Executive Summary

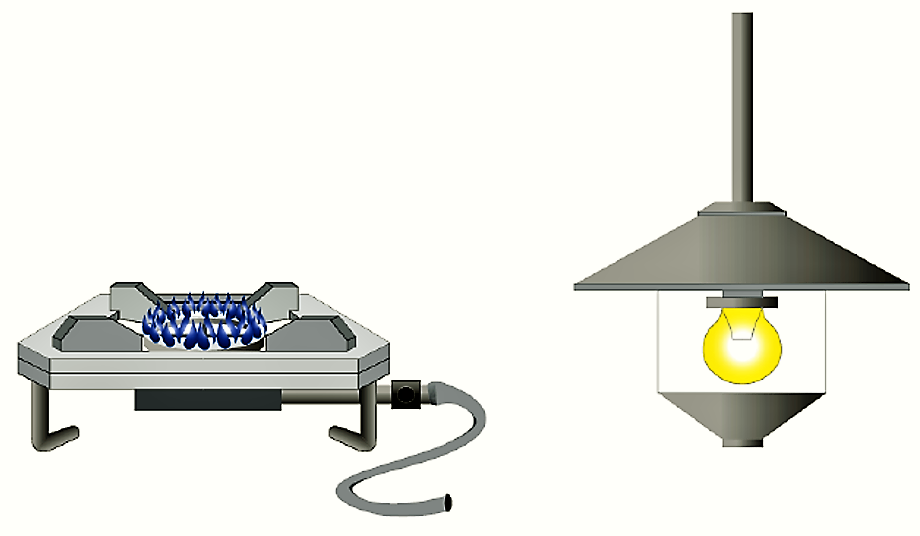

In principal, biogas can be used like other fuel gas. When produced in household-level biogas reactors, it is most suitable for cooking. Additionally, electricity generation is a valuable option with the biogas produced in large anaerobic digesters.

| In | Out |

|---|---|

| Biogas |

Food Products, Energy |

Introduction

Household energy demand varies greatly and is influenced by cooking and eating habits (i.e., hard grains and maize may require substantial cooking times, and, therefore, more energy compared to cooking fresh vegetables and meat). Biogas has an average methane content of 55-75%, which implies an energy content of 6-6.5 kWh/m3.

Design Considerations

Gas demand can be defined on the basis of energy previously consumed. For example, 1 kg firewood roughly corresponds to 200 L biogas, 1 kg dried cow dung corresponds to 100 L biogas and 1 kg charcoal corresponds to 500 L biogas.

Gas consumption for cooking per person and per meal is between 150 and 300 L biogas. Approximately 30-40 L biogas is required to cook one litre of water, 120-140 L for 0.5 kg rice and 160-190 L for 0.5 kg vegetables.

Tests in Nepal and Tanzania have shown that the consumption rate of a household biogas stove is about 300-400 L/h. However, this depends on the stove design and the methane content of the biogas.

The following consumption rates in litres per hour (L/h) can be assumed for the use of biogas:

- household burners: 200-450 L/h

- industrial burners: 1000-3000 L/h

- refrigerator (100 L) depending on outside temperature: 30-75 L/h

- gas lamp, equivalent to a 60 W bulb: 120-150 L/h

- biogas/dieselengine per bhp: 420 L/h

- generation of 1 kWh of electricity with biogas/diesel mixture: 700 L/h

- plastics moulding press (15 g, 100 units) with biogas/diesel mixture: 140 L/h

Compared to other gases, biogas needs less air for combustion. Therefore, conventional gas appliances need to be modified when they are used for biogas combustion (e.g., larger gas jets and burner holes).

The distance through which the gas must travel should be minimized since losses and leakages may occur. Drip valves should be installed for the drainage of condensed water, which accumulates at the lowest points of the gas pipe.

Health Aspects/Acceptance

In general, users enjoy cooking with biogas as it can immediately be switched on and off (as compared to wood and coal). Also, it burns without smoke, and, thus, does not lead to indoor air pollution. Biogas generated from faeces may not be appropriate in all cultural contexts. Assuming that the biogas plant is well-constructed, operated and maintained (e.g. water is drained), the risk of leaks, explosions or any other threats to human health is negligible.

