Executive Summary

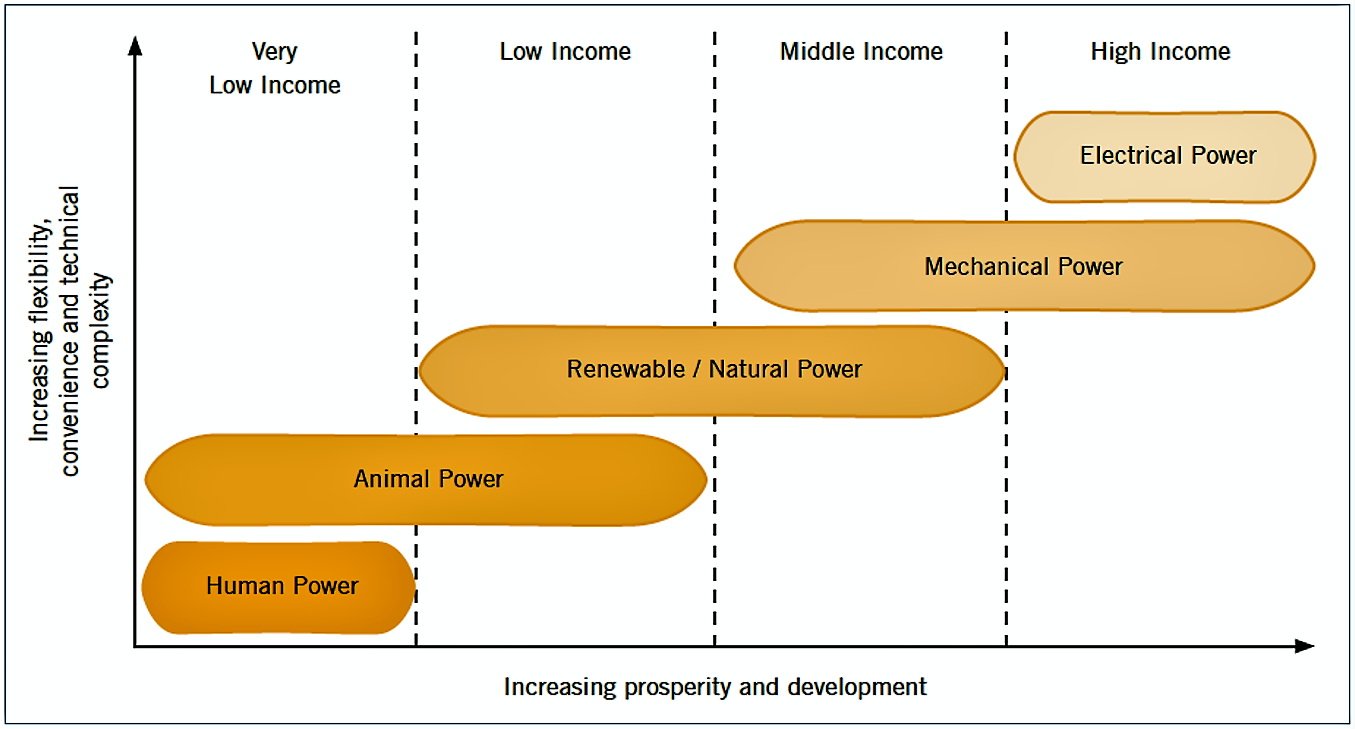

The force of water has been used for centuries to produce mechanical power. In remote villages and among low-income regions around the world, daily activities such as agro/food processing and water pumping are possible due to mechanical power. Today, mechanical power contributes to increase the efficiency and effectiveness of productive activities aiming to meet basic human needs such as water supply access, natural resource extraction and small-scale manufacturing. Mechanical power can be considered as a sustainable source of energy services for low-income people since it does not require high investment costs.

| In | Out |

|---|---|

Freshwater, Energy |

Introduction

While water resources are valued for human health and for sustaining food production, the energy contained in moving water such as rivers or tides can also be harnessed to do work through mechanical devices, or to create energy in small scale or large scale hydropower schemes. Globally, 1.4 billion people lack access to electricity, with an additional 1 billion having only intermittent access (UNDP 2012). As running water is a resource that is globally available and renewable, harnessing its power for mechanical uses can improve livelihoods and increase working productivity even in rural or developing areas where no local electricity source is available.

