Executive Summary

Mechanical dewatering is normally associated with large wastewater treatment plants and is used to separate sludge (residual sludge from wastewater treatment plants or faecal sludge from on-site sanitation) into a liquid and a solid part. The principal methods are belt filter presses, centrifuges and chamber filter presses. These techniques are usually sophisticated and rarely cost-efficient for smaller systems to be implemented on community level. The process does not treat the sludge, it only separates solid from liquid parts. Both solid and liquid parts still contain pathogens and pollutants.

| In | Out |

|---|---|

Faecal Sludge (from wastewater treatment plants or on-site sanitation systems) |

Blackwater, Organic Solid Waste, Compost/Biosolids |

Introduction

Dewatering removes water from sludge (residual sludge from wastewater treatment plants such as activated sludge systems, or faecal sludge from on-site sanitation such as septic tanks or pit latrines) making it easier to handle and less expensive to transport, to compost (see also small or large scale composting), to incinerate (see also small or large scale incineration) or to dispose of in a landfill. Dewatering can be done either with the help of presses or centrifuges (mechanical dewatering), filtration (e.g. in filter bags) or physical (and biological) processes in drying beds. Mechanical dewatering and filtration often require the use of chemicals (coagulants and flocculants) to enhance the process.

Treatment Process and Basic Design Principles

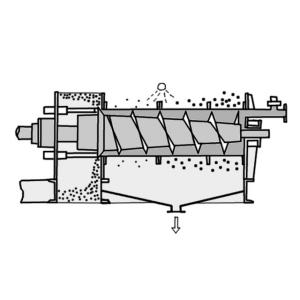

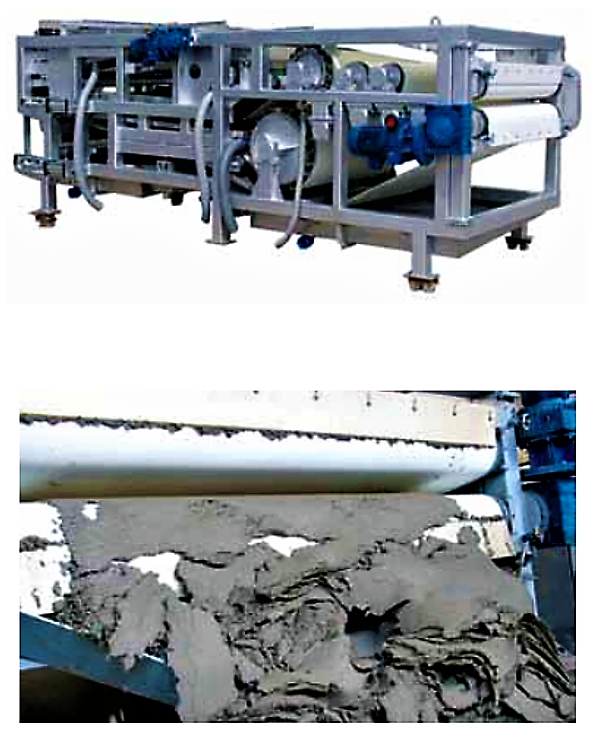

Belt Filter Press

Modern belt presses are based on a combination of chemical conditioning, gravity drainage and mechanical pressure in a continuous feed system to dewater sludge. The sludge is squeezed between tensioned serpentine belts and a series of decreasing diameter rollers (to increase the pressure) to remove moisture and create a dewatered sludge cake (JOHNSONSCREENS 2011).

