Executive Summary

Pressurised sewers or pressure sewers differ from conventional gravity collection systems, because they use pumps instead of gravity to transport wastewater. The primary effluent is delivered to the collection tank by traditional gravity drainage methods where it is grind before being transported into the pressurised system by pumps. As for central network, no gravity is required; the system can be built with only shallow trenches and relatively small-diameter pipes. It is an effective solution where conventional systems are impractical such as in rocky, hilly or densely populated areas or areas with a high groundwater table.

| In | Out |

|---|---|

Blackwater, Greywater, Brownwater, Urine or Yellowwater, Non-biodegradable Wastewater, Energy |

Blackwater, Greywater, Brownwater, Urine or Yellowwater, Non-biodegradable Wastewater |

Introduction

Sewers are a means of collecting wastewater from multiple sources and delivering the wastewater to an existing collection sewer, and/or to semi-centralised secondary treatment system such as constructed wetlands (free-surface, horizontal or vertical), or waste stabilisation ponds. Conventional sewers transport wastewater and sludge by gravity and therefore require a slope and pumping station. This can lead to high construction cost in hilly or flat terrain. In some cases, a conventional system is almost impossible to construct, e.g. where the groundwater table is high or the topography is extremely flat.

Pressurised sewers (and also vacuum sewers) are not dependent on gravity to move wastewater; thus there is less concern about the local topography. Moreover the system can be built with shallow trenches only and relatively small-diameter pipes. Thus pressurised sewers are an effective solution where conventional systems are impractical, e.g. in very hilly or flat areas, densely populated areas or where the groundwater table is high. However, pressurised sewers require a lot of pumps relying on electricity supply and make the system more vulnerable to failure. Thus if the topography, climate, country do/does not require pressurised sewers other systems such as simplified and condominal sewers, solids free sewers or separate sewers or conventional sewers may be preferable.

