Executive Summary

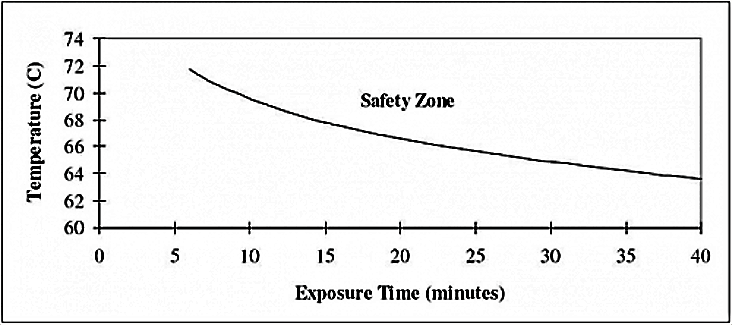

Contrary to belief, it is not necessary to boil certain water to make it safe to drink. Heating water to 65°C (149°F) for 6 minutes, or to a higher temperature for a shorter time, will kill all germs, viruses, and parasites. This process is called pasteurisation (ANDREATTA 2007). Solar pasteurisation has proven to be a very low-cost disinfection method to produce drinking water out of non-turbid fresh water. However, solar pasteurisation is not that easy to implement and monitor, thus it is not a wide spread method for point-of-use water treatment.

| In | Out |

|---|---|

Drinking Water |

Introduction

Simple techniques for treating water at home and storing it in safe containers (see HWTS) could contribute to the MDGs (see access to water and sanitation). Pasteurisation is one of many techniques to disinfect drinking water and is applicable to developing countries. Other techniques such as chlorination, ozonation or operation of wells may be more suitable particularly if a large amount of water is needed. Conversely, if a relatively small amount of water is needed, pasteurisation systems, like other HWTS methods have the advantage of being able to be scaled down with a corresponding decrease in cost. In other words, if only little money is available, you can use pasteurisation to get a little clean water, perhaps enough for a family, but not a village (ANDREATTA 2007).

Together with boiling, the WHO Guidelines for Drinking Water call pasteurisation a thermal heat technology, but do not directly recommend pasteurisation to be applied for producing drinking water (WHO 2011).

Alternatively to boiling, solar energy might have a role to play in improving water quality in those regions that enjoy a hot, sunny climate (JOYCE et al. 1996). Today, the solar disinfection (SODIS) technique seems the most widely applied when it comes to using solar energy for water disinfection. SODIS focuses on a combination of the antibacterial role of solar UV radiation and elevated temperature, while solar pasteurisation is making use of the thermal solar energy only (SAFAPOUR & METCALF 1999).

Today, throughout the world, beverages such as milk, fruit juice, beer and wine are disinfected through pasteurisation on an industrial scale. Consumers are familiar with and trust the process of pasteurisation. Apart from water, milk can also be pasteurised at home, a procedure used to make it more durable. In case of milk, pasteurisation is reached when heated above 63 °C for 30 minutes (WHO 2011).

What is solar pasteurisation?

(Adapted from CAWST 2009)

Pasteurisation is the process of disinfecting water by heat or radiation without boiling. Typical water pasteurisation achieves the same effect as boiling, but at a lower temperature (usually 65-75°C/ 149-167°F), over a longer period of time. A simple method of pasteurising water is to put blackened containers with water in a solar cooker. The solar cooker reflects sunlight onto the container, which heats up the content. The cooker may be an insulated box made of wood, cardboard, plastic, or woven straw, with reflective panels to concentrate sunlight onto the water container. It may also be an arrangement of reflective panels, or a reflective “satellite dish”, on which the water pot sits. The box cooker should be frequently repositioned to ensure it is catching all available sunlight (and never in shade). A thermometer or indicator is needed to tell when the required temperature is reached for pasteurisation to monitor the required exposure time of six minutes (ANDREATTA 2007). Common devices for monitoring the water temperature use either beeswax, which melts at 62°C (143.6°F), or soybean fat, which melts at 69°C (156.2°F). A simple device known as the Water Pasteurisation Indicator (WAPI) has been developed at the University of California. Water may take one to four hours or more to heat to those temperatures.

Heating the water to the pasteurisation temperature rather than the boiling point reduces the energy required by at least 50% (ANDREATTA 2007). However, solar pasteurisation is only effective if treated water is protected from post-treatment contamination during storage (WHO 2011).

How does it remove contamination?

