المُلخص التنفيذي

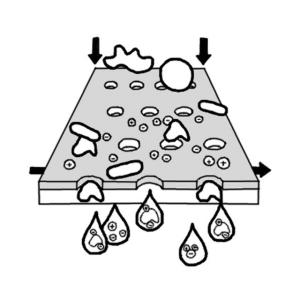

Membranes are thin and porous sheets of material able to separate contaminants from water when a driving force is applied. Once considered a viable technology only for desalination, membrane processes are increasingly employed in both drinking water and wastewater treatment for removal of bacteria and other microorganisms, particulate material, micropollutants, and natural organic material, which can impart colour, tastes, and odours to the water and react with disinfectants to form disinfection by-products (DBP). As advancements are made in membrane production and module design, capital and operating costs continue to decline.

| المُدخلات | المُخرَجات |

|---|---|

Drinking Water |

Introduction

Membranes emerged as a viable means of water purification in the 1960s with the development of high performance synthetic membranes. Implementation of membranes for water treatment has progressed using more advanced membranes made from new materials and employed in various configurations. An increasing scarcity in fresh water sources fuelled a push towards alternative resources such as ocean water.

Membranes are becoming increasingly popular for production of potable drinking water from ground, surface and seawater sources, as well as for the advanced treatment of wastewater and desalination.

Membrane modules

Adapted from SAGLE & FREEMAN (2004)