Pressure sewer unit including grinder and pump

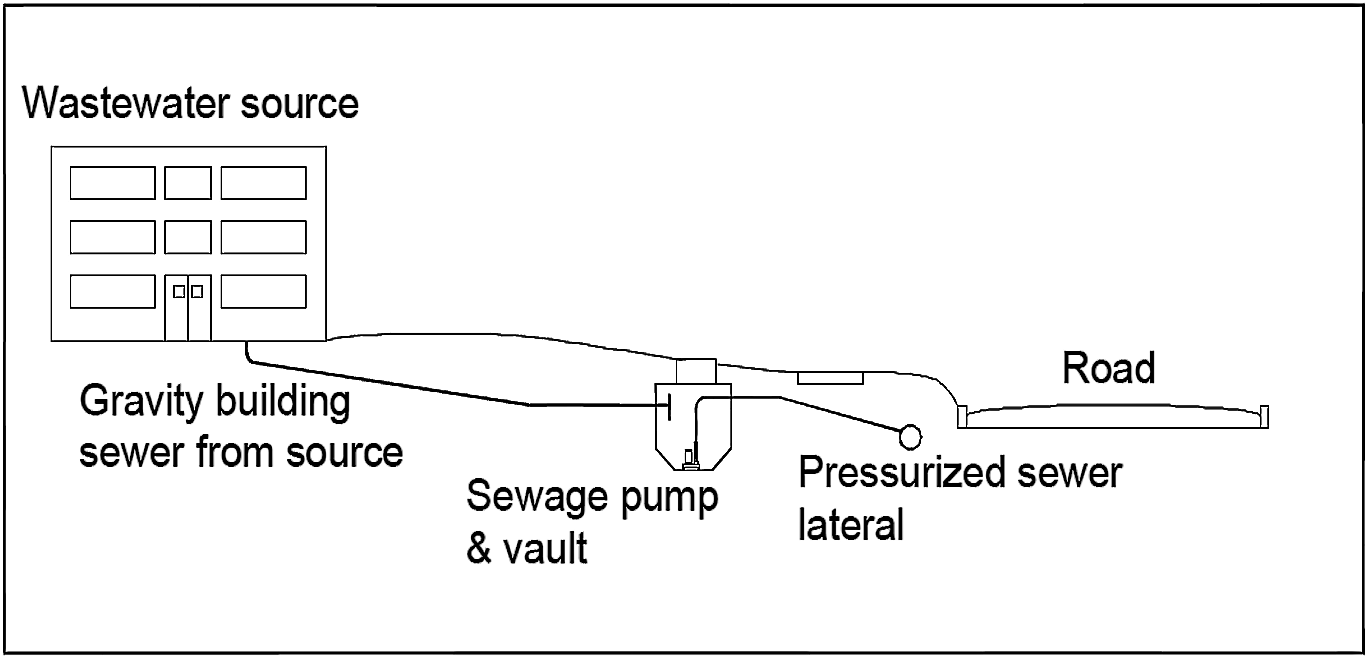

A typical arrangement for a network of pressurised sewers is for each connection (or small cluster of connections) to have a tank that receives wastewater. When the tank fills to a set point, a pump within the basin injects the wastewater further into the sewer. This transfer of wastewater pressurises the sewer. As various pumps along the length of the sewer inject sewage into the line, the wastewater is progressively moved to the treatment facility (WERF 2010).

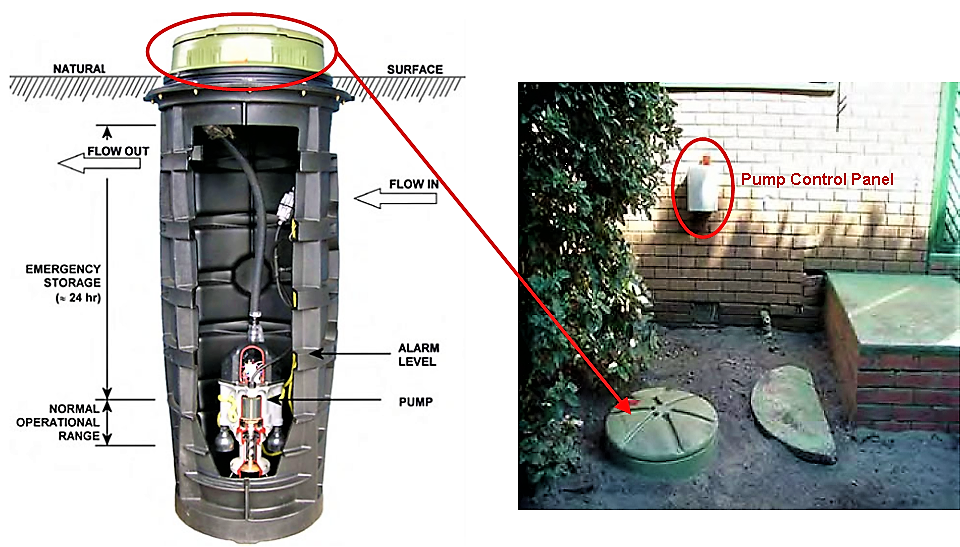

The storage tank at the entrance of the system is the heart of the system. It is generally a prefabricated plastic pit that provides wastewater storage, grinding (this allows small diameter piping after the pressure sewer unit) and pumping all in one in a single self-contained unit (see picture below). This all-in-one tank is called a pressure system unit. The wastewater flows first by gravity downhill into the pressure system unit from where it is grinded and then pumped into the sewer, generating the pressure. The unit is installed in a property in consultation with the owner. A small diameter discharge pipe goes from the unit to the pressure sewer pipe into the street. A small box (boundary kit) is installed just inside the property on the discharge pipe. A non-return valve (to prevent backflow from the pressure sewer) and isolation valve is housed in this kit. The unit is wired to the household power supply and controlled by a small panel located near the unit (control panel), either on a wall, fence or pole (SHOALHAVEN n.y.).

