المُلخص التنفيذي

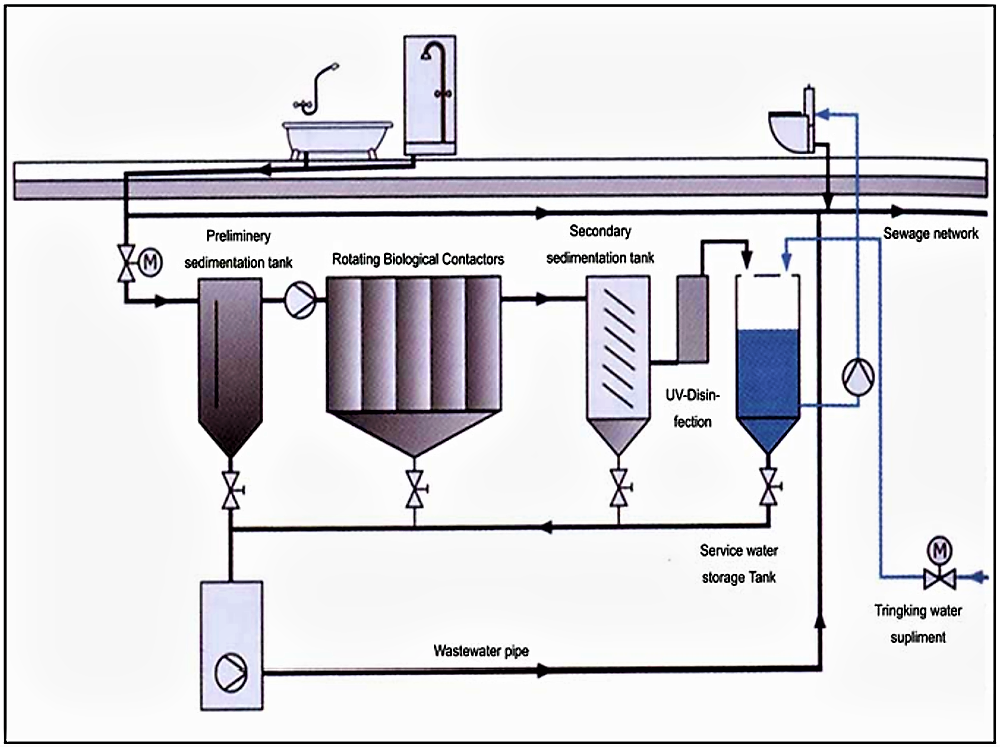

Rotating biological contactors (RBC), also called rotating biological filters, are fixed-bed reactors consisting of stacks of rotating disks mounted on a horizontal shaft. They are partially submerged and rotated as wastewater flows through. They are used in conventional wastewater treatment plants as secondary treatment after primary sedimentation of domestic grey- or blackwater, or any other biodegradable effluent. The microbial community is alternately exposed to the atmosphere and the wastewater, allowing both aeration and assimilation of dissolved organic pollutants and nutrients for their degradation.

| المُدخلات | المُخرَجات |

|---|---|

Faecal Sludge, Fertigation Water |

Rotating biological contactors (RBC) are a conventional aerobic biological wastewater treatment unit. Conventional biological treatment means activated sludge systems and fixed film systems such as trickling filters, or RBC (NOLDE 1996). The advantage of all these systems is that they are compact (i.e. in densely populated urban settings) and that they efficiently reduce organic matter (JENSSEN 2004). However, they are high-tech and generally require skilled staff for construction as well as for operation.

RBC can treat domestic black- or greywater and any other low- or high-strength biodegradable wastewater (e.g. industrial wastewater from food processors or paper mills). They have been found to be particularly effective for decentralised applications (on the level of a small to medium community or industry/institution), where electricity and skilled staff are available (METCALF & EDDY Inc. 2003).