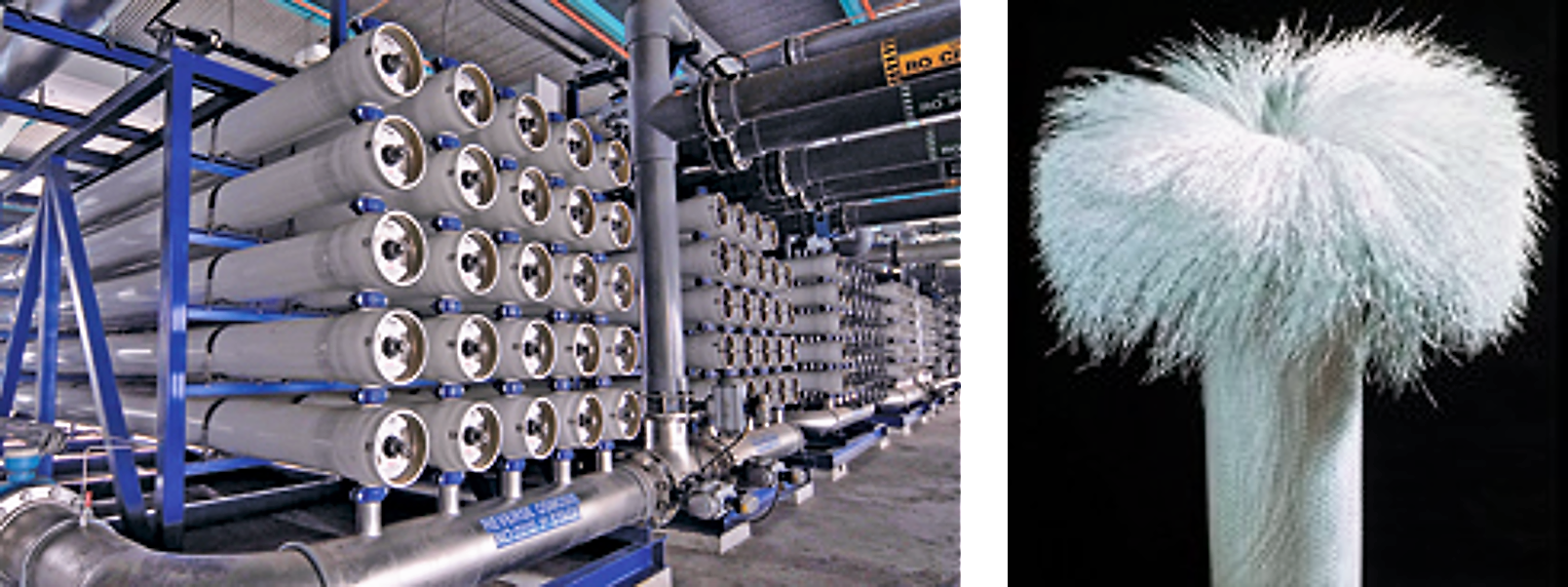

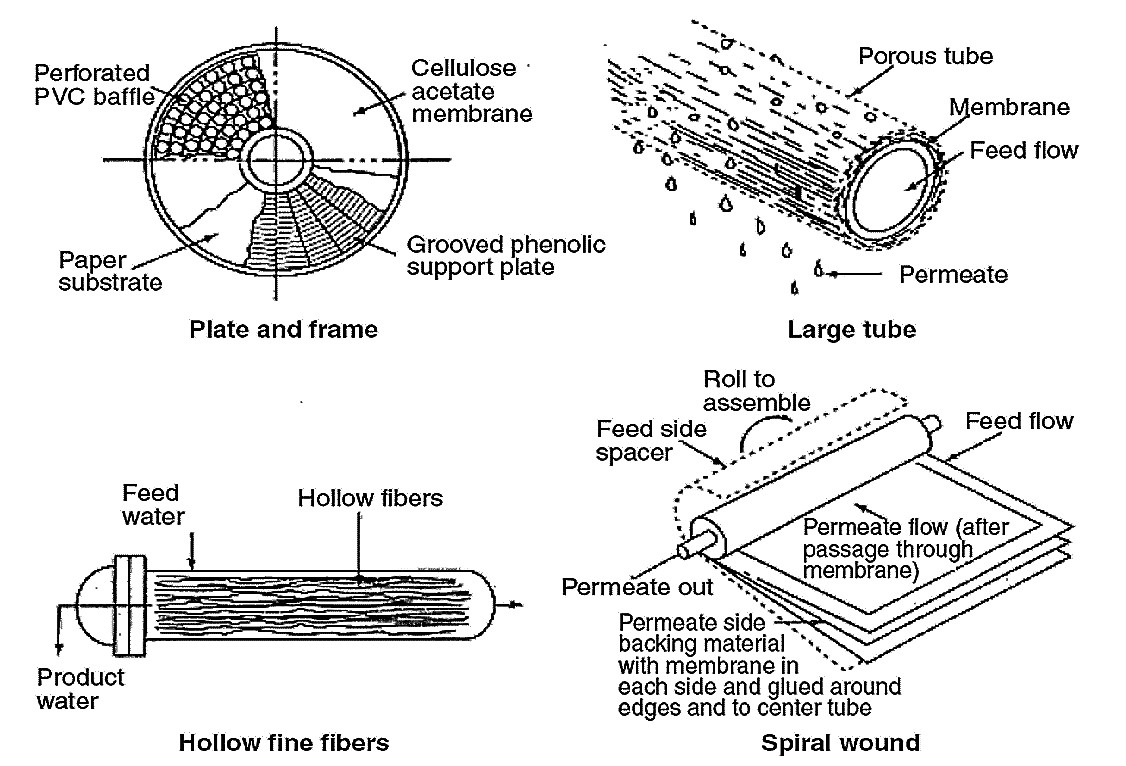

There are four main types of modules: plate-and-frame, tubular, spiral wound, and hollow fibre. The plate-and-frame module is the simplest configuration, consisting of two end plates, the flat sheet membrane, and spacers. In tubular modules, the membrane is often on the inside of a tube, and the feed solution is pumped through the tube. The most popular module in industry for nanofiltration or reverse osmosis membranes is the spiral wound module. This module has a flat sheet membrane wrapped around a perforated permeate collection tube. The feed flows on one side of the membrane. Permeate is collected on the other side of the membrane and spirals in towards the centre collection tube.

Hollow fibre modules used for seawater desalination consist of bundles of hollow fibres in a pressure vessel. They can have a shell-side feed configuration where the feed passes along the outside of the fibres and exits the fibre ends. Hollow fibre modules can also be used in a bore-side feed configuration where the feed is circulated through the fibres. Hollow fibres employed for wastewater treatment and in membrane bioreactors are not always used in pressure vessels. Bundles of fibres can be suspended in the feed solution and the permeate is collected from one end of the fibres.

