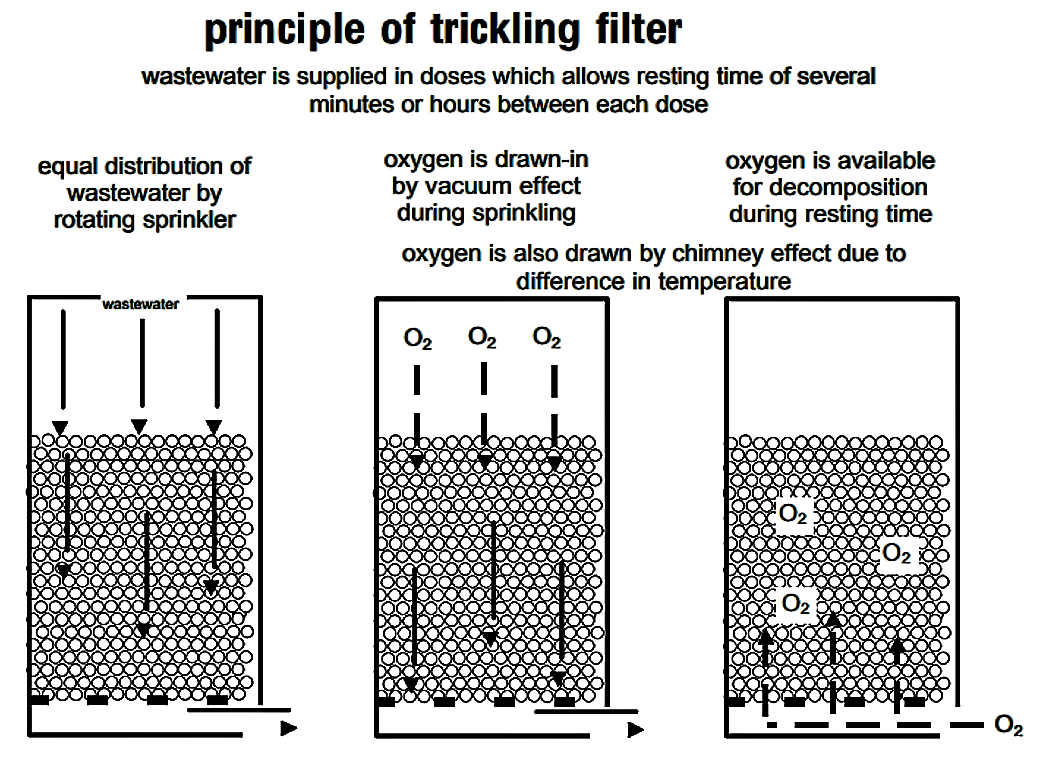

The incoming pre-treated wastewater is ‘trickled’ over the filter, e.g., with the use of a rotating sprinkler. In this way, the filter media goes through cycles of being dosed and exposed to air. However, oxygen is depleted within the biomass and the inner layers may be anoxic or anaerobic.

The word filter is somehow misleading, as physical straining of solids is only marginal. The removal of organic substances occurs by use of bacterial action (UNEP & MURDOCH UNIVERSITY 2004). Therefore trickling filters are also called bio-, or biological filters to emphasise that the filtration. Fixed film biological treatment are also used in other common treatment processes such rotating biological contactors of fixed film activated sludge systems.

Design Considerations

The filter is usually 1 to 2.5 m deep, but filters packed with lighter plastic filling can be up to 12 m deep.

Oxygen is obtained by direct diffusion from air into the filter and the biological film (UNEP 2004) from the bottom through a spontaneous airflow due to temperature difference. Therefore, both ends of the filter should be ventilated (TILLEY et al. 2008), and sub-soil construction is not common (HEEB et al. 2008). However, in cold climates, and where energy for aeration and pumping is easily available, sub-soil construction can give protection against temperatures shocks.

The primary factors that must be considered in the design of trickling filters include (MOUNTAIN EMPIRE COMMUNITY COLLEGE n.y.):

- the type of filter media to be used

- the spraying system, and

- the configuration of the under-drain system

Filter media

The ideal filter material is low-cost and durable, has a high surface to volume ratio, is light, and allows air to circulate. Whenever it is available, crushed rock or gravel is the cheapest option. Specially manufactured plastic media, such as corrugated plastic sheets or hollow plastic cylinders, that optimise surface area for bacteria to attach free movement of air are also available (UNEP & MURDOCH UNIVERSITY 2004). The particles should be uniform and 95% of them should have a diameter between 7 and 10 cm. A material with a specific surface area between 45 and 60 m2/m3 for rocks and 90 to 150 m2/m3 for plastic packing is normally used. Larger pores (as in plastic packing) are less prone to clogging and provide for good air circulation. Primary treatment is also essential to prevent clogging and to ensure efficient treatment.

