Executive Summary

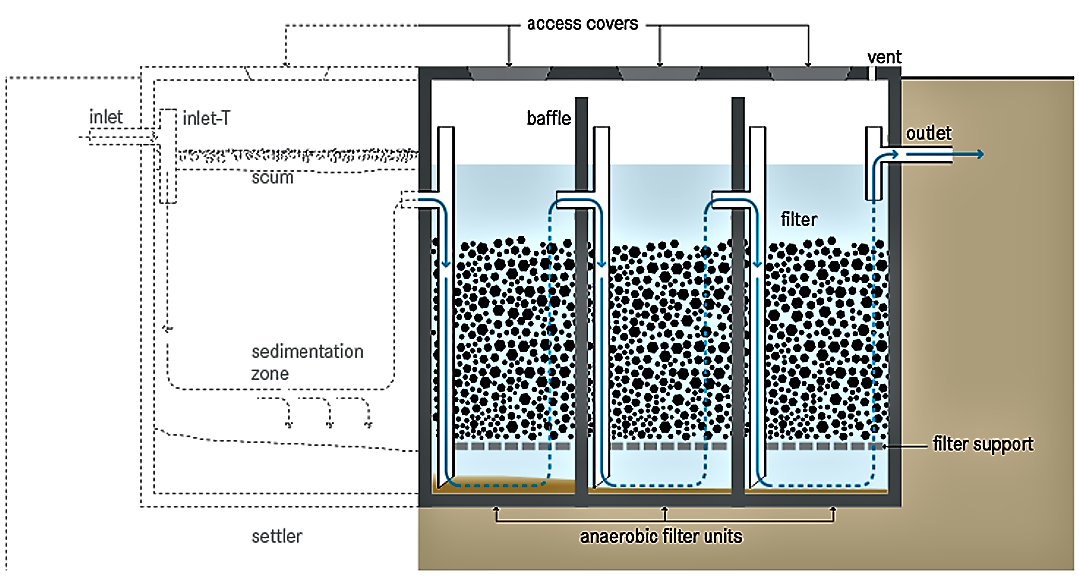

An anaerobic filter is a fixed-bed biological reactor with one or more filtration chambers in series. As wastewater flows through the filter, particles are trapped and organic matter is degraded by the active biomass that is attached to the surface of the filter material.

| In | Out |

|---|---|

| Blackwater, Greywater, Brownwater, (Faecal Sludge) |

Fertigation Water, Biogas, Compost/Biosolids |

Introduction

With this technology, suspended solids and BOD removal can be as high as 90%, but is typically between 50% and 80%. Nitrogen removal is limited and normally does not exceed 15% in terms of total nitrogen (TN).

Design Considerations

Pre- and primary treatment is essential to remove solids and garbage that may clog the filter. The majority of settleable solids are removed in a sedimentation chamber in front of the anaerobic filter. Small-scale stand-alone units typically have an integrated settling compartment, but primary sedimentation can also take place in a separate Settler or another preceding technology (e.g., existing Septic Tanks). Designs without a settling compartment are of particular interest for (Semi-) Centralized Treatment plants that combine the anaerobic filter with other technologies, such as the Anaerobic Baffled Reactor (ABR).

Anaerobic filters are usually operated in upflow mode because there is less risk that the fixed biomass will be washed out. The water level should cover the filter media by at least 0.3 m to guarantee an even flow regime. The hydraulic retention time (HRT) is the most important design parameter influencing filter performance. An HRT of 12 to 36 hours is recommended.

The ideal filter should have a large surface area for bacteria to grow, with pores large enough to prevent clogging. The surface area ensures increased contact between the organic matter and the attached biomass that effectively degrades it. Ideally, the material should provide between 90 to 300 m2 of surface area per m3 of occupied reactor volume. Typical filter material sizes range from 12 to 55 mm in diameter. Materials commonly used include gravel, crushed rocks or bricks, cinder, pumice, or specially formed plastic pieces, depending on local availability.

The connection between the chambers can be designed either with vertical pipes or baffles. Accessibility to all chambers (through access ports) is necessary for maintenance. The tank should be vented to allow for controlled release of odorous and potentially harmful gases.

Health Aspects/Acceptance

Under normal operating conditions, users do not come in contact with the influent or effluent. Effluent, scum and sludge must be handled with care as they contain high levels of pathogenic organisms. The effluent contains odorous compounds that may have to be removed in a further polishing step. Care should be taken to design and locate the facility such that odours do not bother community members.

Operation & Maintenance

An anaerobic filter requires a start-up period of 6 to 9 months to reach full treatment capacity since the slow growing anaerobic biomass first needs to be established on the filter media. To reduce start-up time, the filter can be inoculated with anaerobic bacteria, e.g., by spraying septic tank sludge onto the filter material. The flow should be gradually increased over time. Because of the delicate ecology, care should be taken not to discharge harsh chemicals into the anaerobic filter.

Scum and sludge levels need to be monitored to ensure that the tank is functioning well. Over time, solids will clog the pores of the filter. As well, the growing bacterial mass will become too thick, break off and eventually clog pores. When the efficiency decreases, the filter must be cleaned. This is done by running the system in reverse mode (backwashing) or by removing and cleaning the filter material.

Anaerobic filter tanks should be checked from time to time to ensure that they are watertight.

This technology is easily adaptable and can be applied at the household level, in small neighbourhoods or even in bigger catchment areas. It is most appropriate where a relatively constant amount of blackwater is generated. The anaerobic filter can be used for secondary treatment, to reduce the organic loading rate for a subsequent aerobic treatment step, or for polishing.

This technology is suitable for areas where land may be limited since the tank is most commonly installed underground and requires a small area. Accessibility by vacuum truck is important for desludging.

Anaerobic filters can be installed in every type of climate, although the efficiency is lower in colder climates. They are not efficient at removing nutrients and pathogens. Depending on the filter material, however, complete removal of worm eggs may be achieved. The effluent usually requires further treatment.

Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods

This report compiles international experience in greywater management on household and neighbourhood level in low and middle-income countries. The documented systems, which vary significantly in terms of complexity, performance and costs, range from simple systems for single-house applications (e.g. local infiltration or garden irrigation) to rather complex treatment trains for neighbourhoods (e.g. series of vertical and horizontal-flow planted soil filters).

MOREL, A. DIENER, S. (2006): Greywater Management in Low and Middle-Income Countries, Review of Different Treatment Systems for Households or Neighbourhoods. (= SANDEC Report No. 14/06 ). Duebendorf: Swiss Federal Institute of Aquatic Science (EAWAG), Department of Water and Sanitation in Developing Countries (SANDEC) URL [Accessed: 27.05.2019]Biological Wastewater Treatment in Warm Climate Regions Volume 1

Biological Wastewater Treatment in Warm Climate Regions gives a state-of-the-art presentation of the science and technology of biological wastewater treatment, particularly domestic sewage. The book covers the main treatment processes used worldwide with wastewater treatment in warm climate regions given a particular emphasis where simple, affordable and sustainable solutions are required. The 55 chapters are divided into 7 parts over two volumes: Volume One: (1) Introduction to wastewater characteristics, treatment and disposal; (2) Basic principles of wastewater treatment; (3) Stabilisation ponds; (4) Anaerobic reactors; Volume Two (also available in the SSWM library): (5) Activated sludge; (6) Aerobic biofilm reactors; (7) Sludge treatment and disposal.

SPERLING, M. von LEMOS CHERNICHARO, C.A. de (2005): Biological Wastewater Treatment in Warm Climate Regions Volume 1. London: International Water Association (IWA) Publishing URL [Accessed: 26.05.2019]