Executive Summary

Industries require different qualities of water and other flow streams like chemicals, energy, nutrients, etc. These by-products can be traded in order to optimise each industry’s water and energy usage. This approach is often called industrial symbiosis. This term references ecological symbiosis when two or more organisms "live" together for mutual or one-sided benefit. In industrial symbiosis, traditionally separate industries engage in a long-term partnership to increase their competitive capacity by physically exchanging materials, energy, water, and/or by-products.

| In | Out |

|---|---|

Precipitation, Freshwater, Drinking Water, Blackwater, Greywater, Fertigation Water, Treated Water, Energy |

Blackwater, Greywater, Fertigation Water, Treated Water |

Introduction

Reusing products (e.g. water) within different industries is often called industrial symbiosis. Industrial symbiosis is part of a new field called industrial ecology. Industrial ecology is principally concerned with the flow of materials and energy through systems at different scales, from products to factories and up to national and global levels. The keys to industrial symbiosis are collaboration (matching needs and openness) and the synergistic possibilities offered by geographic proximity. The three major opportunities for industrial symbiosis are:

- Exchanging by-products,

- Sharing management of utilities, and

- Sharing ancillary services.

This factsheet will cover opportunities in by-product reuse to optimise water use. Typical examples are the symbiosis of an industry producing heat and nitrogen rich wastewater with fish aquaculture or plant aquaculture.

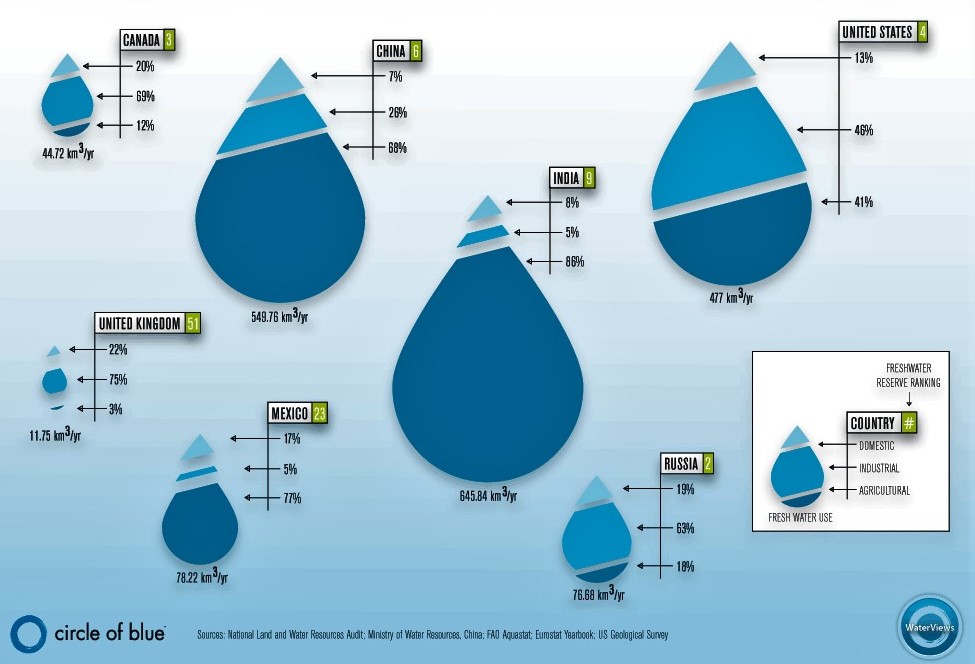

Industry is the fourth largest consumer of water in the world (UNESCO 2009). Industry withdraws 5-10% of global water, ranging from 50% of national withdrawals for developed countries to 5% for developing nations (UNESCO 2009). The primary industrial uses of water are for energy (hydropower), cooling water (from power generation), process water (chemical processes, steam for direct drive power), products and waste disposal (washing) (WBCSD 2009). Industrial symbiosis has the potential to create closed loop processes that drastically alter the industrial process paradigm from extraction to renewal.

Industrial symbiosis can result in considerable environmental and economic benefits for participants, however recent studies in Yale's Journal of Industrial Ecology have found that the majority of benefits occur upstream and not at the plants themselves. Paper and pulp mills operating as industrial ‘symbionts’ had modest improvements in environmental impacts of 5-20% (SOKKA et al. 2010).