Spraying System

Adequate air flow is important to ensure sufficient treatment performance and prevent odours. To evenly distribute the water on the filter, a “rotary sprinkler/distributor” is most often used. The rotary distributor consists of a hollow vertical centre column carrying two or more radial pipes or arms some cm above the filter media (to spread out uniformly and prevent interfering with ice accumulation during winter season in colder climates), each of which contains a number of nozzles or orifices for discharging the wastewater onto the bed (MOUNTAIN EMPIRE COMMUNITY COLLEGE n.y.).

Underdrain System

The underdrains should provide a passageway for air at the maximum filling rate. A perforated slab supports the bottom of the filter, allowing the effluent and excess sludge to be collected. The trickling filter is usually designed with a recirculation pattern for the effluent to improve wetting and flushing of the filter material.

With time, the biomass will grow thick and the attached layer will be deprived of oxygen; it will enter an endogenous state, will lose its ability to stay attached and will slough off (U.S. EPA 2000) . High-rate loading conditions will also cause sloughing.

With time, growth and reproduction of the bacteria results in an increase of thickness of the biofilm layer, particularly at the top of the trickling filter. If the biofilm grows to thick, oxygen is prevented to enter and anaerobic organisms develop (U.S.EPA 2000; UNEP & MURDOCH UNIVERSITY 2004). The continuous growth, the metabolic waste products of the anaerobic bacteria, and the maintenance of a hydraulic load to the filter eventually lead to the fact that the microorganisms near the surface lose their ability to stick to the filter. When microorganisms fall off the medium and are carried with the effluent, this process is known as sloughing (U.S. EPA 2000). The under-drain system allows transporting these solid to a clarifier, where the solids settle and separate from the treated effluent (UNEP 2004).

To keep sloughing minimal, the organic and the hydraulic load to the filters should guarantee a balance between the growth of the biofilm and the amount of rinsed-out dead bio-film (HEEB et al. 2008). The collected effluent should be clarified in a settling tank to remove any biomass that may have dislodged from the filter. It can then be discharged to surface waters (see also surface water disposal and surface groundwater recharge), percolated to groundwater (see also sub surface and surface groundwater recharge) or used in irrigation (ECOSANRES 2008). The hydraulic and nutrient loading rate (i.e., how much wastewater can be applied to the filter) is determined based on the characteristics of the wastewater, the type of filter media, the ambient temperature, and the discharge requirements.

Trickling filters can be combined in decentralised wastewater treatment systems (e.g. following septic tanks or anaerobic baffled reactors) but are also often part of large centralised wastewater treatment plants (e.g. following activated sludge treatment).

Although trickling filters are more easily operated and consume less energy than activated sludge processes, they have a lower removal efficiency for solids and organic matter, they are more sensitive to low air temperatures, and can become infested with flies and mosquitoes (UNEP et al. 2004).

Treatment Capacity

Trickling filters are designed primarily for BOD removal. Treatment performances depend on wastewater characteristics, hydraulic and organic loading, medium type, maintenance of optimal dissolved oxygen levels, and recirculation rates (UNEP 2004). A BOD reduction of 60 to 85 % can be expected with loading rates of 1 kg BOD/m3/day (SASSE & BORDA 1998; U.S.EPA 2000; UNEP 2004; WSP 2008;). Bacterial reductions have been reported to be 1 to 2 logs of faecal Coliforms (UNEP 2004), respectively 60 to 90 % of total Coliforms (WSP 2008). Physical adsorption of virus on the biofilm or elimination by predation are additional factors in pathogen elimination in trickling filters (STRAUSS n.y.). Total suspended solids (TSS) removal is expected to be very low (due to the down-flow regime) and pre-settling as well as removal of the solids from the effluent is recommended.

Because aerobic bacteria convert ammonia to nitrate (WSP 2008), some nitrification can also be achieved, depending on the organic loading rate to the filter, the temperature and the aeration. Total nitrogen removal varies from 0 to 35 % (UNEP 2004; WSP 2008), while phosphorus removal of 10 to 15 % might be expected (UNEP 2004). However, the capacity for nutrient removal of trickling filters depends strongly on the operation conditions, and while some sources indicate a high removal of ammonia (U.S. EPA 2000) other indicate no capacity of trickling filters for nutrients (UNEP et al. 2004).