(Adapted from CLASEN et al. 2007)

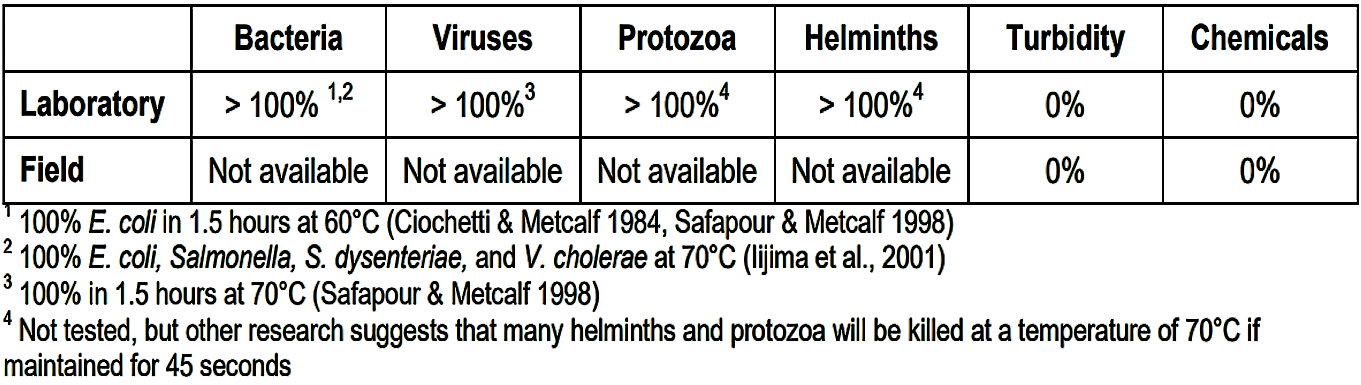

Boiling or heating with fuel is perhaps the oldest means of disinfecting water at the household level and is also one of the most effective. It kills or deactivates all classes of waterborne pathogens, including protozoan cysts that have shown resistance to chemical disinfection and viruses that are too small to be mechanically removed by microfiltration. As the water heats due to radiation from the sun, the increased temperature will kill or inactivate an important part of commonly waterborne pathogenic bacteria, viruses, helminths, and protozoa at a temperature between 65° and 75°C (149-167°F) (CAWST 2009). But, spores are more resistant to thermal inactivation than vegetative cells; treatment to reduce spores requires a thermal treatment up to boiling point and must ensure sufficient temperature and time (WHO 2011). Furthermore, solar pasteurisation does not improve turbidity, odour, taste, colour or chemical contamination.

As temperatures reach 50°C or greater, pathogenic microbes are inactivated. The temperatures which cause approximately a 1-log decrease in viability within 1 min are 55°C for protozoan cysts; 60°C for E. coli, enteric bacteria, and rotavirus; and 65°C for hepatitis A virus (3, 5, 7–9, 16). When the WAPI wax melts at about 70°C, the cumulative lethal effect is determined by the gradual increase in temperature, often at least 30 min from 50 to 70°C, as well as the gradual cooling once the water is removed. In addition, the water at the bottom of the black jar is often 5 to 10°C cooler than the water at the top of the jar. Microbes in the upper portion will have been inactivated before those in the bottom portion, where the WAPI is located (SAFAPOUR & METCALF 1999).

Pasteurisation time decreases exponentially with increasing temperature. Above 50°C, time decreases at roughly a factor of 10 for every 10°C increase in pasteurisation temperature. Viruses appear the hardest to kill and essentially set the boundary for acceptable time-temperature processes (BURCH & THOMAS 1998). In rural Kenya, a simple thermo indicator which changes colour at 70°C was applied to show household members when pasteurisation temperature had been reached. This increased the number of households whose drinking water was free of coliforms from 10.7 to 43.1% and significantly reduced the incidence of severe diarrhoea compared to a control group (IIJIMA et al. 2001).