Water and By-Product Reuse

By-product reuse requires information sharing between firms about what each has to offer in order for firms to self organise. Firms also need assurance about the quality and consistency of the by-product. Biogas settlers may benefit from nutrient rich wastewater from another firm, while a plant or fish aquaculture might need to be promised that the water never contains certain toxins or organisms. By-product sharing must answer to the same concerns as traditional purchasing relationships: supply security, quality control and availability.

Examples of By-Products and their Reuse Opportunities

- Fly ash from power plants for concrete manufacturing

- Organic waste from fermentation, brewery or pharmaceuticals for fertiliser manufacturing (see also use of compost)

- Steam from power plants can be reused by oil refineries

- Treated greywater and other wastewater can be reused in cooling towers for power plant

Examples of Water Reuse Opportunities

With appropriate controls, industrial water can be reused for many industrial processes, including the following:

- Material washing

- Process rinse water

- Crate and pallet washing

- Hardstand and vehicle washing

- Industrial fire protection

- In production line

- pH adjustment

Non-Industrial Water Reuse Opportunities

With appropriate controls, and where risks can be managed to an acceptable level, industrial water may potentially be reused for the following uses:

- Crop and landscape irrigation, including irrigation of municipal parks and gardens (e.g. surface and subsurface drip irrigation)

- Construction (for example, road compaction)

- Dust suppression

- Fire protection

- Toilet flushing at non-residential facilities

- Heating/cooling (air-conditioning) systems

- Commercial car washing facilities or depots

- Commercial laundries or washing machines at non-residential facilities.

Wastewater Treatment Can Increase Reuse

To increase opportunities for reuse between firms treatment systems may be necessary. Collective management of wastewater treatment plants can lower costs for all participants.

Possible Treatments

Possible treatment options for water reuse include: waste stabilisation ponds, aerated ponds, trickling filters, vertical flow constructed wetland, hybrid constructed wetland, freesurface constructed wetland and horizontal flow constructed wetland.

Treatment options where biogas can be produced using anaerobic digestion: UASB reactors, biogas settlers or in large scale digesters.

Advanced (more high-tech options): activated sludge, MBRs, advanced oxidation processes, ozonation, activated carbon.

Share in Management of Utilities

Another form of industrial symbiosis can be simple utility sharing. For example, several firms could share a closed-loop solvent recovery programme collectively run or in cooperation with a local wastewater treatment service. Each firm may not use enough solvents to justify a system of solvent recovery, but several firms together can. Pulling solvents out of the waste stream reduces the wastewater treatment necessary and creates the potential for reuse (ASHTON 2008).

Share Ancillary Services

Geographically close firms can save money and energy by sharing ancillary services like transportation, landscaping, waste collection, and emergency management. For example, companies could share reservoirs for storing water for industrial fire protection (ASHTON 2008). Examples:

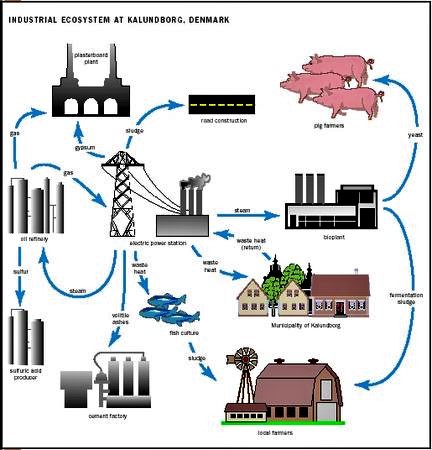

- The term industrial symbiosis was popularised in the small town of Kalundborg, Denmark to describe their unique partnership for sharing groundwater, surface water, wastewater, steam, sludge, gas, sulphur, fuel, etc. between several different industries.

Another example of industrial symbiosis is located in Switzerland. The Wolhusen Tropenhaus represents long-term cooperation between private and public enterprise. Waste heat from a nearby natural gas plant is run through a steam generator to produce energy for the greenhouse nearby. The waste heat from that process is used to heat a nearby hospital and to heat water for the greenhouse's aquaculture system. Currently the hospital and greenhouse use 40% of the natural gas plants waste heat.

Primarily, case studies of industrial symbiosis have come from regions with large-scale heavy industrial processes like Kwinana industrial area in Australia or Rotterdam harbour in the Netherlands (ASHTON 2008). However, small-scale agricultural businesses have also engaged in industrial symbiosis, like Montfort Boys Town in Fiji (ASHTON 2008). Many also exist that are not documented or advertised as such.