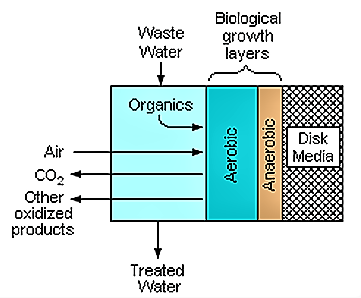

Treatment Process and Basic Design Principles

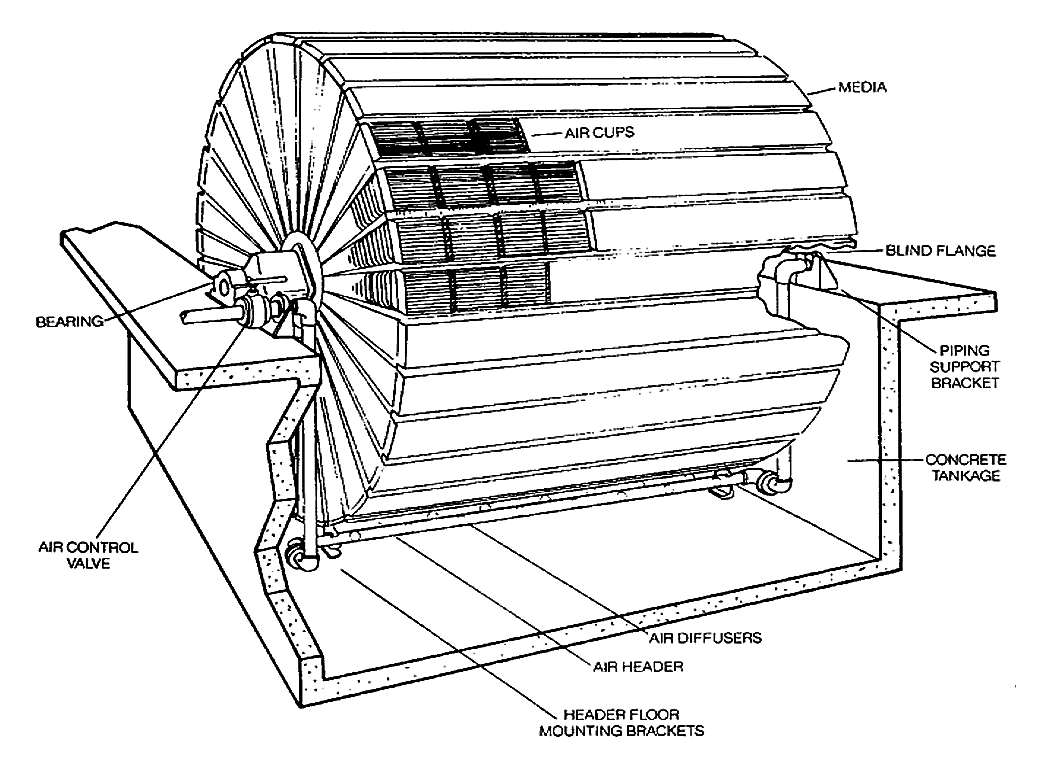

A series of circular lightweight rotating discs are mounted on a shaft through which wastewater flows. The partially submerged discs rotate through the wastewater slowly. The disks are most commonly made of high-density plastic sheets (e.g. Polyethylene, polystyrene or polyvinylchloride) and are usually ridged, corrugated, or lattice-like to increase the specific surface area (NSFC 2004). The surface of the disks provides an attachment site for bacteria and as the discs rotate, a film of biomass grows on their surfaces (NSFC 2004; WSP 2008). This biofilm is alternately exposed to either the air or the wastewater as it rotates. The oxygen necessary for the growth of these microorganisms is obtained by adsorption from the air as the biofilm on the disk is rotated out of the liquid (CRITES & TCHOBANOGLOUS 1998; SANIMAS 2005). As the biofilm passes through the liquid phase, nutrients and organic pollutants are taken up.

All oxygen, nutrients and organic pollutants are necessary for the growth of the microorganism and the conversion of the organic matter to CO2. Nitrogen is removed by nitrification and subsequent denitrification transforming it to gaseous N2, which is released to the air. The process is optimised by adjusting the speed of rotation and the depth of submergence (METCALF & EDDY Inc. 2003). In some designs, air is added to the bottom of the tank to provide additional oxygen in case of high-strength influents (CRITES & TCHOBANOGLOUS 1998).

The submerging level varies from 40 to 80 % (CRITES & TCHOBANOGLOUS 1998) and a usual rotating speed is 1 to 2 rpm (U.S.EPA 1980). The common disc diameter is between 0.6 and 3 m (SANIMAS 2005).

The degradation process is similar to the one in a trickling filter with a high rate of recirculation (CRITES & TCHOBANOGLOUS 1998). The higher contact time in RBCs due to rotation allows up to 8 to 10 times higher levels of treatment than in trickling filters (WSP 2008). Also because the rotation allows both optimum wetting and oxygen supply, RBCs are generally more reliable than other fixed-film processes. Additionally, the disc design is made in such a way that large amounts of biofilm can attach, which means that there is a large amount of biological mass present to degrade the pollutants (WSP 2007). The large amount of biomass and the stability of contact also results in an improved stability and a reduced susceptibility to changes in hydraulic or organic loading compared to conventional activated sludge processes (WSP 2007).