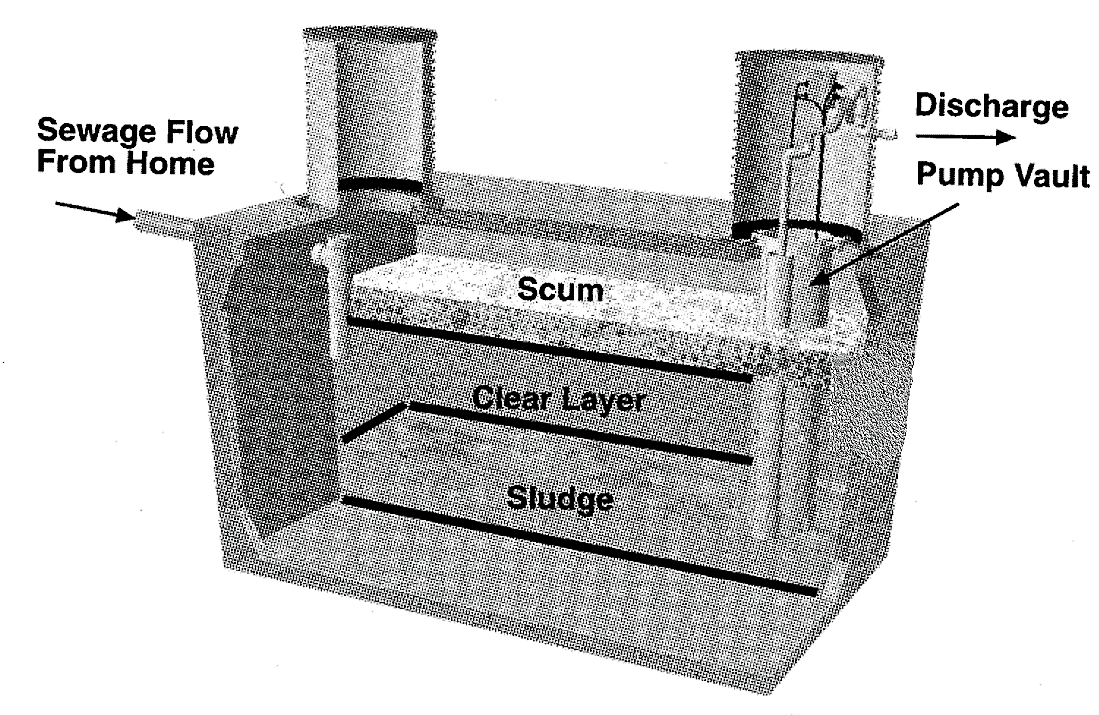

Septic tank effluent pump

An alternative to the all in one pressure sewer unit described above is to first install a septic tank situated outside in the ground or in the basement of the building to settle the solids. The septic tank effluent then flows in an underground holding tank containing a pump and control devices from where it is then pumped into the pressurised sewer system and transferred for treatment. Retrofitting existing septic tanks in areas served by septic tank/leach field systems would seem to present an opportunity for cost savings, but a large number (often a majority) must be replaced or expanded over the life of the system because of insufficient capacity, deterioration of concrete tanks, or leaks. The pump in this system does not have to be as powerful as grinder pump, since it just pumps liquid (U.S. EPA 2002).

Costs considerations

The cost of a pressure sewer system can be divided into two major components: The on-lot costs and the collection network costs. On-lot costs include the pump, basin, controls, building sewer, lateral piping, electrical service, and installation. The collection network includes all the piping in the utility easements that directs the sewage to the treatment facility. Depending on the style of pump and basin selected by the managing utility, on-lot costs are estimated to be US$ 4,800 to US$ 7,200 (prices are estimated for the United States of America, 2009 dollars) for an existing single-family home. Typical solids-handling pumps will use less than 1 kW-hr of power per day and the electrical cost would be about 50 dollars per year depending upon local electrical rates (prices are estimated for the United States of America, 2009 dollars). Using many low power-consuming pumps reduces installation cost as compared to a conventional gravity system (e.g. conventional sewers) that may require one or more large-capacity lift stations (sewer pumping stations) as conventional large scale systems barely can be operated by gravity only. A pressurised system also allows more flexibility in choosing locations for and routes to treatment facilities (adapted from WERF 2010).