Reusing water between industries is most applicable to industries that depend on water within close geographic proximity to each other. A high level of trust must be established in order for firms to work together. The sharing of open source information about the location and quantities of by-products generated has shown to dramatically increase the likelihood of industrial symbiotic relationships forming (DOYLE & PEARCE 2009).

Understanding the Organization of Industrial Ecosystems: A Social Network Approach

Fresh Water Reserves and Water Use by Sector

Utilization of Virtual Globes for Open Source Industrial Symbiosis

Industrial Symbiosis

Analyzing the Environmental Benefits of Industrial Symbiosis

Chapter 7: Evolution of Water Use

Water Facts and Trends

This presentation contains some essential graphs and information on the water cycle as such. It is based on the 2009 WBCSD publication “Water Facts and Trends” (see further above).

WBCSD (2009): Water Facts and Trends. (PPT Presentation). Geneva: World Business Council for Sustainable Development URL [Accessed: 20.04.2010]Industrial Ecology - Industrial Ecosystem at Kalundborg, Denmark

Industrial Symbiosis in Puerto Rico: Environmentally Related Agglomeration Economies

This paper conceptualises the relationship between agglomeration economies and industrial symbiosis, finding that many negative environmental externalities can be reduced while increasing production efficiency. Four industrial regions of Puerto Rico, all with agglomeration economies, but only two with significant industrial symbiosis, highlight the contribution of symbiosis and how it can influence both static and dynamic agglomeration economies.

ASHTON, W. S. (2008): Industrial Symbiosis in Puerto Rico: Environmentally Related Agglomeration Economies. New Haven, CT: School of Forestry & Environmental Studies, Yale University URL [Accessed: 02.01.2012]Planning and Uncovering Industrial Symbiosis. Comparing the Rotterdam and Oestergoetland regions

Academic discussion of the planned industrial symbiosis activities in Rotterdam Harbor around waste heat reuse and the unplanned industrial symbiosis and biogas activities in the forest industry of Oestergoetland, Sweden.

BAAS, L. (2011): Planning and Uncovering Industrial Symbiosis. Comparing the Rotterdam and Oestergoetland regions. In: Business Strategy & Environment, Special issue Industrial Ecology: Volume 20 , 428-440. URL [Accessed: 06.05.2019]Industrial Symbiosis in the Australian Minerals Industry

An academic review of industrial water reuse between mining industries in Australia. Barriers and triggers to cooperation are discussed.

BEERS, D. van ; CORDER, G. ; BOSSILKOV, A. ; BERKEL, R. van (2007): Industrial Symbiosis in the Australian Minerals Industry. In: Journal of Industrial Ecology : Volume 11 , 55-72. URL [Accessed: 06.05.2019]The Hannover Principles. Design for Sustainability

The Hannover Principles provide nine principles to create sustainable businesses for a healthier planet. The principles are simple and inspiring and can be incorporated into training materials within firms.

MCDONOUGH, W. (2000): The Hannover Principles. Design for Sustainability. Charlottesville, VA: William McDonough Architects URL [Accessed: 15.05.2014]Water for Business. Initiatives guiding sustainable water management in the private sector

The future of any business depends on the sustainability of water resources, which are increasingly under pressure. At the same time, consumer awareness and investors' increased scrutiny of corporate water risks have resulted in stronger expectations that companies should reveal their ‘water performance'. To respond effectively, the business community needs guidance, tools, standards and schemes to enable change to more sustainable practices. This is what this publication aims at providing.

WBCSD (2009): Water for Business. Initiatives guiding sustainable water management in the private sector. Geneva: WBDSC and IUCN URL [Accessed: 06.05.2019]Business in the world of water: WBCSD Water Scenarios to 2025

The H2O scenarios offer three stories about the role of business in relation to the growing issue of water in the world. These stories do not try to cover everything but attempt to bring to life a limited number of alternative future environments that will challenge our economic viability, social legitimacy, and global fitness in the marketplace.

WBCSD (2009): Business in the world of water: WBCSD Water Scenarios to 2025. Geneva: WBCSD URL [Accessed: 06.05.2019]International Society for Industrial Ecology

International Society for Industrial Ecology, a research institute based out of Yale University in Connecticut, USA.

Progress in Industrial Ecology, An International Journal

Progress in Industrial Ecology is an international journal started in 2004 published by InderScience Publishers.

Kalundborg Symbiose

This website for Kalundborg’s Centre for Industrial Symbiosis has a host of information on their projects, organisation and strategies. They describe what they think are the fundamental criteria for reuse between businesses.