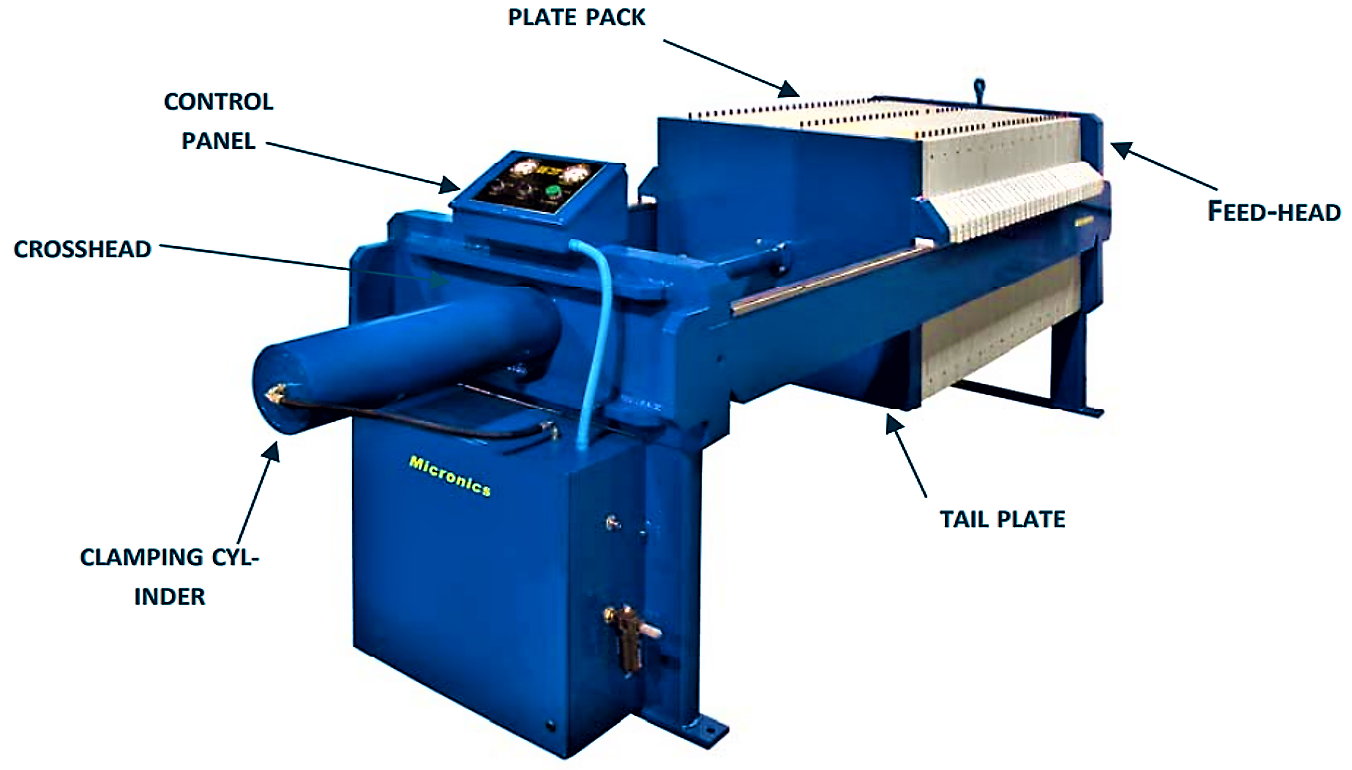

Chamber Filter Press

Chamber filter presses use filters to separate the liquid (filtrate) from the sludge and collect the solids (filter cake) in chambers. A number of such chambers for the collection of the solids are arranged in a plate pack. The filter cloth is supported by the plates of the plate pack. The sludge (optionally mixed with coagulant) is pumped into the chambers and against the filter media. A moving plate (the tail plate) clamps the filter plate pack. The filtrate passes through the filter cloth and exits through the filtrate ports of the filter plate. The filter cake collects on the surface of the filter medium within the chambers until the chamber is full. The cake may be washed or blown dry if necessary. There are manual, semi-automatic and automatic chamber filter presses available.