Health Aspects/Acceptance

Odour and fly problems require that the filter be built away from homes and businesses. Appropriate measures must be taken for pre- and primary treatment (settling), secondary treatment (eventually final clarifier) , effluent discharge and solids treatment, all of which can still pose health risks.

Costs Considerations

Capital costs are moderate to high depending on type of filter materials and feeder pumps used. Operation and maintenance costs are moderate or high depending on electricity consumption of feeder pumps (UNEP 2004). In any case expert design and skilled labour is required for construction and maintenance (e.g. prevent clogging, ensure adequate flushing, monitor hydraulic and organic loads, control filter flies, etc.). Another cost factor is energy consumption of pumps (e.g. to bring the water to the top of the filter) and for the sprinkler system. However, this requirements are low compared to actively aerated systems such as activated sludge processes.

Operation and Maintenance

A skilled operator is required to monitor the filter and repair the pump in case of problems. The sludge that accumulates on the filter must be periodically washed away once in five to seven years or more (WSP 2008) to prevent clogging and keep the biofilm thin and aerobic. High hydraulic loading rates (flushing doses) (> 0.8 m3/m3h, SASSE & BORDA 1998) and temporal collection of the effluent can be used to flush the filter. Optimum dosing rates and flushing frequency should be determined from the field operation.

The rotary distributor may also require regular cleaning or technical maintenance.

The packing must be kept moist. Constant hydraulic loading can be maintained through suction level controlled pumps or dosing siphons (HEEB et al. 2008). This may be problematic at night when the water flow is reduced or when there are power failures. Recirculation of effluent may also be required to avoid low flow conditions (WSP 2008), but a too strong flow overload would flush out the microbes.

Besides drying out, excessive odour can also arise when anaerobic conditions arise due to excessive organic loadings or insufficient aeration.

Snails grazing on the biofilm and filter flies are well known problems associated with trickling filters and must be handled by backwashing and periodic flooding.

At a Glance

| Working Principle | Wastewater trickles vertically through a porous media (e.g. a stone bed) with high specific surface. The biofilm growing on the media removes organic matter under aerobic conditions. |

| Capacity/Adequacy | Semi-centralised to centralised. The system is usually applied in urban areas for treatment of domestic wastewater. It can be applied for bigger and smaller communities. |

| Performance | BOD: 65 to 90 %. Low TSS removal. Total Coliforms: 1 to 2 log units |

| Costs | Medium; investment costs depend on type of filter materials and feeder pumps used; operational costs determined by electricity consumption of feeder pumps. |

| Self-help Compatibility | Low. Design, planning and implementation by expert consultants; no community labour contribution possible; feeder pumps required; permanent staff required for operation. |

| O&M | Civil engineer needed for construction, professional service providers required |

| Reliability | Resistant to shock loadings but the systems does not work during power failures. |

| Main strength | High treatment efficiency with lower area requirement compared to wetlands or ponds; resistant to shock loading. |

| Main weakness | Requires expert skills, pumps and continuous electrical power, as well as ample and continuous wastewater flow required |

This technology can only be used following primary clarification since high solids loading will cause the filter to clog. Since trickling filter only receive liquid waste, they are not suitable where water is scarce or unreliable. Moreover, trickling filters require some specific material (i.e. pumps and replacement parts) and skilled design and maintenance (SASSE & BORDA 1998). A low-energy (gravity) trickling system can be designed, but in general, a continuous supply of power and wastewater is required. However, energy requirement for operating a trickling filter is less than for an activated sludge process (UNEP & MURDOCH UNIVERSITY 2004) or aerated lagoons.

Compared to other technologies (e.g., Waste Stabilization Ponds), trickling filters are compact, although they are still best suited for peri-urban or large, rural settlements.

Trickling filters can treat domestic blackwater or brownwater, greywater or any other biodegradable effluent. They are typically applied as post-treatment for upflow anaerobic sludge blanket reactors or for further treatment after activated sludge treatment. In any case, primary sedimentation (see also septic tanks or pre treatment) is compulsory to avoid clogging of the filter bed and a secondary clarification step and post-treatment of excess sludge (e.g. in sedimentation ponds, unplanted drying beds, planted drying beds or anaerobic digesters) is also compulsory (WSP 2008).

Trickling filters can be built in almost all environments, but special adaptations for cold climates are required. Proper insulation, reduced effluent recirculation, and improved distribution techniques can lessen the impact of cold temperatures (UNEP 2004).

