Executive Summary

This case study supports and illustrates the theoretic factsheet "Distribution process: retailers or mobile salesforce" with practical insights.

Identifying distribution channels to grow - Scaling of SPOUTS of Water in Uganda

SPOUTS of Water is the local manufacturer and distributor of Purifaaya, an affordable (UGX 90,000 or US$ 25) and effective ceramic water filter, in Uganda, filtering out 99.9% of microbiological contaminants and greater than 99.99% E. coli reduction, greater than 94% turbidity reduction. SPOUTS was founded in 2010 noticing the lack of affordable local solutions for accessing clean drinking water. SPOUTS is determined to take a sustainable market-based approach providing access to clean water to the 38 million Ugandans in need by selling their locally produced ceramic water filter.

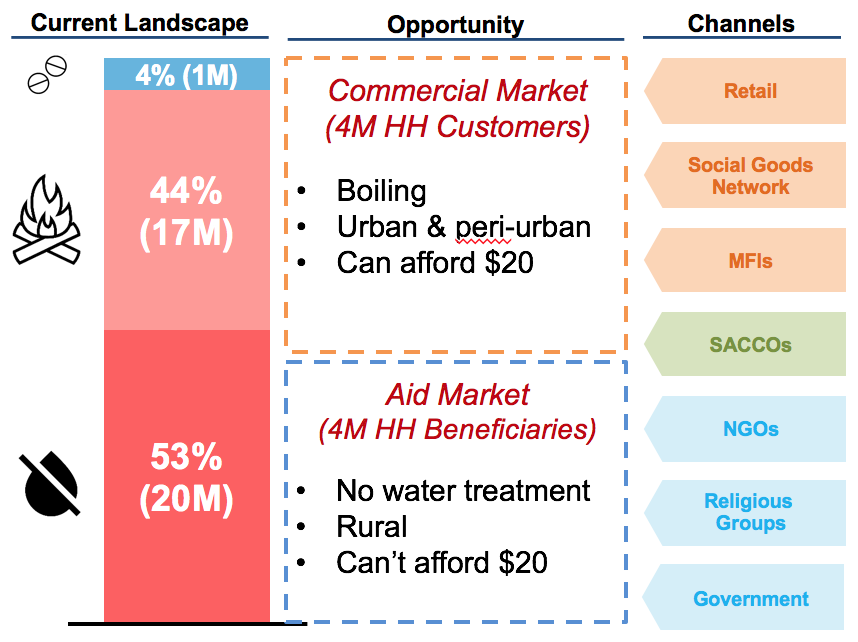

Early on, SPOUTS recognised that its strength not only lied in its local production of an affordable and much-needed product. Its ability to make sure that the products were getting to the right end-users was just as important in fulfilling its mission. To do so, SPOUTS used a tiered system that utilises different distribution methods dependent on the target audience (see figure below).

For high-income families, SPOUTS utilises local retail outlets to distribute the Purifaaya. These retail outlets make the filters available to families who don’t require financing plans. By leveraging local retail outlets and the respected business leaders who run them, SPOUTS builds increased trust in the Purifaaya. Retail partners include pharmacies, supermarkets, distributors of social goods (Living Goods, BRAC), etc. For middle and low-income families, SPOUTS works with SACCOs (local Savings and Credit Cooperatives) and micro-finance institutions (MFIs) (see factsheet on microfinance) to develop financing plans. SACCOs are an integral part of life in Uganda, providing saving and credit opportunities to its members. By leveraging these institutions, SPOUTS is able to seamlessly integrate its product into Ugandan culture (NUWAGABA, 2012).