Different solar pasteurisation devices

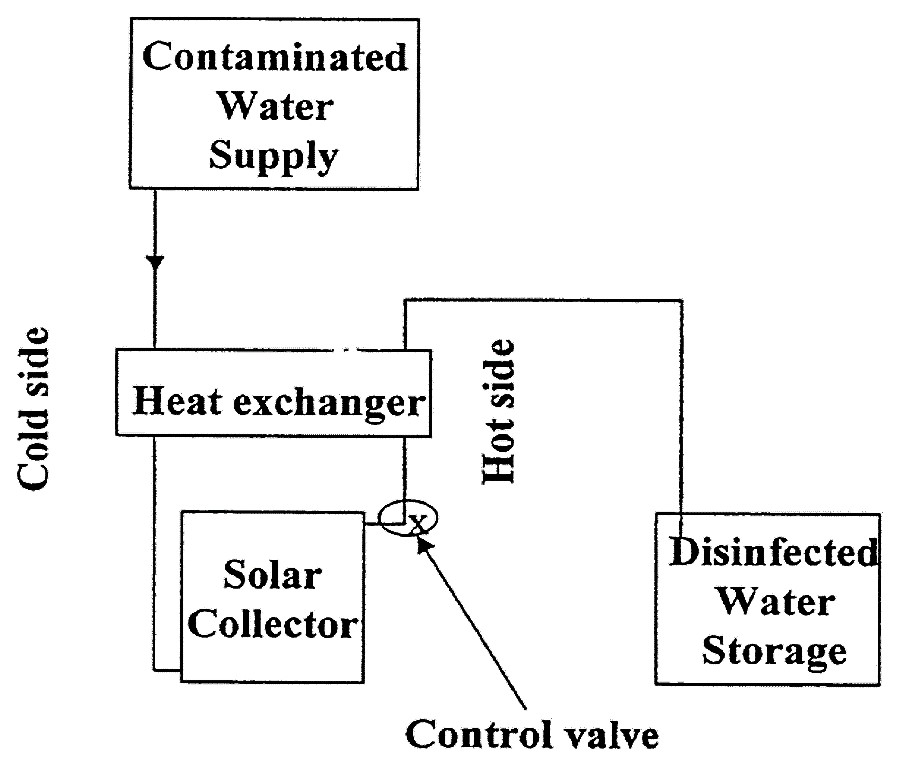

Literature distinguishes between batch devices and flow-through solar devices. Batch devices are used to heat water on a home scale with a simple solar cooker. While potentially inexpensive, durability of the solar box needs further investigation. Compared to other energy sources it can save fuel costs, but not labour costs, which are still relatively high (BURCH & THOMAS 1998). A portable version is the AquaPac, a low cost polyethylene plastic with UV inhibitors added, and air-filled bubble pack sheeting (NWP 2010). An example for an enhanced batch device is the solar puddle, which essentially is a puddle in a greenhouse. A combination of (black) plastic sheeting is put in a shallow pit and then filled with water to be pasteurised by the solar heat. On days with good sunshine the required temperature with a water depth of up to 62 mm (2 1/2 inches) can be reached (ANDREATTA 2009). Another way to pasteurise water is to use flow-through pasteurisation devices. They can be enhanced with a heat exchanger by recycling heat from the outgoing pasteurised water.

Flow-through devices have several advantages over the simpler batch processes. First, potable water becomes available throughout the day as new increments of treated water are added to the clean storage vessel. Second, this type of unit can adapt to variable solar conditions and is an automatic process, also decreasing the likelihood of an accident occurring when transferring water in and out of a batch unit e.g. a solar cooker jar (ANDREATTA 2007). Flow-through devices can make use of wasted heat like the one generated in traditional clay ovens, so called “chullis” (ISLAM & JOHNSTON 2006). The main drawback of flow-through solar pasteurisation devices is the difficulty of ensuring safe storage, as the water needs to be transferred to a new recipient before consumption.

The Solar Pasteuriser with Integral Heat Exchanger (SPIHX) collects and converts solar energy to heat energy to bring water to pasteurisation levels. Once pasteurised, the thermostat valve opens and the water flows through the bottom channel. The middle aluminium sheet facilitates heat exchange between the hot outgoing pasteurised water and cold incoming contaminated water (RIT 2007).

The solar pasteurisation method is effective to remove bacteria, viruses, protozoa and helminths from raw fresh water. It cannot produce drinking water from raw water with high turbidity and dissolved matter. While the removal capacity has predominantly been proved in laboratory tests, the solar pasteurisation method seems more suitable on household level rather than for producing high quantities of drinking water. Because it relies on solar energy its effectiveness depends on the daily hours of sunshine in the area of application.

Solar pasteurisation might be an option on both, the village and household level. But household usage is more competitive because village-scale alternatives have much lower treatment cost. Existing solar devices have water disinfection costs that are an order of magnitude less than boiling. Solar thermal pasteurisation with existing manufactured devices costs more than the remaining alternatives but is highly effective and lowest in maintenance (BURCH & THOMAS 1998).

Quite some solar pasteurisers that have been developed are an educational tool or curiosity rather than practical methods of producing safe water applicable in developing countries on a large scale.

A Summary of Water Pasteurization Techniques

An Overview of Water Disinfection in Developing Countries and the Potential for Solar Thermal Water Pasteurization

This document gives a short introduction to the pasteurisation technique in general, and compares it with other water disinfection methods. Pasteurisation is presented in a batch process and as a flow-through solar thermal device.