Introduction to Greywater Management. FactSheet

This factsheet provides information and experiences on simple greywater treatments including sorption, infiltration, vertical soil filters and also trickling filters.

ECOSANRES (2008): Introduction to Greywater Management. FactSheet. (= EcoSanRes Factsheet , 8 ). Stockholm: Stockholm Environment Institute EcoSanRes Programme URL [Accessed: 22.04.2010]Ecosan Curriculum 2.3

Sustainable Wastewater Management in Urban Areas

A document about sustainable wastewater management in urban areas.

JENSSEN, P.D. GREATOREX, J.M. WARNER, W. S. (2004): Sustainable Wastewater Management in Urban Areas. (= Kapitel 4. Kurs WH33, Konzeptionen dezentralisierter Abwasserreinigung und Stoffstrommanagement ). Hannover: University of HannoverTrickling Filters - Filter Classification

Decentralised Wastewater Treatment Methods for Developing Countries

Different operation and maintenance options are presented with respect to sustainable plant operation, the use of local resources, knowledge, and manpower.

NATURGERECHTE TECHNOLOGIEN, BAU- UND WIRTSCHAFTSBERATUNG (TBW) GmbH (2001): Decentralised Wastewater Treatment Methods for Developing Countries. GTZ and GATEIntroduction to Greywater Management

The report gives a comprehensive description of the main components in successful greywater management. Examples as well as recommendations are given for designing and dimensioning treatment systems.

RIDDERSTOLPE, P. (2004): Introduction to Greywater Management. (= EcoSanRes Publication Series, Report 2004-4 ). Stockholm: Stockholm Environment Institute, EcoSanRes Programme URL [Accessed: 19.05.2010]DEWATS

Exhaustive report on technological, operational and economic aspects of decentralised waste water treatment systems. Spreadsheet examples support the reader in designing and planning waste water treatment systems components.

SASSE, L. BORDA (1998): DEWATS. Decentralised Wastewater Treatment in Developing Countries. Bremen: Bremen Overseas Research and Development Association (BORDA) URL [Accessed: 03.06.2019]Health (Pathogen) Considerations Regarding the Use of Human Waste in Aquaculture

This study reviews the potential health risks and current epidemiological evidence for actual risks from pathogen transmission through wastewater aquaculture.

STRAUSS, M. (n.y): Health (Pathogen) Considerations Regarding the Use of Human Waste in Aquaculture. (pdf presentation). Switzerland: Department of Water and Sanitation in Developing Countries at the Swiss Federal Institute of Aquatic Science and TechnologyWastewater Engineering, Treatment and Reuse

Compendium of Sanitation Systems and Technologies. 2nd Revised Edition

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E., ULRICH L., LÜTHI, C., REYMOND P. and ZURBRÜGG C. (2014): Compendium of Sanitation Systems and Technologies. 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 03.05.2023] PDFCompendium of Sanitation Systems and Technologies

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E., LUETHI, C., MOREL, A., ZURBRUEGG, C. and SCHERTENLEIB, R. (2008): Compendium of Sanitation Systems and Technologies. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (EAWAG) and Water Supply and Sanitation Collaborative Council (WSSCC) URL [Accessed: 15.02.2010] PDFTrickling Filter - The History of Fixed Film Wastewater Treatment Systems

Trickling Filters

Short Factsheet on the applicability and design criteria of trickling filters including a lot of information on operation and maintenance (form the United States Environment Protection Agency (EPA).

U.S. EPA (2000): Trickling Filters. (= Wastewater Technology Fact Sheet, EPA 832-F , 14 ). United States Environment Protection Agency URL [Accessed: 03.06.2019]Trickling Filters Nitrification

Short factsheet on nitrification in trickling filters (form the United States Environment Protection Agency (EPA).

U.S.EPA (2000): Trickling Filters Nitrification. (= Wastewater Technology Fact Sheet, EPA 832-F , 15 ). United States Environment Protection Agency URL [Accessed: 17.05.2012]Chapter 4. Wastewater Technologies

Comprehensive overview (in form of factsheets) on the different components of wastewater treatment systems (collection, transfer, onsite treatment, centralised and decentralised treatment, reuse, sludge management and disposal) adapted to the Caribbean Region. Industrial wastewater treatment is also discussed.