Operation & Maintenance

Biogas is usually fully saturated with water vapour, which leads to condensation. To prevent blocking and corrosion, the accumulated water has to be periodically emptied from the installed water traps. The gas pipelines, fittings and appliances must be regularly monitored by trained personnel.

When using biogas for an engine, it is necessary to first reduce the hydrogen sulphide because it forms corrosive acids when combined with condensing water.

The reduction of the carbon-dioxide content requires additional operational and financial efforts. As CO2 "scrubbing" is not necessary when biogas is used for cooking, it is rarely advisable in developing countries.

The calorific efficiency of using biogas is 55% in stoves, 24% in engines, but only 3% in lamps. A biogas lamp is only half as efficient as a kerosene lamp. The most efficient way of using biogas is in a heat-power combination where 88% efficiency can be reached. But this is only valid for larger installations and under the condition that the exhaust heat is profitably used. For household application, the best way to use biogas is cooking.

Biogas from Waste and Renewable Resources, 2nd Ed

Biogas Digest Volume II

This information service on biogas technology has been developed and produced on the order of the GTZ project Information and Advisory Service on Appropriate Technology (ISAT). It contains information on the application of biogas and product development.

KOSSMANN, W. POENITZ, U. HABERMEHL, S. HOERZ, T. KRAEMER, P. KLINGLER, B. KELLNER, C. WITTUR, T. VON KLOPOTEK, F. KRIEG, A. EULER, H. (1999): Biogas Digest Volume II. Biogas - Application and Product Development. Eschborn: GTZ URL [Accessed: 27.05.2019]Research on Anaerobic Digestion of Organic Solid Waste at Household Level in Dar es Salaam, Tanzania

Decentralized anaerobic digestion is a promising technology to handle the large organic fraction of the municipal solid waste (e.g. kitchen waste) with the additional benefit of producing biogas as well as fertilizer. This paper evaluates the suitability of the ARTI Compact biogas system as a decentralised low-tech treatment option for the organic fraction of household waste in Dar es Salaam, Tanzania.

LOHRI (2009): Research on Anaerobic Digestion of Organic Solid Waste at Household Level in Dar es Salaam, Tanzania. (= Bachelor Thesis ). Zurich University of Applied Sciences (ZHAW) URL [Accessed: 27.05.2019]Evaluation of Biogas Sanitation Systems in Nepalese Prisons. Summary Presentation of Evaluation Results

10 to 20m3 biogas digesters were installed in three different prisons and fed with human excreta and kitchen waste. Pathogen requirement were only partially fulfilled and slurry application as fertilizer needs further investigation and promotion.

EAWAG ; SANDEC (2009): Evaluation of Biogas Sanitation Systems in Nepalese Prisons. Summary Presentation of Evaluation Results. Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC). [Accessed: 27.04.2010] PDFTechnology Review of Biogas Sanitation

This document provides an overview and introduction on biogas sanitation (anaerobic digestion) for blackwater or for brown water, or excreta treatment for reuse in developing countries. The main technologies discussed are biogas settlers (BSs), biogas septic tanks, anaerobic baffled reactor (ABRs), anaerobic filter (AFs) and upflow anaerobic sludge blanket reactors (UASBs).

MANG, H.-P. LI, Z. (2010): Technology Review of Biogas Sanitation. (= Technology Review ). Eschborn: Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH URL [Accessed: 26.05.2019]Anaerobic Digestion of Biowaste in Developing Countries

This book published by Eawag/Sandec compiles existing and recently generated knowledge on anaerobic digestion of urban biowaste at small and medium scale with special consideration given to the conditions prevailing in developing countries. Written for actors working in the waste and renewable energy sector, the book is divided into two parts: Part 1 focuses on practical information related to the anaerobic digestion supply chain (substrate-, process-, and product chain), and Part 2 presents selected case studies from around the world.

VOEGELI, Y. LOHRI, C.R. GALLARDO, A. DIENER, S. ZURBRUEGG, C. EAWAG (2014): Anaerobic Digestion of Biowaste in Developing Countries. Practical Information and Case Studies. Duebendorf: Swiss Federal Institute of Aquatic Science and Technology (Eawag) URL [Accessed: 28.05.2019]