As for all fixed-film processes, primary settling and/or screening is required for the removal of grit, debris, and excessive oil (U.S. EPA 1980, WSP 2008). Such primary treatments are typically septic tanks, Imhoff tanks or anaerobic reactors. To remove sloughing sludge, a post-settling unit (i.e. a clarifier) is also required.

The performance of RBC systems depends on the design, the temperature, the concentration of the pollutants, the rotating velocity and the hydraulic retention time. RBCs can achieve biological oxygen demand (BOD) reductions of 80 to 90 % (SANIMAS 2005; WSP 2007; WSP 2008). The removal of nitrogen (which is mostly present as ammonia) by nitrification and subsequent denitrification is also high, because both aerobic nitrifying bacteria and anaerobic denitrifying bacteria can simultaneously live in the attached biofilm (HOCHHEIMER 1998), depending on weather they are situated on the bottom of the film, close to the disc support (and thus in anaerobic or anoxic conditions) or at the top of the film exposed to the air.

Some other microorganisms which can transform ammonia (NH3) in one single step to gaseous N2 under anaerobic conditions have also been discovered in biofilms growing on RBC. These bacteria were called annamox and resulted in the development of innovative aerobic ammonia removal and wastewater treatment processes.

Little is known about the removal of phosphorus in RBCs, but it can be presumed that large parts of the phosphorus present is either accumulated in the biofilm or in the settled and collected sludge.

RBCs can be arranged in a variety of ways depending on specific effluent characteristics and the secondary clarifier design (e.g. specifically for BOD removal or nitrification, NSFC 2004).

Excess biomass sloughs off the discs by the shearing forces exerted as the discs rotate, combined with the force of gravity (WSP 2008). The rotation movement helps to keep sloughed solids in suspension so they can be carried to a clarifier (gravity settler) for secondary settling. The collected sludge in the clarifier requires further treatment (WSP 2008) for stabilisation, such as anaerobic digestion, composting, constructed wetlands, ponds or drying. Very often in small installations, accumulated sludge is also directed back to the septic tank for storage and partial digestion (U.S.EPA 1980).

Effluents from RBC do not contain high levels of nutrients and are therefore not particularly interesting for agriculture, although they constitute a source of water. However, due to reduced removal of microorganisms (1 to 2 log units, U.S. EPA 2002), RBC effluents require a further treatment, such as sand filtration, constructed wetlands or another form of disinfection (e.g. chemical disinfection or UV disinfection).

RBCs are usually designed on the basis of hydraulic and organic loadings derived from pilot plants and other full-scale installation (WSP 2007). Hydraulic retention times (HRTs) generally lye within some hours up to two days.

Even though RBCs are resistant to shock loading, long-term high organic loading may cause anaerobic conditions, resulting in odour and poor treatment performance (U.S.EPA 1980).

Recirculation is not normally practised in package fixed-film systems since it adds to the degree of complexity and is energy and maintenance intensive. However, recirculation may be desirable in certain applications where minimum wetting rates are required for optimal performance (U.S.EPA 1980).

Units may be installed at or below ground depending upon site topography and other adjacent treatment processes. Access to all moving parts and controls is required, and proper venting of the units is paramount, especially if natural ventilation is being used to supply oxygen (U.S.EPA 1980).

RBCs are often covered with a fibreglass housing to protect the disks from sunlight, wind, rain and low temperatures as performance of RCS drops considerably at air temperatures below 12°C (U.S.EPA 2002; NSFC 2004).

Costs Considerations

Observed costs for RBCs are highly variable depending on climate and location. Generally, RBCs involve high capital costs as not all materials may be locally available and motor and special material for rotation is required. Another cost factor may be manufacture and implementation, which requires skilled experts (SANIMAS 2005).

Operation and maintenance costs are also relatively high, because operation requires a continuous electricity supply and supervision requires semi-skilled labour (U.S.EPA 1980) and professional operator (SANIMAS 2005).

Operation and Maintenance

During operation, the system must be supervised by professional operators (SANIMAS 2005). Maintenance includes lubrication of moving parts, motors and bearings; replacing seals, motors, servicing bearings; and cleaning the attached-growth media (spray-washing of discs and purging of settled sludge) (METCALF & EDDY Inc. 2003; WSP 2007). The discs may be also checked for debris accumulation, ponding and excessive or not sufficient biomass accumulation (U.S.EPA 2002).