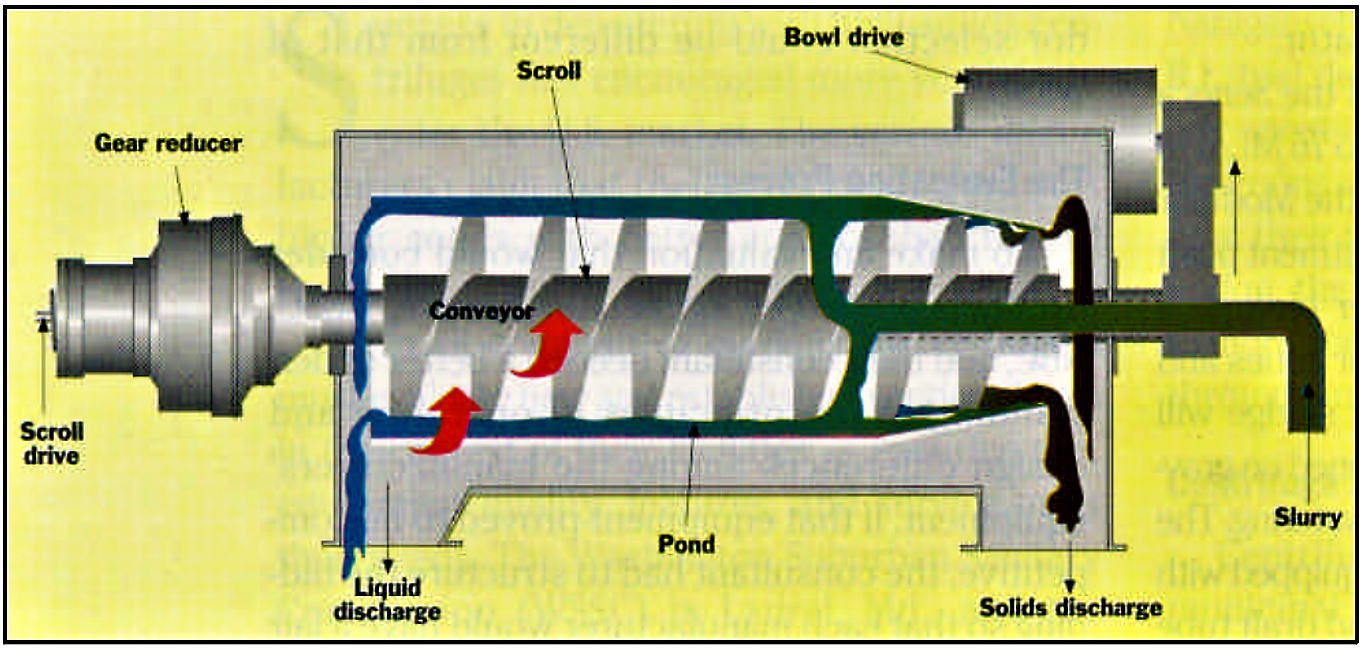

Centrifuge

Adapted from EPA (2000)

Centrifuges operate as continuous feed units, which remove solids by a scroll conveyor and discharge liquid over the weir. The bowl is conical-shaped which helps lift solids out of the liquid allowing them to dry on an inclined surface before being discharged. The picture shows a typical centrifuge thickening and dewatering system.

Cost Considerations

These systems are mostly high-tech and require expert design, which increases costs. As the techniques are usually sophisticated they are rarely cost-efficient for smaller systems to be implemented on community level (HEEB et al. 2008). The most cost effective method of sludge dewatering depends on many factors including plant size, the cost of further processing, end-use (e.g. if the thermal heat can be recovered by incinerating the dried sludge), disposal, odour control requirements, and space limitations (EPA 2000).

Operation and Maintenance

These technical systems require a high degree of operator supervision, and operator training. The mechanical systems such as filters, belts, tensioning systems or bearings have to be maintained correctly to guarantee proper functioning. The performance of primary treatment systems prior to mechanical stage is also a critical determinant of performance. Primary treatment commonly includes the removal of gross solids, and slurry thickening. Routine use of flocculants is essential, normally selected at installation using advice and the results of on-site testing from polymer chemical suppliers (FSA 2002).

The liquid part needs to be treated: it is either circulated back into the wastewater treatment plant from where the sludge comes from (e.g. activated sludge or treated in vertical flow or horizontal flow constructed wetlands). The solid part has to be burnt in a small or large scale incineration plant or discharged in a landfill; it may also be a composted (see also small or large scale composting facility).

Health Aspects

This process does not serve the treatment of wastewater; it only separates solids from liquids. Both solid and liquid parts still contain pathogens and pollutants (HEEB et al. 2008) and have to be treated (see Operation and Maintenance).