How Does it Work?

Regardless of the technology used to use water for mechanical power, the principle of mechanical water use is the same: that the kinetic energy contained in flowing water can be harnessed and converted into mechanical energy in order to do work. The amount of energy that can be harvested depends on both the quantity of water flowing, and the velocity (speed) at which it flows.

There are many devices that can be implemented to use water for mechanical purposes. Some of the most important technologies are summarised below:

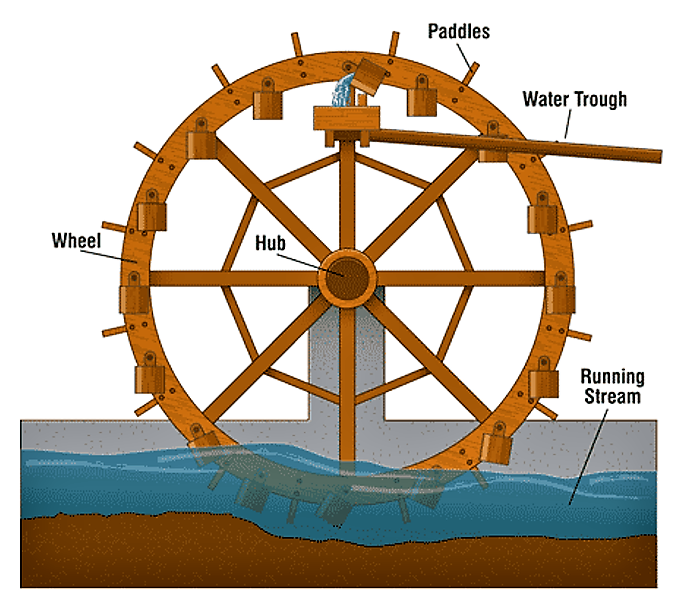

Water Wheels

Adapted from TRYENGINEERING (2011)

A water mill is a structure that uses a water wheel or turbine to drive a mechanical process. A water mill works by diverting water from a river or pond to a water wheel, usually along a channel or pipe. The water's force drives or pushes the blades of the wheel (or turbine), which then turns or rotates an axle that drives machinery that is attached to it to do work. This machinery performs a specific task, such as transporting water or milling flour. Waterwheels can either be horizontal or vertical with respect to water flow. Horizontal water wheels are simpler, but require high water velocities to work well. There are many types of water wheel. One type, called a noria (pictured right) is used to transport water from a running stream into a trough for local water supply.

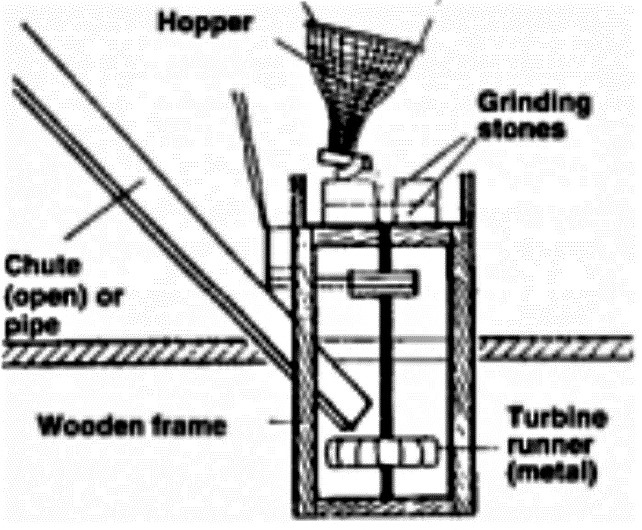

Water Mills and Improved Water Mills

A water mill is a water wheel or turbine that is connected to a device that drives a mechanical process. Water mills can be used for such purposes as grinding flour or agricultural produce, cutting up materials such as pulp or timber, or metal shaping. Traditional water mills are made from a wheel or turbine with wooden blades that turn when water runs through. The turbine or wheel then turns a grinder shaft, which is connected to a grinding stone.