Although fixed film units such as RBC and trickling filters are operation- and maintenance-intensive, they do not require seeding with bacterial cultures (as do anaerobic processes such as anaerobic baffled reactors, septic tanks, upflow anaerobic sludge blanket reactors or anaerobic digesters) and the start-up phase is therefore considerably shorter. However, it takes 6 to 12 weeks for the biofilm to establish for a good treatment performance (U.S.EPA 2002).

Health Aspects

For correct operation, RBCs are covered and thus protected from contact with humans or animals. However, excess sludge as well as the effluent require post-treatment to remove pathogenic microorganisms.

In any case (i.e. for operation and maintenance) direct contact with the biomass growing on the discs, the effluent or the sludge should be avoided.

For discharge or reuse, a treatment unit allowing further pathogen removal should be considered as mentioned above.

RBCs can achieve a high removal of biodegradable organic pollutants form domestic black- or greywater as well as from high-strength industrial wastewater (e.g. from dairies, bakeries, food processors, pulp, paper mills, WSP 2008).

A great variety of applications are known, either as post-treatment for activated sludge processes in conventional domestic wastewater treatment plants, or for decentralized application at the level of small to medium-sized communities, industries or institutions (WSP 2007; WSP 2008).

They are adapted for urban areas mostly: land requirements are low, but continuous and consequent energy supply as well as semi-skilled labour are indispensable.

Some of the material may be locally available, however, the system can only be planned and implemented by experts (SANIMAS 2005).

Small and Decentralized Wastewater Management Systems

Decentralised wastewater management presents a comprehensive approach to the design of both conventional and innovative systems for the treatment and disposal of wastewater or the reuse of treaded effluent. Smaller treatment plants, which are the concern of most new engineers, are the primary focus of this book.

CRITES, R. TCHOBANOGLOUS, G. (1998): Small and Decentralized Wastewater Management Systems. New York: The McGraw-Hill Companies IncOnsite Wastewater Treatment Systems Manual

Rather old design manual for onsite wastewater treatment options. However, valuable information on established systems such as septic tanks, sand filters, aerobic treatment units (suspended growth and fixed film), disinfection, nutrient removal as well as wastewater segregation and recycling are given. Additional information is given on disposal methods and appurtenances.

U.S.EPA (1980): Onsite Wastewater Treatment Systems Manual. (= EPA 625/1-80 , 12 ). United States Environmental Protection Agency, Office of Water Office of Research and DevelopmentSustainable Wastewater Management in Urban Areas

A document about sustainable wastewater management in urban areas.

JENSSEN, P.D. GREATOREX, J.M. WARNER, W. S. (2004): Sustainable Wastewater Management in Urban Areas. (= Kapitel 4. Kurs WH33, Konzeptionen dezentralisierter Abwasserreinigung und Stoffstrommanagement ). Hannover: University of HannoverWastewater Engineering, Treatment and Reuse

Greywater Reuse in Households – Experience from Germany. Environmental Research Forum

The Attached Growth Process – An old technology takes on new forms

The Pipeline Newsletter was formerly edited by the National Small Flows Clearinghouse (NSFC) and is now edited by the National Environmental Service Center based at the West Virginia University (USA). Popular with small community officials, citizens, maintenance and inspection personnel, and community educators, each quarterly issue of Pipeline focuses on a single wastewater topic and presents it in an easy-to-read format. This issues deals with attached-growth processes, including trickling filters, rotating biological contactors, sand filters, peat filters, textile filters and subsurface flow wetland.

NSFC (2004): The Attached Growth Process – An old technology takes on new forms. (= Pipeline , 1 / 15 ). Morgantown: National Small Flows Clearinghouse URL [Accessed: 22.04.2010]Informed Choice Catalogue

This informed choice catalogue for community based wastewater treatment technologies helps to identify suitable sanitation options and facilitates the assessment of different sanitation system components with regard to stakeholder preferences. A powerful tool for technical bottom-up planning giving overall information about technical options at a "glance".

SANIMAS (2005): Informed Choice Catalogue. pdf presentation. BORDA and USAID URL [Accessed: 29.05.2019]Philippines Sanitation Source Book and Decision Aid

This Sanitation Sourcebook distils some of the core concepts of sanitation in a user-friendly format so that the book can serve as a practical reference to sanitation professionals and investment decision-makers, particularly the local governments. The annexe contains a practical collection of factsheets on selected sanitation system options.