At a Glance

| Working Principle | Sludge is separated in a solid and a liquid part with the help of a physical process such as filtration, squeezing, centrifugal separation or compaction. |

| Capacity/Adequacy | Usually applied in large scale and sophisticated wastewater treatment plants. Not used on neighbourhood/ community level. |

| Performance | High |

| Costs | High |

| Self-help Compatibility | Low (rather high-tech). |

| O&M | Mechanical parts need periodical inspection. |

| Reliability | Technique does not work in case of power failure. |

| Main strength | Reduces volume of sludge and saves storage and transport costs. |

| Main weakness | This is an expensive high-tech solution for dewatering sludge. |

Mechanical dewatering is mostly applied for the treatment of residual sludge in large-scale centralised wastewater treatment plants. Dewatering of sludge reduces transport loads and sludge with low moisture content is easier to handle. It is also required prior to landfilling to reduce leachate production, before composting or incineration of dewatered sludge.

Centrifuge Thickening and Dewatering

This document describes the centrifugal thickening and dewatering process. It is a high-speed process that uses the force from rapid rotation of a cylindrical bowl to separate wastewater solids from liquid.

EPA (2000): Centrifuge Thickening and Dewatering. Washington D.C.: United States Environmental Protection Agency (EPA) URL [Accessed: 10.06.2019]Emerging Technologies for Biosolids Management

Case Study 8 – Belt Press

This case study gives information about a belt press system (description, O&M, costs, etc.) and summarises the selection criteria.

FSA (2002): Case Study 8 – Belt Press. In: FSA Environmental: Volume 8 URL [Accessed: 10.06.2019]Ecosan Curriculum 2.3

Belt Press

This flyer describes the most important aspects and provides pictures of the Johnson belt filter press systems.

JOHNSONSCREENS (2011): Belt Press. New Brighton: Johnson Screen Inc. [Accessed: 24.11.2011] PDFFunction of a Filter Press

How does a chamber filter press work? This is described in a few sentences in this flyer.

MICRONICS (n.y): Function of a Filter Press. Portsmouth: Micronics Engineered Filtration URL [Accessed: 24.11.2011]Mechanical Dewatering Using Filter Presses Technology

The filter press is one of the oldest mechanical dewatering devices. Read more about it in this document.

DELTREIL, J.P. (2003): Mechanical Dewatering Using Filter Presses Technology. Limoges: Faure Equipment SA. [Accessed: 24.11.2011] PDFCentrifuge Thickening and Dewatering

This document describes the centrifugal thickening and dewatering process. It is a high-speed process that uses the force from rapid rotation of a cylindrical bowl to separate wastewater solids from liquid.

EPA (2000): Centrifuge Thickening and Dewatering. Washington D.C.: United States Environmental Protection Agency (EPA) URL [Accessed: 10.06.2019]Emerging Technologies for Biosolids Management

Faecal Sludge Management.

This issue presents studies from different regions (Bangladesh, Cameroon, Burkina Faso) that mainly show the non-existence of faecal sludge management. Additionally, the last paper describes a new technological solution (LaDePa) for producing hygienically safe organic fertiliser from sludge from ventilated improved pit toilets (VIPs).

ECOSAN CLUB (2012): Faecal Sludge Management.. (= Sustainable Sanitation Practice , 13 ). Vienna: Ecosan Club URL [Accessed: 16.10.2012]Ecosan Curriculum 2.3

Belt Press

This flyer describes the most important aspects and provides pictures of the Johnson belt filter press systems.

JOHNSONSCREENS (2011): Belt Press. New Brighton: Johnson Screen Inc. [Accessed: 24.11.2011] PDFFunction of a Filter Press

How does a chamber filter press work? This is described in a few sentences in this flyer.

MICRONICS (n.y): Function of a Filter Press. Portsmouth: Micronics Engineered Filtration URL [Accessed: 24.11.2011]Filter Presses

Read more about chamber filter presses and their applications, benefits and options in this paper.