Operation and maintenance

Regular service is important for all system components to ensure best long term performance to protect public health and the environment. This also protects the investment. Frequency of operation and maintenance is dependent upon wastewater volume, relative risk to public health and the environment as well as the complexity of components used (Adapted from WERF 2010). Electricity needs to be available all the time, the pumps should be checked regularly and the pipe connections should be controlled for leakages.

At a glance

| Working principle | A pit containing a grinder and pump or a settling unit (septic tank) connected to a holding tank with a pump are installed close to the user interface (single household to an apartment building). When a certain level of effluent has been collected, it is pumped into the sewer, generating the pressure for transportation. |

| Capacity/adequacy | Can be used in densely populated areas and where the groundwater table is high. It is independent from the topography (hilly or flat area) and can pass any obstacles without any problems. |

| Performance | High performance |

| Costs | High capital costs, but still lower than gravity sewer system |

| Self-help compatibility | Very low |

| O&M | Electricity required. The components and especially the pumping and piping must be inspected and maintained regularly to avoid and/or repair any damages. |

| Reliability | If well maintained it is reliable |

| Main strength | Shallow trenches, independent from topography and it requires a small amount of flushing water. Very high level of comfort and hygiene. |

| Main weakness | It is costly and it needs a permanent energy source for the grinder pumps. It needs expert design and depends on a centralised system. |

Basically, pressurised sewer systems have the same advantages as vacuum sewers. Therefore they are used in similar surroundings;

- Hilly or flat topography: gravity systems demand installation at great depths to maintain adequate flow or requires pumping and lift stations

- Rock layers, running sand or a high groundwater table make deep excavation difficult

- Densely populated areas

- High groundwater table

Flygt Pressurized Sewage Systems - For homeowners, residential associations and professionals

This paper is an overview about the Swedish company ITT Water & Wastewater about its pressurised sewage system.

ITT (n.y): Flygt Pressurized Sewage Systems - For homeowners, residential associations and professionals. Sundbyberg: ITT Water & Wastewater URL [Accessed: 29.05.2019]Pressure Sewer System.

The Schoalhaven City Council describes the system of pressurised sewering and its experiences.

SCHOALHAVEN WATER (n.y): Pressure Sewer System.. Shoalhaven: Shoalhaven City Council URL [Accessed: 29.05.2019]Pressure Sewer

This wastewater technology fact sheet is a detailed description of the pressurised sewer system. This factsheet describes the pressurised sewer system as an alternative option to conventional sewers. It describes the system as well as advantages/disadvantages, performance, costs and applicability.

U.S. EPA (2002): Pressure Sewer. Pennsylvania: United States Environmental Protection Agency (US EPA) URL [Accessed: 29.05.2019]Pressure Sewer System

This factsheet gives an overview about pressure sewer systems. It is illustrated with graphics and photos.

WERF (2010): Pressure Sewer System. Alexandria, Virginia: Water Environment Research Federation URL [Accessed: 29.05.2019]Common Failure Modes in Pressurised Pipeline Systems

This paper summarise the most common types of field failure modes in water supply mains and pressure sewers and associated fittings and appurtenances.

WSAA (2003): Common Failure Modes in Pressurised Pipeline Systems. Melbourne and Sidney: Water Services Association of Australia URL [Accessed: 29.05.2019]Low Pressure Sewer Systems Using Environment One Grinder Pumps

This technical document of the Environment One Corporation explains the possibilities with E/One low pressure system.

EONE (n.y): Low Pressure Sewer Systems Using Environment One Grinder Pumps. Niskayuna: Environment One Corporation URL [Accessed: 08.08.2011]Pressure Sewer

This wastewater technology fact sheet is a detailed description of the pressurised sewer system. This factsheet describes the pressurised sewer system as an alternative option to conventional sewers. It describes the system as well as advantages/disadvantages, performance, costs and applicability.