WSP (2007): Philippines Sanitation Source Book and Decision Aid. pdf presentation. Washington: Water and Sanitation Program (WSP). URL [Accessed: 01.06.2019]Technology Options for Urban Sanitation in India. A Guide to Decision-Making

These guidance notes are designed to provide state governments and urban local bodies with additional information on available technologies on sanitation. The notes also aid in making an informed choice and explain the suitability of approaches.

WSP (2008): Technology Options for Urban Sanitation in India. A Guide to Decision-Making. pdf presentation. New Delhi: Water and Sanitation Program (WSP) URL [Accessed: 03.06.2019]Onsite Wastewater Treatment Systems Manual Technology Fact Sheet 5. Fixed-Film Processes

Technical factsheet on aerobic fixed-film processes (trickling filters and rotating biological contactors). Applications, main design assumptions, performance and maintenance are discussed.

U.S.EPA (2002): Onsite Wastewater Treatment Systems Manual Technology Fact Sheet 5. Fixed-Film Processes. المُدخلات: U.S.EPA (1980): Onsite Wastewater Treatment Systems Manual. 008.Biological Filters: Trickling and RBC Design

The application of biological filters (fixed film processes) for the removal of ammonia from brackish or salt wastewaters from fish farms is discussed. The biological removal of ammonia in fixed-film processes is explained and design examples for ammonia removal in either trickling filters or rotating biological contactors are discussed.

HOCHHEIMER, J.N. WHETON, F.W. (1998): Biological Filters: Trickling and RBC Design. المُدخلات: LIBEY, G.S. ; TIMMONS, M.B. (1998): Proceedings of the Second International Conference on Recirculating Aquaculture Roanoke. Virginia: 291–318. URL [Accessed: 18.03.2010]Greywater recycling in Hotel Arabella Sheraton Am Buesing Palais Offenbach, Germany

This project aimed to reduce drinking water consumption and wastewater amount to be discharged to sewer through recycling greywater for internal re-use in a four star hotel in Germany. A new greywater biological treatment technology was trailed and demonstrated for the first time: Greywater from baths/showers in the guest rooms is separately collected and transferred to settling tanks. After preliminary sedimentation the greywater is treated continuously in a six-stage Rotating Biological Contactor (RBC) system.

GTZ (2006): Greywater recycling in Hotel Arabella Sheraton Am Buesing Palais Offenbach, Germany. (= data sheets for ecosan projects , 18 ). Eschborn: German Agency for Technical Cooperation (GTZ) URL [Accessed: 03.06.2019]Use of the Rotating Biological Contactor for Appropriate Technology Wastewater Treatment

Rotating biological contactors were assessed as an alternative to activated sludge processes for industrial wastewaters with high organic loadings, or for communities which are located far away from major treatment plants. The advantages claimed for RBCs over activated sludge processes were: simplicity of maintenance and operation, low power consumption, no flies or objectionable odours, ability to withstand shock or toxic loads and desirable sludge settling properties. A dynamic model and results of an experimental investigation are presented.

CHANG, T. STENSTROM, M.K. (1979): Use of the Rotating Biological Contactor for Appropriate Technology Wastewater Treatment. Los Angeles: Water Resources Program, School of Engineering and Applied Science University of California URL [Accessed: 18.03.2010]Onsite Wastewater Treatment Systems Manual Technology Fact Sheet 5. Fixed-Film Processes

Technical factsheet on aerobic fixed-film processes (trickling filters and rotating biological contactors). Applications, main design assumptions, performance and maintenance are discussed.

U.S.EPA (2002): Onsite Wastewater Treatment Systems Manual Technology Fact Sheet 5. Fixed-Film Processes. المُدخلات: U.S.EPA (1980): Onsite Wastewater Treatment Systems Manual. 008.The Attached Growth Process – An old technology takes on new forms

The Pipeline Newsletter was formerly edited by the National Small Flows Clearinghouse (NSFC) and is now edited by the National Environmental Service Center based at the West Virginia University (USA). Popular with small community officials, citizens, maintenance and inspection personnel, and community educators, each quarterly issue of Pipeline focuses on a single wastewater topic and presents it in an easy-to-read format. This issues deals with attached-growth processes, including trickling filters, rotating biological contactors, sand filters, peat filters, textile filters and subsurface flow wetland.