UNEP (2004): Chapter 4. Wastewater Technologies. In: UNEP (2004): A Directory of Environmentally Sound Technologies for the Integrated Management of Solid, Liquid and Hazardous Waste for SIDS in the Caribbean Region. Nairobi: 63-125.Environmentally sound technologies in wastewater treatment for the implementation of the UNEP/GPA "Guidelines on Municipal Wastewater Management"

Technical information on environmentally sound technologies in wastewater treatment.

UNEP ; MURDOCH UNIVERSITY (2004): Environmentally sound technologies in wastewater treatment for the implementation of the UNEP/GPA "Guidelines on Municipal Wastewater Management". The Hague: United Nations Environment Programme Global Programme of Action (UNEP/GPA), Coordination OfficeGuidelines on Municipal Wastewater Management

Technology Options for Urban Sanitation in India. A Guide to Decision-Making

These guidance notes are designed to provide state governments and urban local bodies with additional information on available technologies on sanitation. The notes also aid in making an informed choice and explain the suitability of approaches.

WSP (2008): Technology Options for Urban Sanitation in India. A Guide to Decision-Making. pdf presentation. New Delhi: Water and Sanitation Program (WSP) URL [Accessed: 03.06.2019]Introduction to Greywater Management

The report gives a comprehensive description of the main components in successful greywater management. Examples as well as recommendations are given for designing and dimensioning treatment systems.

RIDDERSTOLPE, P. (2004): Introduction to Greywater Management. (= EcoSanRes Publication Series, Report 2004-4 ). Stockholm: Stockholm Environment Institute, EcoSanRes Programme URL [Accessed: 19.05.2010]Trickling Filters Nitrification

Short factsheet on nitrification in trickling filters (form the United States Environment Protection Agency (EPA).

U.S.EPA (2000): Trickling Filters Nitrification. (= Wastewater Technology Fact Sheet, EPA 832-F , 15 ). United States Environment Protection Agency URL [Accessed: 17.05.2012]The Attached Growth Process – An old technology takes on new forms

The Pipeline Newsletter was formerly edited by the National Small Flows Clearinghouse (NSFC) and is now edited by the National Environmental Service Center based at the West Virginia University (USA). Popular with small community officials, citizens, maintenance and inspection personnel, and community educators, each quarterly issue of Pipeline focuses on a single wastewater topic and presents it in an easy-to-read format. This issues deals with attached-growth processes, including trickling filters, rotating biological contactors, sand filters, peat filters, textile filters and subsurface flow wetland.

NSFC (2004): The Attached Growth Process – An old technology takes on new forms. (= Pipeline , 1 / 15 ). Morgantown: National Small Flows Clearinghouse URL [Accessed: 22.04.2010]Decentralised Wastewater Treatment Methods for Developing Countries

Different operation and maintenance options are presented with respect to sustainable plant operation, the use of local resources, knowledge, and manpower.

NATURGERECHTE TECHNOLOGIEN, BAU- UND WIRTSCHAFTSBERATUNG (TBW) GmbH (2001): Decentralised Wastewater Treatment Methods for Developing Countries. GTZ and GATEWastewater Engineering, Treatment and Reuse

Compendium of Sanitation Systems and Technologies. 2nd Revised Edition

This compendium gives a systematic overview on different sanitation systems and technologies and describes a wide range of available low-cost sanitation technologies.

TILLEY, E., ULRICH L., LÜTHI, C., REYMOND P. and ZURBRÜGG C. (2014): Compendium of Sanitation Systems and Technologies. 2nd Revised Edition. Duebendorf, Switzerland: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 03.05.2023] PDFChapter 4. Wastewater Technologies

Comprehensive overview (in form of factsheets) on the different components of wastewater treatment systems (collection, transfer, onsite treatment, centralised and decentralised treatment, reuse, sludge management and disposal) adapted to the Caribbean Region. Industrial wastewater treatment is also discussed.

UNEP (2004): Chapter 4. Wastewater Technologies. In: UNEP (2004): A Directory of Environmentally Sound Technologies for the Integrated Management of Solid, Liquid and Hazardous Waste for SIDS in the Caribbean Region. Nairobi: 63-125.Environmentally sound technologies in wastewater treatment for the implementation of the UNEP/GPA "Guidelines on Municipal Wastewater Management"

Technical information on environmentally sound technologies in wastewater treatment.

UNEP ; MURDOCH UNIVERSITY (2004): Environmentally sound technologies in wastewater treatment for the implementation of the UNEP/GPA "Guidelines on Municipal Wastewater Management". The Hague: United Nations Environment Programme Global Programme of Action (UNEP/GPA), Coordination OfficeTechnology Options for Urban Sanitation in India. A Guide to Decision-Making

These guidance notes are designed to provide state governments and urban local bodies with additional information on available technologies on sanitation. The notes also aid in making an informed choice and explain the suitability of approaches.