BURCH, J.D. ; THOMAS, K.E. (1998): An Overview of Water Disinfection in Developing Countries and the Potential for Solar Thermal Water Pasteurization. In: Solar Energy: Volume 64 , 1-3. URL [Accessed: 04.09.2011]HWTS Factsheet: Solar Pasteurization

A 3-page factsheet on solar pasteurisation, focussing on treatment efficiency, operating criteria and other information on solar pasteurisation.

CAWST (2009): HWTS Factsheet: Solar Pasteurization. Calgary: Centre for Affordable Water and Sanitation Technology URL [Accessed: 24.05.2019]Pasteurization of Naturally Contaminated Water with Solar Energy

This short but comprehensive document gives an overview of the development of solar pasteurisation methods and devices and further investigates the feasibility of using solar energy and an SBC to pasteurise contaminated water on sunny or partly cloudy days during the solar season.

CIOCHETTI, D.A. METCALF, R.H. (1984): Pasteurization of Naturally Contaminated Water with Solar Energy. Sacramento: California State University URL [Accessed: 03.09.2011]Microbiological Effectiveness and Cost of Boiling to Disinfect Drinking Water In Rural Vietnam

This paper tries to assess improvement of microbiological quality in drinking water by boiling and cost analysis of boiling in Boc Bo commune in Vietnam.

CLASEN, T.F. ; THAO, D.H. ; BOISSON, S. ; SHIPIN, O. (2007): Microbiological Effectiveness and Cost of Boiling to Disinfect Drinking Water In Rural Vietnam. In: Environmental Science and Technology: Volume 42 , 4255-4260. PDFMicrobiological Effectiveness and Cost of Disinfecting Water by Boiling in Semi-urban India

This paper tries to assess improvement of microbiological quality in drinking water by boiling and cost analysis of boiling in Virar, Vasai and Nalasopara, three sprawling semi-urban communities in India.

CLASEN, T. MCLAUGHLIN, C. NAYAAR, N. BOISSON, S. GUPTA, R. DESAI, D. SHAH, N. (2008): Microbiological Effectiveness and Cost of Disinfecting Water by Boiling in Semi-urban India. Deerfield: The American Society of Tropical Medicine and Hygiene (ASRMH) URL [Accessed: 20.05.2019]Prevention of Bacterial Diarrhoea by Pasteurization of Drinking Water in Kenya

Household Pasteurization of Drinking-water: The Chulli Water-treatment System

This case study from Bangladesh discusses the possibility of using waste heat from the “chulli” clay oven to pasteurise surface water.

ISLAM, M.F. ; JOHNSTON, R.B. (2006): Household Pasteurization of Drinking-water: The Chulli Water-treatment System. In: Journal of Health, Population, and Nutrition: Volume 24 , 3. URL [Accessed: 04.09.2011]Inactivation of Faecal Bacteria in Drinking Water by Solar Heating

The Microbiology of Solar Water Pasteurization, with Applications in East Africa

Smart Disinfection Solutions

This booklet, part of the Smart Water Solutions series provides a wide range of methods and products for home water treatment in rural areas.

NWP (2010): Smart Disinfection Solutions. Examples of small-scale disinfection products for safe drinking water. (= Smart water solutions ). Amsterdam: KIT Publishers URL [Accessed: 17.05.2019]Safety Zone Curve

Enhancement of Solar Water Pasteurization with Reflectors

Guidelines for Drinking-water Quality, Fourth Edition

This volume of the Guidelines for Drinking-water Quality explains requirements to ensure drinking-water safety, including minimum procedures and specific guideline values, and how those requirements are intended to be used. The volume also describes the approaches used in deriving the guidelines, including guideline values. It includes fact sheets on significant microbial and chemical hazards.

WHO (EDITOR) (2011): Guidelines for Drinking-water Quality, Fourth Edition. Geneva: World Health Organization (WHO) URL [Accessed: 11.07.2018]An Overview of Water Disinfection in Developing Countries and the Potential for Solar Thermal Water Pasteurization

This document gives a short introduction to the pasteurisation technique in general, and compares it with other water disinfection methods. Pasteurisation is presented in a batch process and as a flow-through solar thermal device.

BURCH, J.D. ; THOMAS, K.E. (1998): An Overview of Water Disinfection in Developing Countries and the Potential for Solar Thermal Water Pasteurization. In: Solar Energy: Volume 64 , 1-3. URL [Accessed: 04.09.2011]HWTS Factsheet: Solar Pasteurization

A 3-page factsheet on solar pasteurisation, focussing on treatment efficiency, operating criteria and other information on solar pasteurisation.