Types of membranes

Adapted from SAGLE & FREEMAN (2004)

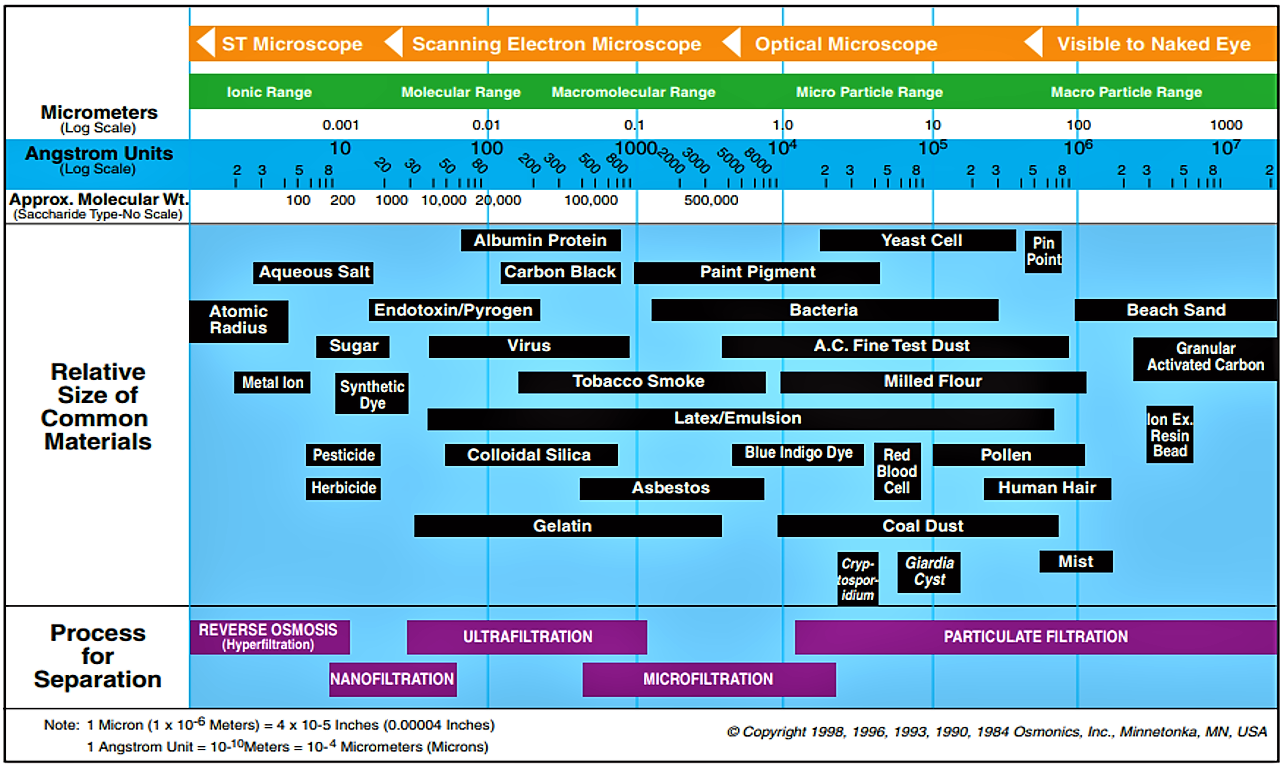

Water treatment processes employ several types of membranes. They include microfiltration (M-F), ultrafiltration (U-F), reverse osmosis (R-O), and nanofiltration (N-F) membranes. Microfiltration membranes have the largest pore size and typically reject large particles and various microorganisms. Ultrafiltration membranes have smaller pores than microfiltration membranes and therefore, in addition to large particles and microorganisms, they can reject bacteria and soluble macromolecules such as proteins. Reverse osmosis membranes are effectively non-porous and, therefore, exclude particles and even many low molar mass species such as salt ions, organics, etc. Nanofiltration membranes are relatively new and are sometimes called “loose” reverse osmosis membranes. They are porous membranes, but since the pores are on the order of ten angstroms or less, they exhibit performance between that of reverse osmosis and ultrafiltration membranes.

Membrane materials

Adapted from SAGLE & FREEMAN (2004)

Most membranes are synthetic organic polymers (e.g. polysulfone, cellulose acetate). Microfiltration and ultrafiltration membranes are often made from the same materials, but they are prepared under different membrane formation conditions so that different pore sizes are produced.