WSP (2008): Technology Options for Urban Sanitation in India. A Guide to Decision-Making. pdf presentation. New Delhi: Water and Sanitation Program (WSP) URL [Accessed: 03.06.2019]Biological Filters: Trickling and RBC Design

The application of biological filters (fixed film processes) for the removal of ammonia from brackish or salt wastewaters from fish farms is discussed. The biological removal of ammonia in fixed-film processes is explained and design examples for ammonia removal in either trickling filters or rotating biological contactors are discussed.

HOCHHEIMER, J.N. WHETON, F.W. (1998): Biological Filters: Trickling and RBC Design. In: LIBEY, G.S. ; TIMMONS, M.B. (1998): Proceedings of the Second International Conference on Recirculating Aquaculture Roanoke. Virginia: 291–318. URL [Accessed: 18.03.2010]Ecosan Greywater Demonstration Project. Case study from Kuching, Malaysia

The city of Kuching is currently lacking a wastewater treatment plant, and the local subsurface conditions make a conventional centralised wastewater system expensive to implement. Most buildings are equipped with two separate wastewater outlets, one outlet for blackwater and one for greywater. The proposed system treats greywater from nine households, and consists of a baffled septic tank, followed by a dosing chamber from where the greywater flows into four vertical down-flow, single-pass aerobic biofilters before reaching a subsurface horizontal-flow planted filter. Finally, the treated greywater is discharged into a stormwater drain.

MOREL A. DIENER S. (2006): Ecosan Greywater Demonstration Project. Case study from Kuching, Malaysia. In: MOREL, A. ; DIENER, S. ; (2006): Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods. Duebendorf: 76-79.Trickling Filter Design

Short PowerPoint Presentation on the design of trickling filters available on the Tropak Hompage hosted by the Turkish Dokuz Eylul University in Izmir.

LESIKAR, B. (2000): Trickling Filter Design. Izmir: Dokuz Eylul University URL [Accessed: 24.02.2010]Biological Wastewater Treatment in Warm Climate Regions Volume 1

Biological Wastewater Treatment in Warm Climate Regions gives a state-of-the-art presentation of the science and technology of biological wastewater treatment, particularly domestic sewage. The book covers the main treatment processes used worldwide with wastewater treatment in warm climate regions given a particular emphasis where simple, affordable and sustainable solutions are required. The 55 chapters are divided into 7 parts over two volumes: Volume One: (1) Introduction to wastewater characteristics, treatment and disposal; (2) Basic principles of wastewater treatment; (3) Stabilisation ponds; (4) Anaerobic reactors; Volume Two (also available in the SSWM library): (5) Activated sludge; (6) Aerobic biofilm reactors; (7) Sludge treatment and disposal.

SPERLING, M. von LEMOS CHERNICHARO, C.A. de (2005): Biological Wastewater Treatment in Warm Climate Regions Volume 1. London: International Water Association (IWA) Publishing URL [Accessed: 26.05.2019]Trickling Filters

Short Factsheet on the applicability and design criteria of trickling filters including a lot of information on operation and maintenance (form the United States Environment Protection Agency (EPA).

U.S. EPA (2000): Trickling Filters. (= Wastewater Technology Fact Sheet, EPA 832-F , 14 ). United States Environment Protection Agency URL [Accessed: 03.06.2019]Trickling Filters Nitrification

Short factsheet on nitrification in trickling filters (form the United States Environment Protection Agency (EPA).

U.S.EPA (2000): Trickling Filters Nitrification. (= Wastewater Technology Fact Sheet, EPA 832-F , 15 ). United States Environment Protection Agency URL [Accessed: 17.05.2012]Onsite Wastewater Treatment Systems Manual

Rather old design manual for onsite wastewater treatment options. However, valuable information on established systems such as septic tanks, sand filters, aerobic treatment units (suspended growth and fixed film), disinfection, nutrient removal as well as wastewater segregation and recycling are given. Additional information is given on disposal methods and appurtenances.

U.S.EPA (1980): Onsite Wastewater Treatment Systems Manual. (= EPA 625/1-80 , 12 ). United States Environmental Protection Agency, Office of Water Office of Research and Developmenthttp://en.wikipedia.org/

Wikipedia entry on trickling filters.