SPOUTS, 2017

SPOUTS further differentiates itself in that it sells filters vs. gives them away for free. SPOUTS believes families who purchase filters are more likely to utilise them than families who receive filters for free (unless proper educational campaigns are carried out, which can be time and cost-intensive). Thus, SPOUTS not only effectively sells filters by utilising local distribution channels, but also ensures consistent usage of the filter by leveraging a for-profit model. However, while selling filters has been shown to increase usage, there are some individuals and organisations who simply cannot afford to purchase filters. These communities are served by aid partners, who then install the filters in public spaces and for the poorest families (e.g., schools, prisons, refugee settlements). There is also an NGO in the US related to SPOUTS of Water in order to receive donations and install filters in these areas as well.

Throughout this entire journey, SPOUTS has been met with the same challenges that many start-ups in developing countries face: unclear bureaucratic hurdles, differences in work culture, challenges in hiring, etc. However, many of the challenges associated with the thought process and manufacturing were addressed by looking to existing ceramic water filter manufacturers. While they might not have had the local context to provide Uganda-specific advice, these existing organizations helped guide SPOUTS to at least ask the right questions. By today more than 10,000 filters have been sold, encouraging the team to work hard to one day in the near future reach break-even.

Lessons learnt by SPOUTS in scaling up their distribution and manufacturing

Develop a set of best practices

From the beginning SPOUTS developed a set of best practices by reaching out to local SME’s, ceramic water filter manufacturers and other professionals. Not only did this avoid reinventing the wheel, digesting all the information and having it written down allowed for better transparency and easier hand-overs during changes in leadership (additional management arrived).

Leverage existing distribution networks

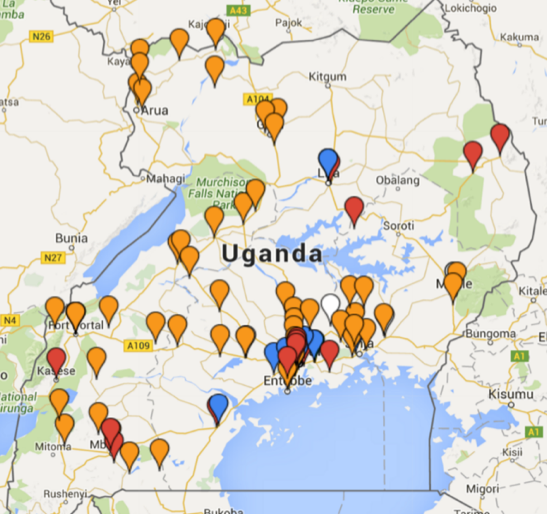

SPOUTS originally tried to set up its own distribution storefronts, however, quickly learnt that there were existing networks with much more experience and expertise. Working with them allowed SPOUTS to not only gain access to the broader Uganda market but also provided a level of credibility and trust to a new product on the market.

Generate trust in your product

Through local product certification processes, brand ambassadors, and experiential promotions, SPOUTS was able to garner trust in the product early on. Otherwise, given the unfamiliarity with filtration systems, SPOUTS would have had trouble gaining any traction.

Simultaneously target aid and for-profit channels

By working with aid partners and installing filters in public spaces the awareness for the product could be increased. Having free filters only in public places prevented the cannibalisation of the market due to free product distribution; this was an initial concern in terms of working within aid channels.

Recommendations for replication

Set up production, distribution, and corporate support locally

SPOUTS’ unique distribution model leverages an expert understanding of local business operations, and the effectiveness of SPOUTS manufacturing is driven by daily observation at the production site in Kampala. Being on the ground develops the local knowledge needed to succeed for any business, and especially for social enterprises.

Know your audience

Uganda’s longstanding use of clay pots to store water makes it uniquely positioned to adopt ceramic filters. Diving deeper, SPOUTS identified mothers as the primary target for purchasing filters; they are the decision makers, the providers for their family’s well-being. When developing marketing materials and consumer-facing content, SPOUTS has mothers in mind. These observations came from market research.

Utilise an AGILE approach

Utilising production and sales pilots has enabled SPOUTS to quickly test new ideas and identify what works and what doesn’t. Testing ideas with pilots before implementing at scale has accordingly allowed minimising the time and money spent on unsuccessful ideas.