Membranes can also be prepared from inorganic materials such as ceramics or metals. Ceramic membranes are microporous, thermally stable, chemically resistant, and often used for microfiltration. However, disadvantages such as high cost and mechanical fragility have hindered their widespread use. Metallic membranes are often made of stainless steel and can be very finely porous. Their main application is in gas separations, but they can also be used for water filtration at high temperatures or as a membrane support.

The current tendency on membrane development is to use nanofunctionalised membranes. Polymer membranes doped with silver nanoparticles to avoid biofouling is an example of such modern membranes (PRONK 2011).

Membrane fouling

Adapted from WIKIPEDIA (2012)

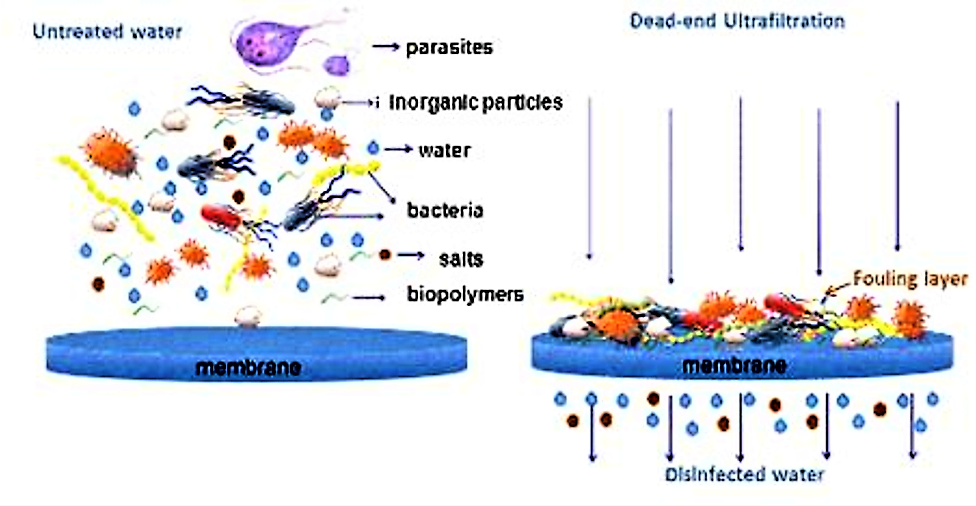

Membrane fouling is a process where solute or particles deposit onto amembrane surface or into membrane pores in a way that degrades the membrane's performance. It is a major obstacle to the widespread use of this technology. Membrane fouling can cause severe flux decline and affect the quality of the water produced. Severe fouling may require intense chemical cleaning or membrane replacement. This increases the operating costs of a treatment plant. There are various types of poulants: colloidal (clays, flocs), biological (bacteria, fungi), organic (oils, polyelectrolytes, humics) and scaling (mineral precipitates).

Fouling can be divided into reversible and irreversible fouling based on the attachment strength of particles to the membrane surface. Reversible fouling can be removed by a strong shear force of backwashing. Formation of a strong matrix of fouling layer with the solute during a continuous filtration process will result in reversible fouling being transformed into an irreversible fouling layer. Irreversible fouling is the strong attachment of particles, which cannot be removed by physical cleaning.

Example of simple decentralised system: gravity-driven membrane technology

Adapted from HOA (2009)

Eawag, KWB and Opalium conceived a membrane-based small-scale system that can operate without crossflow, backflush, aeration or chemical cleaning. Equipped with a biosand filter as pretreatment, it is designed to be robust, energy-sufficient (gravity-driven) and run with restricted chemical intervention (only residual chlorine). As a sole operational requirement, the membrane reactor is simply to be emptied on daily to weekly basis to superficially remove the material retained by the membrane and accumulated in the module. Otherwise, the system, which is only driven by a 40 cm differential pressure head (i.e. 40 mbar), is totally self-sustained and autonomous.

Operation and maintenance

Adapted from AMTA (2007)

Raw water quality must be reviewed frequently and operational parameters of the membrane treatment train should be continually trended and compared to original start up conditions. Pretreatment efficiencies and post treatment works should also be monitored closely. These tasks can alert operators of pending problems in time for corrective action to occur before production capabilities are impacted. While some changes in the treatment process may not significantly impact plant productivity or finished water quality, they may result in membrane degradation, more frequent cleaning, and generally higher operating costs over time if not properly addressed.