Recently, improved water mills have been designed which replace wooden blades with metal, cup-shaped blades. This modification has led to a doubling of efficiency and operational capacity by over 100%. Improved water mills have been successfully used as a cereal grinder, paddy huller, oil expeller, saw mill, as well as to produce electricity when coupled with an electric generator (GORKHALI 2010).

Tide Mills

Tide mills are made with a water wheel that is either placed across a tidal inlet or a section of an estuary made into a reservoir. Rising tides enter the mill pond through a one-way gate that closes automatically when the tide begins to fall. The stored water can then be used to turn a water wheel.

River Turbines

River turbines are turbines placed in a flowing river or canal, which are tethered to one side, and pump water to the shore. Output depends on river speed and depth.

Hydraulic Ram Pumps

Also known as “hydrams”, hydraulic rams are automatic pumping devices that use a large flow of falling water through a small head (low elevation) at an inlet in order to lift a small flow of water through a much higher head (high elevation) at an outlet, thus lifting the water (PRACTICAL ACTION 2002).

Applications of Mechanical Water Use

The dominant uses of mechanical power include water supply, agriculture, agro-processing, natural resource extraction, small-scale manufacturing, and lifting and crossing.

Water Supply

Having a clean and reliable source of drinking water is essential in improving the health of a community. In rural areas, water collection is often the responsibility of women, and consumes a great deal of time and energy. Mechanised water pumps can reduce the time and physical strain of water collection for women, allowing them to focus more on other activities, such as caring for children or taking care of their own health.

| Service | Typical technology | Mechanical power alternative |

| Drinking, irrigation, livestock watering | Container (bucket) for lifting / carrying water | Hydraulic ram, water wheel, river turbine |

Applicability of mechanical power at point of use. Source: BATES et al. (2009)

Agro-Processing

Post-harvest activity can be critical in helping farmers increase their income. For activities like milling, pressing, cutting, and shredding, Improved water mills can have an 80–90% increase in power use and efficiency compared to a traditional water mill. They can also have multiple uses such as for both agro-processing and power generation, which can increase the load of the mill and make such installations more sustainable.

| Service | Typical technology | Mechanical power alternatives |

| Milling, pressing | Hand ground, flail | Water mill |

| Cutting, shredding | Knife | Water-powered saw mills |

Applicability of mechanical power at point of use. Source: BATES et al. (2009)

Natural Resource Extraction

Artisanal and small-scale mining may be the only livelihood opportunity for some people, or may be their source of income during the agricultural off-season. There are many technologies that can reduce the effort needed for mining mentioned below.

| Service | Typical technology | Mechanical power alternative | |

| Minerals | Washing | Hand washed | Water powered water jet |

| Grading | Hand screen | Water powered shaker | |

| Timber | Sawing | Hand saw | Powered saw (sawmill, chainsaw) |

Applicability of mechanical power at point of use. Source: BATES et al. (2009)

Small-Scale Manufacturing

Mechanical power technologies allow micro-enterprises to produce goods consistently at the same quality and at a faster production rate. This, in turn, will directly affect their income for the same time spent on labour.

| Services | Typical technology | Mechanical power alternative |

| Wood working, carpentry | Hand saw | Saw mill |

Applicability of mechanical power at point of use. Source: BATES et al. (2009)

Lifting

Water can also be used for transport purposes. In countries such as Switzerland and France, water has historically been used for powering cable cars, using natural gradients and counter weights to drive cars up and down hills. These technologies are still in use today, but many have been replaced with designs that are powered by engines (DE DECKER 2009).

How to Optimise?

Mechanical water use is a non-consumptive water use. Therefore, there are possibilities to link mechanical water use to other uses, such as irrigation in agriculture. This can reduce the investment costs for individual users, thus expanding the possibilities for income generation and development.

Water for Energy and the Millennium Development Goals

Mechanical uses of water have many positive development impacts, which can be regarded for each of the Millennium Development Goals:

| Goal | Impact |

| Goal 1: Eradication extreme poverty and hunger |

|

| Goal 2: Achieve universal primary education |

|

| Goal 3: Promote gender equality and empower women |

|

| Goal 4: Reduce child mortality |

|

| Goal 5: Improve maternal health |

|

| Goal 6: Combat HIV/AIDS, malaria, and other diseases |

|

| Goal 7: Ensure environmental sustainability |

|

| Goal 8: Develop a Global Partnership for Development |

|

For more information on the Millennium Development Goals with regard to water and sanitation, see Access to Water and Sanitation, and Water Sanitation and Development.