PARKSON (2008): Filter Presses. Manual, Semi-Automatic, Automatic. Fort Lauderdale: Parkson Corporation URL [Accessed: 10.06.2019]A Directory of Environmentally Sound Technologies for the Integrated Management of Solid, Liquid and Hazardous Waste for SIDS in the Caribbean Region

This directory is part of UNEP collaboration with SIDS on the implementation of the Waste Management chapter of the Barbados Programme of Action. It focuses primarily on proven sound environmental technologies for solid, liquid and hazardous waste management plus those currently successfully being used in SIDS within the Caribbean Region.

UNEP (2004): A Directory of Environmentally Sound Technologies for the Integrated Management of Solid, Liquid and Hazardous Waste for SIDS in the Caribbean Region. Nairobi: United Nations Environment Programme Global Programme of Action (UNEP-GPA)) and Caribbean Environmental Health Institute (CEHI) URL [Accessed: 04.08.2023] PDFSludge Treatment Technologies

This document describes several steps of sludge treatment technologies such as sludge stabilisation, dewatering and incineration.

VIGNESWARAN, S. KANDASAMY, J. (n.y): Sludge Treatment Technologies. Paris: UNESCO-EOLSS (Encyclopedia Of Life Support Systems) URL [Accessed: 24.11.2011]Full-Chain Sanitation Services That Last

This paper sets out a framework for the delivery of non-sewered sanitation services that last, are accessible to all and are at scale. The framework is based on IRC International Water and Sanitation’s (IRC) experience and lessons learnt from its engagement in non-sewered sanitation service at scale.

VERHAGEN, J. CARRASCO, M. (2013): Full-Chain Sanitation Services That Last. Non-Sewered Sanitation Services. The Hague: International Water and Sanitation Center (IRC) URL [Accessed: 03.06.2019]Sludge Treatment and Disposal

Sludge Treatment and Disposal is the sixth volume in the series Biological Wastewater Treatment. The book covers in a clear and informative way the sludge characteristics, production, treatment (thickening, dewatering, stabilisation, pathogens removal) and disposal (land application for agricultural purposes, sanitary landfills, landfarming and other methods). Environmental and public health issues are also fully described.

ANDREOLI, C.V. ; SPERLING, M. von ; FERNANDES, F. (2007): Sludge Treatment and Disposal. (= Biological Wastewater Treatment Series , 6 ). London: International Water Association (IWA) Publishing URL [Accessed: 27.05.2019]Case Study 8 – Belt Press

This case study gives information about a belt press system (description, O&M, costs, etc.) and summarises the selection criteria.

FSA (2002): Case Study 8 – Belt Press. In: FSA Environmental: Volume 8 URL [Accessed: 10.06.2019]Impact of Sludge Conditioning on Mechanical Dewatering and Convective Drying

Management of sludge produced within wastewater treatment plants has become a key issue. After thickening, the removal of remaining water using mechanical dewatering and/or thermal drying is essential before any type of valorisation. Polymers are usually employed in the conditioning step in order to promote particle aggregation, making the dewatering easier. In this work the impact of the polymer dosage and nature on dewatering and convective drying of sludge is studied.

BAZZAOUI, R. FRAIKIN, L. GROSLAMBERT, S. SALMON, T. CRINE, M. LEONARD, A. (2011): Impact of Sludge Conditioning on Mechanical Dewatering and Convective Drying. Palma: European Drying Conference – EuroDrying 2011 URL [Accessed: 24.11.2011]Opportunities in Fecal Sludge Management for Cities in Developing Countries: Experiences from the Philippines

In July 2012, a team from RTI International deployed to the Philippines to evaluate four FSM programs with the goal of reporting on best practices and lessons learned. The four cases—Dumaguete City, San Fernando City, Maynilad Water for the west zone of metro Manila, and Manila Water from the east zone of metro Manila—were chosen to highlight their different approaches to implementing FSM.

ROBBINS, D. STRANDE, L. DOCZI, J. (2012): Opportunities in Fecal Sludge Management for Cities in Developing Countries: Experiences from the Philippines. North Carolina: RTI International URL [Accessed: 10.06.2019]Parkson Filter Press

This short clip shows how a Parkson chamber filter press works.