When treatment or equipment failures become apparent, it is critical that adequate maintenance resources are made available. As with any industrial facility, routine preventive maintenance activities should be performed prudently as scheduled, while responsiveness to unforeseen repairs also needs to be timely. Unlike other treatment technologies, which produce lower quality product as the raw water quality degrades, membrane systems produce consistent water quality while the systems themselves degrade.

Therefore, early detection of raw water changes and making adjustments to the operational parameters to accommodate the changes are the key to successful plant operation. A well-designed plant should include the necessary “tools” and have proper and adequate provisions for conducting routine tests and inspections. Such provisions include a well-equipped laboratory, tools and provisions for testing, and sample points for profiling.

Costs

Membrane filtration systems’ capital costs, on a basis of dollars per volume of installed treatment capacity, do not escalate rapidly as plant size decreases. This factor makes membranes quite attractive for small systems. In addition, for groundwater sources that do not need pretreatment, membrane technologies are relatively simple to install, and the systems require little more than a feed pump, a cleaning pump, the membrane modules, and some holding tanks.

At a glance

| Working principle | Pollutants are separated as water is forced to pass through the membrane. |

| Capacity/adequacy | Simple but high-tech. |

| Performance | Excellent separation capacity. |

| Costs | Relatively low operation costs. |

| Self-help compatibility | Process can be automatised but operators required for the control. |

| O&M | Membranes have to be backwashed on a regular basis to avoid fouling and to increase their lifetime. |

| Reliability | Reliable when membranes are maintained properly (backwashing). |

| Main strength | High performance and simple. |

| Main weakness | Membrane fouling, which implies backwashing operation or membrane replacement. |

Membrane processes have become more attractive for potable water production and advanced wastewater treatment in recent years due to the increased stringency of regulations, water scarcity, and decreasing costs of membranes. Membrane processes have excellent separation capabilities and show promise for meeting many of the existing and anticipated drinking water standards (TECHBRIEF 1999).

Membrane processes are very versatile: for example ultrafiltration and microfiltration are efficient for turbidity suspended particles and microbial removal, nanofiltration and ultrafiltration membranes for organics (e.g. DBP precursors, micropollutants) and viruses separation, and reverse osmosis process for desalination and removal of small size organic contaminants.

Operation and Maintenance of Membrane Facilities

Project: Gravity-Driven Membrane (GDM) Technology

Scaled-up trials with a gravity-driven ultrafiltration unit in France. Report within WP2.5: Compact Units for Decentralised Water Supply

Membrane Processes

Nanofiltration and Nanofunctionalised Membranes State of Art and Examples of Application

Application of Membrane Technology to the Production of Drinking Water

Filtering Out the Bad Stuff

Fundamentals of Membranes for Water Treatment

Advanced Filtration

Membrane Filtration

This factsheet covers several membrane filtration techniques: microfiltration, ultrafiltration, nanofiltration and reverse osmosis and also contains a membrane process selection chart.

TECHBRIEF (1999): Membrane Filtration. Morgantown, WV: National Drinking Water Clearing House URL [Accessed: 21.05.2012]Membrane Fouling

A Brief Overview of Reverse Osmosis Membrane Technology

Ceramic Membranes for Environmental Related Applications

This paper describes the developments of ceramic membranes and their application in solvent recovery and drinking water treatment.

CIORA, R. ; IIU, P. K. T. (2008): Ceramic Membranes for Environmental Related Applications. المُدخلات: Fluid/ Particles Separation Journal : Volume 15 , 51-60. URL [Accessed: 24.10.2012]Process Water Production from River Water by Ultrafiltration and Reverse Osmosis

This document is about the combination of ultrafiltration and reverse osmosis for the production of deionised water from surface waters.

CLEVER, M. ; JORDT, F. ; KNAUF, R. ; RABIGER, N. ; RUDEBUSCH, M. ; HILKER-SCHEIBEL, R. (2000): Process Water Production from River Water by Ultrafiltration and Reverse Osmosis . المُدخلات: Desalination: Volume 131 , 325-336. URL [Accessed: 22.05.2019]Pilot Study of Integrated MF-based MBR and UF for Drinking Water Producing by Treating Micropolluted Source Water

This publication describes a green process based on a double membrane technology combining a microfiltration based membrane bioreactor and ultrafiltration to treat micro-polluted source water in drinking water treatment.