Cost

- Because of the large increases in working productivity and efficiency, mechanical water use is considered to be one of the most cost-effective ways of supporting poor people.

- Mechanical devices are generally low-investment. However, the upfront capital needed is a key barrier in rural areas where investment capital is scarce. Microfinance institutions have been successful in overcoming this barrier.

- When investment capital is available, mechanical water use can nearly double revenue due to increased productivity.

- When multiple users are involved (for example when coupling mechanical water use with irrigation), investment costs are decreased for all users, and there may be greater opportunities for income generation.

Mechanical water use relies on flowing water. Technologies can be implemented wherever there is enough force by moving water to drive the device. This force is dependent on the quantity of water, as well as the velocity (speed) at which it is flowing. Therefore, mechanical water use is most applicable where there is a steady source of flowing water (i.e. rivers, streams) to drive the machinery.

Expanding Energy Access in Developing Countries: The Role of Mechanical Power

Water powered cable trains

Improving Livelihood of Rural Mountain People through Promotion of Pico-Hydro Technologies. A Case of Nepal

The History of the Noria

Hydraulic Ram Pumps

A hydraulic ram pump is an automatic pumping device, which utilises a small fall of water to lift a fraction of the supply flow to a much greater height. This technical brief elaborates on the principle, installation requirements, and the design and performance characteristics of this pump system.

PRACTICAL ACTION (2002): Hydraulic Ram Pumps. Bourton on Dunsmore: Practical Action URL [Accessed: 04.10.2012] PDFOpening Productive Avenues for Rural Women through Improved Water Mills in Nepal

This short case study focus on the technical aspects and overall performance improved water mills in Nepal. These improved water mills have brought an increase in grinding capacity as well as direct benefits to woman (involved in new economic activities).

SHRESTHA, L.K. ; SHRESTHA G.R. (2006): Opening Productive Avenues for Rural Women through Improved Water Mills in Nepal. In: Energia News : Volume 9 , 8-10. URL [Accessed: 09.05.2019]Working with Watermills

Universal access to modern energy for the poor

Historical Transformations of Water Management

This document provides a detailed account of the history of water management. It covers diverse topics related to the history of technological innovations in water management from irrigation to industrial water use, as well as changing attitudes, policies, and ethical considerations regarding water use throughout history.

HASSAN, F. (2011): Historical Transformations of Water Management . A Punctuated, Co-evolutionary Theory. (= Water History for our Times , 2 ). Paris: United Nations Educational, Scientific and Cultural Organization (UNESCO) URL [Accessed: 28.03.2012]How to Develop a Micro Hydro Scheme

This guide provides a concise technical guide to build a micro hydro system, with sufficient technological knowledge. Aspects such as capacity, equipment and permissions are discussed in this document. This report provides a special section on water wheels.

HILL, P. (2009): How to Develop a Micro Hydro Scheme. West Yorks, U.K.: Alternative Technology Centre URL [Accessed: 09.05.2019]Financing Watermill Upgrades, The Business Case for Banking Support

This summary report presents the business case for supporting the upgrading of traditional watermills with improved technology. The report is directed at the banking community with the aim of encouraging rural and agricultural banks to offer appropriate finance for new projects. The report provides an overview of the technical, financial, social and market characteristics of watermill upgrades.

IT POWER (2011): Financing Watermill Upgrades, The Business Case for Banking Support. London: United Kingdom Department for International Development (DFID). [Accessed: 28.03.2012] PDFWater Power in Dry Continent: The Transfer of Watermill Technology from Britain to Australia in the Nineteenth Century

This report presents the results of a study aiming to construct a model for the transfer and adaptation of watermills from Britain to Australia in the nineteenth century. It provides a model and a number of factors to consider when a country decides to import a technology from another country.