CAWST (2009): HWTS Factsheet: Solar Pasteurization. Calgary: Centre for Affordable Water and Sanitation Technology URL [Accessed: 24.05.2019]Pasteurization of Naturally Contaminated Water with Solar Energy

This short but comprehensive document gives an overview of the development of solar pasteurisation methods and devices and further investigates the feasibility of using solar energy and an SBC to pasteurise contaminated water on sunny or partly cloudy days during the solar season.

CIOCHETTI, D.A. METCALF, R.H. (1984): Pasteurization of Naturally Contaminated Water with Solar Energy. Sacramento: California State University URL [Accessed: 03.09.2011]Smart Disinfection Solutions

This booklet, part of the Smart Water Solutions series provides a wide range of methods and products for home water treatment in rural areas.

NWP (2010): Smart Disinfection Solutions. Examples of small-scale disinfection products for safe drinking water. (= Smart water solutions ). Amsterdam: KIT Publishers URL [Accessed: 17.05.2019]Conservation et Traitement de l Eau a Domicile

This practical guide provides a review of different processing techniques and adequate water conservation at home and is structured around 10 key questions that should be posed before choosing a suitable solution.

DESILLE, D. (2013): Conservation et Traitement de l Eau a Domicile. Paris: Programme Solidarite Eau (PSeau) URL [Accessed: 06.06.2013]Microbiological Effectiveness and Cost of Boiling to Disinfect Drinking Water In Rural Vietnam

This paper tries to assess improvement of microbiological quality in drinking water by boiling and cost analysis of boiling in Boc Bo commune in Vietnam.

CLASEN, T.F. ; THAO, D.H. ; BOISSON, S. ; SHIPIN, O. (2007): Microbiological Effectiveness and Cost of Boiling to Disinfect Drinking Water In Rural Vietnam. In: Environmental Science and Technology: Volume 42 , 4255-4260. PDFMicrobiological Effectiveness and Cost of Disinfecting Water by Boiling in Semi-urban India

This paper tries to assess improvement of microbiological quality in drinking water by boiling and cost analysis of boiling in Virar, Vasai and Nalasopara, three sprawling semi-urban communities in India.

CLASEN, T. MCLAUGHLIN, C. NAYAAR, N. BOISSON, S. GUPTA, R. DESAI, D. SHAH, N. (2008): Microbiological Effectiveness and Cost of Disinfecting Water by Boiling in Semi-urban India. Deerfield: The American Society of Tropical Medicine and Hygiene (ASRMH) URL [Accessed: 20.05.2019]Household Pasteurization of Drinking-water: The Chulli Water-treatment System

This case study from Bangladesh discusses the possibility of using waste heat from the “chulli” clay oven to pasteurise surface water.

ISLAM, M.F. ; JOHNSTON, R.B. (2006): Household Pasteurization of Drinking-water: The Chulli Water-treatment System. In: Journal of Health, Population, and Nutrition: Volume 24 , 3. URL [Accessed: 04.09.2011]An Introduction to Household Water Treatment and Safe Storage, A CAWST Training Manual

This training manual describes the need of safe drinking water and sanitation and provides relevant information on HWTS process, technologies. It is good reference material for trainers to conduct training on HWTS.

CAWST (2009): An Introduction to Household Water Treatment and Safe Storage, A CAWST Training Manual. Calgary: Centre for Affordable Water and Sanitation Technology (CAWST) URL [Accessed: 13.05.2019]A Summary of Water Pasteurization Techniques

Amoeba and Water

This children’s book provides information on safe drinking water, ways of water contamination, simple HWTS options presented in attractive illustrations and simple languages so that school children can easily understand them.

ENPHO (2007): Amoeba and Water. Kathmandu and New York: Environment and Public Health Organization (ENPHO) and United Nations Children's Fund (UNICEF) URL [Accessed: 19.05.2019]Solar Cookers International (SCI)

This website provides information on Solar Cookers International (SCI), an organisation that began a two-year pilot project in 2007 to increase water quality awareness and to introduce the safe water packages and portable microbiology laboratory to communities in Western Kenya.

Food Safety and Water Pasteurization

This website contains various resources e.g. audio interviews with Bob Metcalf, a prominent promoter of solar pasteurisation.

Water pasteurization

This site is inspired by Wikipedia and provides information on solar pasteurisation with photos, videos, sketches and further references.