GAO, W. ; LIANG, H. ; WANG, L.Y. ; CHANG, H.Q. ; LI, G.B. (2011): Pilot Study of Integrated MF-based MBR and UF for Drinking Water Producing by Treating Micropolluted Source Water . المُدخلات: 2011 2nd International Conference on Chemistry and Chemical Engineering IPCBEE : Volume 14Membrane Filtration

This factsheet covers several membrane filtration techniques: microfiltration, ultrafiltration, nanofiltration and reverse osmosis and also contains a membrane process selection chart.

TECHBRIEF (1999): Membrane Filtration. Morgantown, WV: National Drinking Water Clearing House URL [Accessed: 21.05.2012]Nanofiltration in Drinking Water Treatment

This report presents a literature review on nanofiltration.

THORSEN, T. FLOGSTAD, H. (2006): Nanofiltration in Drinking Water Treatment. Nieuwegein, The Netherlands: Techneau URL [Accessed: 22.05.2019]Membrane Systems for the Fight against Water-Borne Contaminants in Small Communities and Remote Areas from the Developing World: Accomplishments in Thailand and Some New Development in Sénégal and Mali

This article outlines some key features of these membrane-based technologies and describes how they can be adapted to supply safe drinking water in remote communities and rural regions from the developing world.

FARCY, M. ; DOUCOURE, A. (2010): Membrane Systems for the Fight against Water-Borne Contaminants in Small Communities and Remote Areas from the Developing World: Accomplishments in Thailand and Some New Development in Sénégal and Mali . المُدخلات: The Open Biology Journal: Volume 3 , 74-80. URL [Accessed: 22.05.2019]Evaluating Membrane Processes for Drinking Water Treatment Design

This case study outlines the activities of an engineering consulting firm that has been contracted to submit a preliminary design for a new water treatment plant for a rural community in Nova Scotia, Canada.

WALSH, M.E. GAGNON, G.A. (2006): Evaluating Membrane Processes for Drinking Water Treatment Design. Halifax, Canada: Association of Environmental Engineering & Science Professors URL [Accessed: 22.05.2019]Membrane Filtration Guidance Manual

This manual from EPA provides technical information on the use of membrane filtration and application of the technology.

EPA (2005): Membrane Filtration Guidance Manual. Washington D.C.: Environmental Protection Agency (EPA) URL [Accessed: 22.05.2019]Membrane Separation

Design Considerations for Small Drinking Water Membrane Systems

Microfiltration membrane technology provides a unique design solution for small communities (up to 10 000 people). This is especially true in remote locations where space and personnel are limited and where environmental considerations restrict or prohibit chemical and/or sludge disposal.

WACHINSKI, A.M. LIU, C. (2007): Design Considerations for Small Drinking Water Membrane Systems. Tucson, AZ: Water Conditioning & Purification Magazine URL [Accessed: 22.05.2019]Advancing the Science of Water: AwwaRF and Membrane Processes

This document describes the use of membranes in removing pathogens, other particles, and organic matter from traditional supplies; desalting lower-quality sources such as brackish groundwater and seawater; and treating municipal water wastewater for non-potable use.

AWWA RF (2007): Advancing the Science of Water: AwwaRF and Membrane Processes. Denver, CO: American Water Works Association Research Foundation (AWWA RF). [Accessed: 08.03.2012] PDFMembrane Technologies for Water Applications. Highlights from a selection of European research projects

This document summarises main advancements performed within European projects in the field of membrane technologies for water treatment

EC (2010): Membrane Technologies for Water Applications. Highlights from a selection of European research projects. Brussels: European Commission (EC) URL [Accessed: 22.05.2019]Gravity-Driven Membrane (GDM) technology

Read more about EAWAGs Gravity-Driven Membrane (GDM) technology project. There also downloads available.

Membrane Processes

This website provides an introduction of membrane processes including microfiltration nanofiltration, and ultrafiltration.

Aqua Membranes

This webpage of Aqua Membranes presents the change of the membrane filtration industry with its unique three-dimensional Printed Spacer Technology.