NSFC (2004): The Attached Growth Process – An old technology takes on new forms. (= Pipeline , 1 / 15 ). Morgantown: National Small Flows Clearinghouse URL [Accessed: 22.04.2010]Chapter 4. Wastewater Technologies

Comprehensive overview (in form of factsheets) on the different components of wastewater treatment systems (collection, transfer, onsite treatment, centralised and decentralised treatment, reuse, sludge management and disposal) adapted to the Caribbean Region. Industrial wastewater treatment is also discussed.

UNEP (2004): Chapter 4. Wastewater Technologies. المُدخلات: UNEP (2004): A Directory of Environmentally Sound Technologies for the Integrated Management of Solid, Liquid and Hazardous Waste for SIDS in the Caribbean Region. Nairobi: 63-125.Philippines Sanitation Source Book and Decision Aid

This Sanitation Sourcebook distils some of the core concepts of sanitation in a user-friendly format so that the book can serve as a practical reference to sanitation professionals and investment decision-makers, particularly the local governments. The annexe contains a practical collection of factsheets on selected sanitation system options.

WSP (2007): Philippines Sanitation Source Book and Decision Aid. pdf presentation. Washington: Water and Sanitation Program (WSP). URL [Accessed: 01.06.2019]Oeko-Technik-Park Hannover, Germany

This publication describes the operation and demonstration of environmentally sound technologies, reducing the consumption of water and targeting a closure of nutrient loops in a quarter of Hannover (including housings, a school, a church and industries). Environmental technology was combined with environmental education and awareness raising, particularly for the neighbourhood and the local youth. Applied technologies for the water cycle are: constructed wetlands, bio-reactors, mini wastewater treatment plant using rotating biological contactor technology for the greywater, rainwater reservoirs, urine diverting toilets, vacuum toilets, waterless urinals, and greywater evaporation beds. Further, block heat and solar power units were installed and ecological construction materials were used.

GTZ (2005): Oeko-Technik-Park Hannover, Germany. (= data sheets for ecosan projects , 7 ). Eschborn: German Agency for Technical Cooperation (GTZ) URL [Accessed: 03.06.2019]Greywater recycling in Hotel Arabella Sheraton Am Buesing Palais Offenbach, Germany

This project aimed to reduce drinking water consumption and wastewater amount to be discharged to sewer through recycling greywater for internal re-use in a four star hotel in Germany. A new greywater biological treatment technology was trailed and demonstrated for the first time: Greywater from baths/showers in the guest rooms is separately collected and transferred to settling tanks. After preliminary sedimentation the greywater is treated continuously in a six-stage Rotating Biological Contactor (RBC) system.

GTZ (2006): Greywater recycling in Hotel Arabella Sheraton Am Buesing Palais Offenbach, Germany. (= data sheets for ecosan projects , 18 ). Eschborn: German Agency for Technical Cooperation (GTZ) URL [Accessed: 03.06.2019]Potentials for greywater treatment and reuse in rural areas

Rotating biological contactors and constructed wetlands are best suited for greywater treatment. When greywater is reused, hygienic aspects have to be considered.

MUELLEGGER, E. ; LANGERGRABER, G. ; JUNG, H. ; STARKL, M. ; LABER, J. (2003): Potentials for greywater treatment and reuse in rural areas. المُدخلات: Proceedings of the 2nd international symposium on ecological sanitation – ecosan – closing the loop: Volume 1 , 799-802.Biological Filters: Trickling and RBC Design

The application of biological filters (fixed film processes) for the removal of ammonia from brackish or salt wastewaters from fish farms is discussed. The biological removal of ammonia in fixed-film processes is explained and design examples for ammonia removal in either trickling filters or rotating biological contactors are discussed.

HOCHHEIMER, J.N. WHETON, F.W. (1998): Biological Filters: Trickling and RBC Design. المُدخلات: LIBEY, G.S. ; TIMMONS, M.B. (1998): Proceedings of the Second International Conference on Recirculating Aquaculture Roanoke. Virginia: 291–318. URL [Accessed: 18.03.2010]Plant Loadings: Aerobic and Anaerobic Digestion and Types of Decomposition

The Mountain Empire Community College Water and Wastewater Distance Learning Course makes available all its documentation on the web. This section describes fixed film processes (including rotating biological contactors and trickling filters).

Other Biological Treatment Methods...

Different material on biological wastewater treatment (biofilm processes, trickling filters, Rotating Biological Contactors, Stabilization Ponds, Lagoon Systems, Oxidation Ditch, Advanced Treatment, Intermittent Sand Filters", Chemical Treatment and Imhoff Tank) available on the Tropak Homepage hosted by the Turkish Dokuz Eylul University in Izmir.