U.S. EPA (2002): Pressure Sewer. Pennsylvania: United States Environmental Protection Agency (US EPA) URL [Accessed: 29.05.2019]Flygt Pressurized Sewage Systems - For homeowners, residential associations and professionals

This paper is an overview about the Swedish company ITT Water & Wastewater about its pressurised sewage system.

ITT (n.y): Flygt Pressurized Sewage Systems - For homeowners, residential associations and professionals. Sundbyberg: ITT Water & Wastewater URL [Accessed: 29.05.2019]Design Criteria and Specifications for Pressure Sewers, Force Mains, Grinder Pumps and Appurtenances

These specifications give the minimum requirements for installation of pressure sewer lines, force mains and appurtenances in the City of Tullahoma, Tennessee.

TUB (2014): Design Criteria and Specifications for Pressure Sewers, Force Mains, Grinder Pumps and Appurtenances. Tullahoma: Tullahoma Utility Board (TUB) URL [Accessed: 29.05.2019]Pressure Sewer System

This factsheet gives an overview about pressure sewer systems. It is illustrated with graphics and photos.

WERF (2010): Pressure Sewer System. Alexandria, Virginia: Water Environment Research Federation URL [Accessed: 29.05.2019]Common Failure Modes in Pressurised Pipeline Systems

This paper summarise the most common types of field failure modes in water supply mains and pressure sewers and associated fittings and appurtenances.

WSAA (2003): Common Failure Modes in Pressurised Pipeline Systems. Melbourne and Sidney: Water Services Association of Australia URL [Accessed: 29.05.2019]Low Pressure Sewer Systems: Proven Performance and Lessons Learned

Between the years 1997 and 1998, almost 350 grinder pumps were installed along the waterfront property of in Kitsap County (Washington). This paper describes the proven performance and what they learned.

MAYHEW, C. (2005): Low Pressure Sewer Systems: Proven Performance and Lessons Learned. Port Orchard: West Sound Utility District. [Acessed: 08.08.2011] PDFEngineering Low Pressure Grinder Pump Sewer Systems

Kennedy/Jenks Consultants was asked to solve a common waterfront problem – failing septic systems. After analysing the situation, the experts chose a grinder pump system.

MAYHEW, C. FITZWATER, R. (1998): Engineering Low Pressure Grinder Pump Sewer Systems. United States: Kennedy/Jenks Consultants URL [Accessed: 29.05.2019]Pressure Sewer System.

The Schoalhaven City Council describes the system of pressurised sewering and its experiences.

SCHOALHAVEN WATER (n.y): Pressure Sewer System.. Shoalhaven: Shoalhaven City Council URL [Accessed: 29.05.2019]The Operation and Maintenance of Pressure Systems

Through a process of continual improvement the initial problems with the pressure sewer systems were identified and eliminated. This is the report.

GROGAN, G. (2007): The Operation and Maintenance of Pressure Systems. Shepparton: Water Industry Operators Association of Australia (WIOA) URL [Accessed: 08.08.2011]Rural Water Supply and Sanitation Challenges in Latin America for the Next Decade

Based on market research, this new WSP technical paper analyses the main features of the fecal sludge collection businesses in each city, including the marketing mix, potential demand, supply capacity, and legal frameworks. In addition, the paper spotlights major challenges and opportunities in fecal sludge management, describing the current and potential market for fecal sludge removal, collection, and disposal in peri-urban areas—which typically struggle with high population density, limited land planning, high citizen insecurity, and low coverage of basic services.

PEARCE-OROZ, G. (2011): Rural Water Supply and Sanitation Challenges in Latin America for the Next Decade. Lima: Water and Sanitation Program (WSP) URL [Accessed: 14.05.2012]Pressure Sewer Services Australia (PSSA)

This website has much information about the pressurised sewer system. The system is described, frequently asked questions are answered and case studies can be found.