PEARSON, W. (1996): Water Power in Dry Continent: The Transfer of Watermill Technology from Britain to Australia in the Nineteenth Century. In: Australasian Historical Archaeology: Volume 14 , 46-62. URL [Accessed: 09.05.2019]Water Power Sawmills in New Foundland

This book is a historical account of the use of waterwheels in Newfoundland, Canada. It provides descriptions as well as technical drawings of the many types of waterwheels that were used in this region.

ROBERTSON, A. (2005): Water Power Sawmills in New Foundland. St John’s: Alexander Robertson URL [Accessed: 09.05.2019]Noria. In the End of Famine in Africa

In Medinet El Faiyum, Egypt, the installation of a noria has been successful in increasing food security despite the lack of rainfall in the region. Farmers are able to harvest three times a year despite the fact that the region receives only three days of rain a year. This is thanks to waterwheels that were introduced several centuries ago by Ptolemic engineers. They are still working today side by side with electric water pumps to grow olives, vegetables, fruits, nuts, sugar cane, rice, and wheat.

KITIO, V. (2011): Noria. In the End of Famine in Africa. Mbouda, Cameroon: African Centre for Renewable Energy & Sustainable Technology URL [Accessed: 28.03.2012]Opening Productive Avenues for Rural Women through Improved Water Mills in Nepal

This short case study focus on the technical aspects and overall performance improved water mills in Nepal. These improved water mills have brought an increase in grinding capacity as well as direct benefits to woman (involved in new economic activities).

SHRESTHA, L.K. ; SHRESTHA G.R. (2006): Opening Productive Avenues for Rural Women through Improved Water Mills in Nepal. In: Energia News : Volume 9 , 8-10. URL [Accessed: 09.05.2019]Rediscovering the Waterwheel “Noria Al-Muhammadiyya”

This presentation includes an overview about water-driven waterwheels and is illustrated with photos, draws and sketches about the different water devices.

SAMMAN, M. (2005): Rediscovering the Waterwheel “Noria Al-Muhammadiyya”. New York: American Society of Mechanical Engineers URL [Accessed: 09.05.2019]Ashden Awards Case Study

This case study presents a resume of the programme to upgrade traditional water mills in remote villages in Nepal. The technological aspects as well as cost and environmental and social benefits are included in this document.

CENTRE FOR RURAL TECHNOLOGY (2007): Ashden Awards Case Study. Kathmandu, Nepal: Centre for Rural Technology Nepal. [Accessed: 30.03.2012] PDFNoria and Small Scale Irrigation: Changing the Face of Upland Farming

This factsheet provides information on a rural development Lao PDR. Whereas the overall goal of the project is to be a trial for the Noria (water wheel) technology, the project seeks to increase rice production and production efficiency in the target area.

FRANGI, B. (2010): Noria and Small Scale Irrigation: Changing the Face of Upland Farming. Lao PDR: Care International in Lao Peoples Democratic Republic URL [Accessed: 28.03.2012]Water Mill

This paper describes the design and implementation of a multipurpose power unit at existing water mills from Kashmir to Arunachal Pradesh in India. These new multipurpose systems aims to increased milling capacity, oil expelling, rice hulling, spice-hulling, processing of dairy and food products, workshop machines, wood working, metal working, textiles carding, and commercial cooking.

INDIAN INSTITUTE OF TECHNOLOGY (2008): Water Mill. Roorkee, India: Indian Institute of Technology Roorkee Alternate Hydro Energy Centre URL [Accessed: 28.03.2012]Centre for Rural Technology, Nepal, water mills in Himalayas - Ashden Award winner

This video shows the improved water mills project in Nepal, developed by the Centre of Rural Technology. The documentary describes how the project was initiated and all the different actors involved (e.g. manufactures, service centres, farmers) in the improved water mills.

L’histoire d’un voyage hors du commun

This is a website that host information on the Noria project, that aims to meet local people around the world and visit the project on water subjects in order to observe and report the importance for the economy of this vital resource.

Government of Nepal, Ministry of Energy, Water Resources and Irrigation. Alternative Energy Promotion Centre

This is an official website from the government of Nepal with the objective of developing and promoting renewable energy technologies in the country. There is a special section that contains documents, description, and photos on improved water mills.